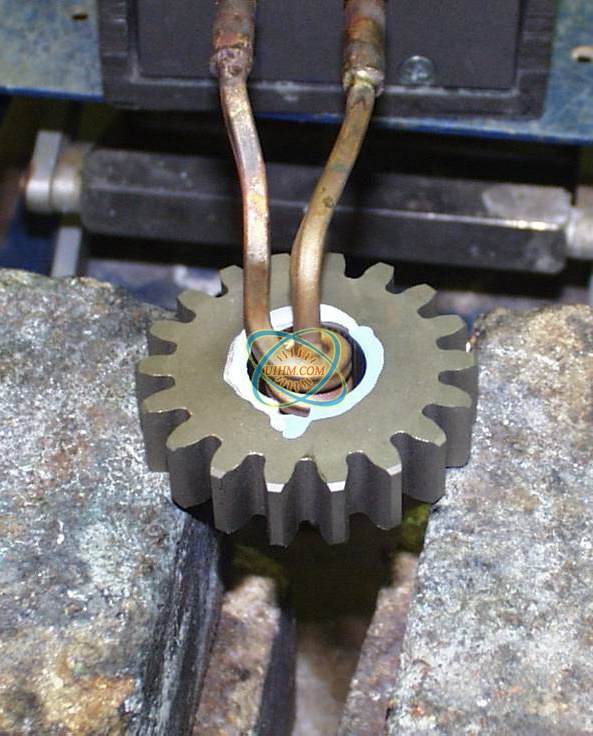

Induction Shrink fit steel gear

Views Send Enquiry

Objective Heat the bore of a hardened spur steel gear to shrink fit onto a gear motor shaft. This is part of a chair for the disabled.

Material Steel gear 2.5″ h (63.5mm) OD, .75″ h (19mm) ID x .625″ h (16mm) thick, temperature indicating paint

Temperature 400 oF (204 oC)

Frequency 30 kHz

Equipment .Power of 15 kW induction heating system, equipped with a remote workhead containing two 0.66 ƒÊF capacitors for a total of 1.32 ƒÊF

. An induction heating coil designed and developed specifically for this application.

Process A four turn helical internal coil is used to heat the gear bore. The coil is inserted into the gear bore and power is applied for 10 seconds to reach the required 400 oF (204 oC) and expand the gear bore. The gear is then placed on the shaft and allowed to cool, creating the shrink fit between the gear and the shaft.

Results/Benefits Induction heating provides:

. No pre-heat cycle, heat is available on demand

. Energy efficient, heats only the part, not the atmosphere around it

. Controlled, even distribution of heating

. Faster production times

shrink fit steel gear

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction heating inner surface

induction shrink fitting aluminium motor frame

induction shrink fitting coupling hub for oil pipes project by water cooled flexible induction coil

induction shrink fitting aluminum motors stators rotors

induction shrink fitting aluminum motors stators rotors

induction shrink fitting aluminum motors

induction shrink fitting aluminum motor frames to 350 celsius degree in 50 seconds by 60KW machine

induction shrink fitting

Newest Comment

No Comment

Post Comment