Induction Hardening Steel Cam

Views Send Enquiry

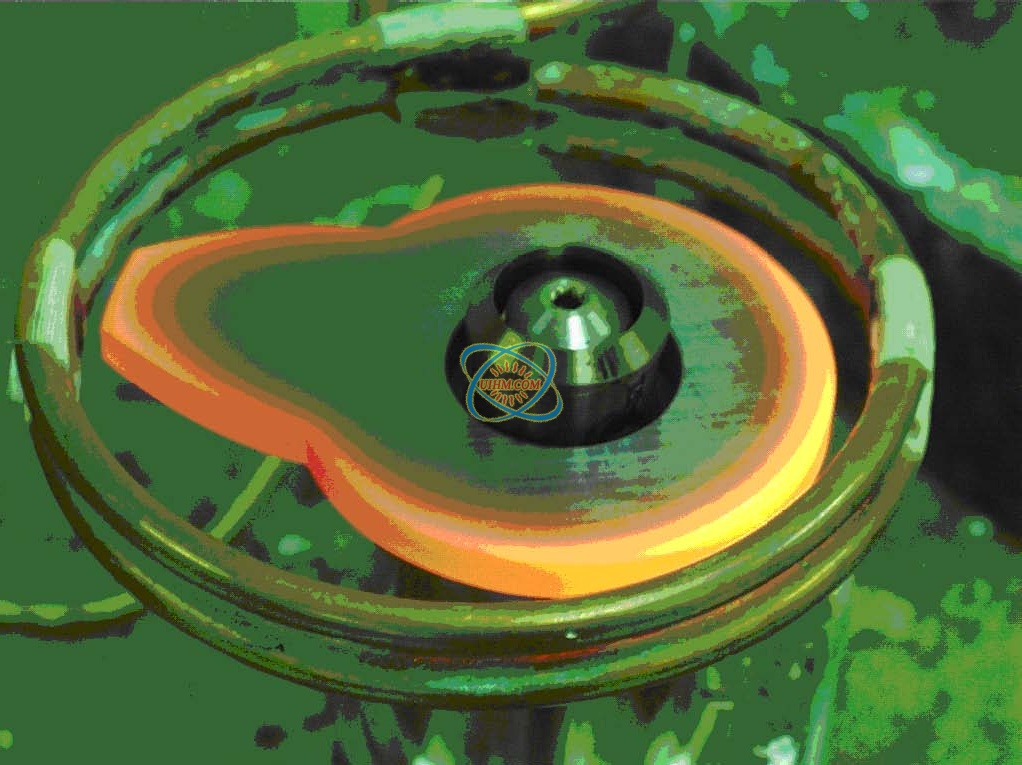

Objective To harden the perimeter of ¼” thick steel cam assemblies

Material ¼” thick steel cam assemblies of varying geometries

Temperature 1650 ºF (900 °C)

Frequency 177 kHz

Equipment Power of 20 kW, induction heating system, equipped with a remote heat station containing one 1.0μF capacitor and an induction heating coil designed and developed specifically for this application

Process A two-turn helical coil is used to heat the cams. The heat time varies from 120-150 seconds. After heating, the parts are quenched in water.

Results/Benefits Hardening the cam outer surfaces with induction results in:

• uniform heating for uniform results

• one coil can be used for many geometries

• consistent results from piece to piece

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction hardening surface of steel plate

induction hardening gear surface

induction hardening wheel gears

induction hardening TCT knife (tungsten carbide tool)

induction hardening knife edge (sickle blade)

induction hardening inner surface of steel pipe

induction hardening inner surface of steel ring by UHF induction heater

induction hardening inner surface of gear

Newest Comment

No Comment

Post Comment