Induction Brazing Diamond Drill

Views Send Enquiry

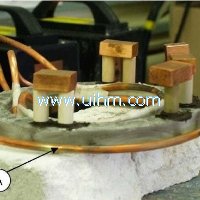

Objective To braze diamond inserts to a steel drilling ring

Material • steel ring and diamond inserts

• Braze shim preform

• Flux

Temperature 1300 – 1350 (700 – 730) °F (°C)

Frequency 68 kHz

Equipment Power of 35 kW, induction heating system, equipped with a remote heat station containing two 0.5 μF capacitors (total 0.25 μF) An induction heating coil designed and developed specifically for this application.

Process A multi-turn, internal-external helical coil is used to generate the required heating pattern. Initial tests on the ring alone determine system tuning. Flux is applied to the part and the braze shims are inserted into the counter-bored holes.

This is followed by the synthetic diamonds. The part is loaded into the coil and weight is placed onto the diamonds . RF power is applied until the braze flows. The power is turned off and the part air cools to room temperature.

Results/Benefits

• reduced ring warping compared to furnace heating

• decreased cycle time due to reduced ramp-up and cooldown times

Brazing Diamond Drill Show:

braze diamond inserts to a steel drilling ring 1

braze diamond inserts to a steel drilling ring 2

braze diamond inserts to a steel drilling ring 3

Related Content

induction brazing SS steel by handheld induction coil

induction brazing shoe mold

induction brazing drill bit of transformer

induction brazing stator

induction brazing top of condenser pipes by pancake induction coil

induction brazing SS steel parts with auto feed system by UHF induction heater

induction brazing oil tube

induction brazing N type cable connector

Hot

induction brazing SS steel by handheld induction coil

induction brazing shoe mold

induction brazing drill bit of transformer

customized RF induction heater for brazing works

induction brazing stator

water cooled flexible handheld induction coil for heating SS steel pipe

water cooled flexible handheld induction coil for heating SS steel pipes

UHF handheld induction heater for brazing copper

Newest Comment

No Comment

Post Comment