Induction Shrink Fit Camshaft Gear

Views Send Enquiry

Objective: Heating a camshaft gear with a bore size of 1.630″ to shrink fit over a steel shaft that has a diameter of 1.632″. A temperature of 5000F is required for the gear to expand 0.002″ in order to slip over the shaft. Production is presently done at a rate of 15-20 gears per 24 hour shift by heating the gear on a hot plate. The hot plate heating cycle lasts for approximately 45 minutes.

The customer would like to explore the options available in terms of heating times and machine size.

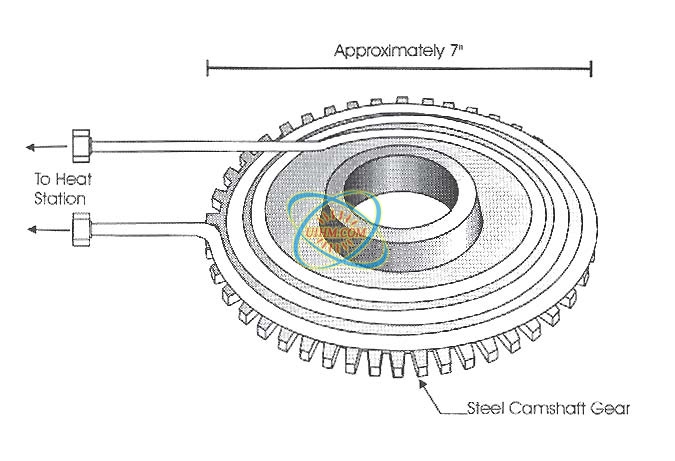

Material: Steel Camshaft Gear measuring 7″ in diameter, 1″ thick, with a bore size of 1.630″.

Temperature: 5000F

Application: A unique three (3) turn helical coil along with the various UIHM solid state induction power supplies were used to achieve the following

results:

*5000F was reached in three (3) minutes while using the Power of 25KW,25 kW output solid state induction power supply.

* 5000F was reached in five (5), eight (8), and ten (10) minutes using the Power of 25KW,25 kW output solid state induction power supply.

*Even heating was observed as a result of the unique three (3) turn helical induction coil.

Equipment: Power of 25KW,25 kW output solid state induction power supplies respectively, including remote heat stations and a unique three turn helical coil made from 3/16″ copper tubing and having a 4.4″ inside diameter.

Frequency: 50 kHz

shrink fit Camshaft Gear

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction heating inner surface

induction shrink fitting aluminium motor frame

induction shrink fitting coupling hub for oil pipes project by water cooled flexible induction coil

induction shrink fitting aluminum motors stators rotors

induction shrink fitting aluminum motors stators rotors

induction shrink fitting aluminum motors

induction shrink fitting aluminum motor frames to 350 celsius degree in 50 seconds by 60KW machine

induction shrink fitting

Newest Comment

No Comment

Post Comment