La inducción de recocido aliviar el estrés

Views

- Intro: Aliviar el estrés, y el alivio de normalización de RelievingStress ANNEALINGStress se aplica a ambas aleaciones ferrosos y no ferrosos y tiene por objeto eliminar las tensiones residuales internas generadas por los procesos de fabricació…

STRESS RELIEVING,NORMALISING AND ANNEALING

STRESS RELIEVING,NORMALISING AND ANNEALING

Stress Relieving

Stress relieving is applied to both ferrous and non-ferrous alloys and is intended to remove internal residual stresses generated by prior manufacturing processes such as machining, cold rolling and welding. Without it,

subsequent processing may give rise to unacceptable distortion and/or the material can suffer from service

problems such as stress corrosion cracking. The treatment is not intended to produce significant changes in

material structures or mechanical properties, and is therefore normally restricted to relatively low temperatures.

Carbon steels and alloy steels can be given two forms of stress relief:

(1) Treatment at typically 150-200°C relieves peak stresses after hardening without significantly reducing hardness

(e.g. case-hardened components, bearings, etc.):

(2) Treatment at typically 600-680°C (e.g. after welding, machining etc.) provides virtually complete stress relief.

Non-ferrous alloys are stress relieved at a wide variety of temperatures related to alloy type and condition. Alloys

that have been age-hardened are restricted to stress relieving temperatures below the ageing temperature.

Austenitic stainless steels are stress relieved below 480°C or above 900°C, temperatures in between reducing

corrosion resistance in grades that are not stabilised or low-carbon. Treatments above 900°C are often full solution anneals.

Normalising Applied to some, but not all, engineering steels, normalising can soften, harden or stress relieve a

material, depending on its initial state. The objective of the treatment is to counter the effects of prior processes, such as casting, forging or rolling, by refining the existing non-uniform structure into one which enhances

machinability/formability or, in certain product forms, meets final mechanical property requirements. A primary

purpose is to condition a steel so that, after subsequent shaping, a component responds satisfactorily to a

hardening operation (e.g. aiding dimensional stability). Normalising consists of heating a suitable steel to a

temperature typically in the range 830-950°C (at or above the hardening temperature of hardening steels, or above

the carburising temperature for carburising steels) and then cooling in air. Heating is usually carried out in air, so

subsequent machining or surface finishing is required to remove scale or decarburised layers.

Air-hardening steels (e.g. some automotive gear steels) are often “tempered” (subcritically annealed) after normalising to soften the structure and/or promote machinability. Many aircraft specifications also call for this combination of treatments. Steels that are not usually normalised are those which would harden significantly during air cooling (e.g. many tool steels), or those which gain no structural benefit or produce inappropriate structures or mechanical properties (e.g. the stainless steels).

Annealing

The primary purpose of an annealing treatment is to reduce the hardness of a material and facilitate the

progress of subsequent manufacturing operations. Annealing is commonly used after casting, forging or

rolling to soften materials and minimise residual stresses, improve machinability, and increase ductility by carefully controlling the microstructure. Many steels in strip form are annealed, as are most tool steels and stainless steels. Non-ferrous alloys are also annealed. There are several process variations that qualify as annealing treatments:

• Full annealing is performed on steels by heating to a high temperature (typically 830-950°C), then cooling

slowly to ambient temperature. Non-ferrous materials are softened and refined by full annealing at temperatures appropriate for each alloy.

• Isothermal / cyclic annealing is performed by heating steels to the full annealing temperature, cooling to an

intermediate temperature (typically 550-700°C) and soaking for a long period to allow transformation to

proceed slowly, followed by cooling to ambient temperature.

• Intercritical annealing is applied by heating steels to below the full annealing temperature (typically 723-

910°C) according to composition. A prolonged soak is followed by cooling to ambient temperature.

• Subcritical annealing takes place at a temperature for steels of typically 650-720°C, allowing a prolonged soak before cooling to ambient temperature.

• Homogenisation annealing can be applied to both ferrous and non-ferrous materials and is a prolonged

high-temperature soak intended to break down segregation in the material’s structure.

• Solution annealing is applied commonly to austenitic stainless steels, typically at 1010-1150°C. With

unstabilised grades, the treatment must be followed by fast cooling or quenching. It is applied as a softening

process during manufacture or to optimise corrosion resistance (e.g. after welding).

WHAT ARE THE BENEFITS?

Stress relieving, normalising and annealing all prepare metals and alloys for further processing or for the

intended service conditions. They control the ability of materials to be machined with ease, perform without

distortion in service, be formed without cracking or splitting, be subsequently hardened or carburised with

minimal distortion, or to resist corrosive environments.

WHAT SORT OF MATERIALS CAN BE TREATED?

All commercial alloys can be annealed and stress relieved. Normalising is restricted to certain steels for the

reasons indicated above.

WHAT ARE THE LIMITATIONS?

• Stress relieving of carbon or low-alloy steel fabrications is frequently the last heat treatment applied, so it must

be ensured that the mechanical properties of the materials treated will not be adversely affected.

• Stress relieving between machining operations can be

performed on pre-treated material. The stress relieving effectiveness may have to be reduced to prevent loss

of mechanical properties.

• Many austenitic stainless steels require fast cooling after high-temperature stress relief or solution

annealing. A degree of distortion or reintroduction of residual stresses is inevitable in such cases.

• The size and shape of items that can be stress

relieved, annealed or normalised depends on the type of equipment operated by the heat treater. For large

items, check the availability of suitably-sized facilities at an early stage.

WHAT PROBLEMS COULD ARISE?

• Most stress relieving operations are carried out in air, but protective media are also available. In air, alloys are subject to discolouration or scaling depending on the alloy and temperature used. Post-treatment cleaning may therefore be required.

• Normalising is usually performed in air on semifinished steel products where scaling and decarburisation pose no problems because they are removed by subsequent machining. A protective medium may sometimes be necessary; e.g. when normalising final-size products prior to localised surface hardening.

• Annealing processes can take place in air or in protective media such as molten salt, controlled gaseous atmospheres or vacuum. Prolonged soaks, as required by some annealing operations, necessitate the selection of a protective medium.

• There is always a risk of distortion/sagging when high-temperature treatmentsse aplican a personas vulnerables

los vasos de pared delgada o componentes grandes y pesados. Su tratador de calor tenga utilizar soportes especiales o accesorios para combatir este problema.

¿CÓMO ESPECIFICO?

Toda la información siguiente debe incluirse si es posible. Si no está seguro, pregunte a su tratador de calor antes de producir una especificación:

• El proceso necesario: esto podría ser estrés aliviar, normalizar o recocido; indicar si es necesario tratamiento brillante, o si el tratamiento en aire es satisfactoria.

• Tipo de material, grado y la norma de que se dibuja, con dibujo, composición y certificado del molino

cuando sea posible.

• Las normas generales aplicables (nacionales, internacionales o empresa) que contienen información relevante que

deben respetarse.

• Condición existente; por ejemplo los detalles de cualquier tratamiento térmico previo, como el endurecimiento y el Temple, el tratamiento de solución y envejecimiento, pretenden establecer propiedades mecánicas o de otras.

• El nivel de propiedades mecánicas requeridas. Generalmente un rango de dureza o resistencia a la gama

pueden citarse de la norma que se está trabajaba para. No es posible conocer una figura específica debido a la

variables ajenas a de la tratador calor (por ejemplo en recocido para eliminar los efectos de trabajo frío severo). A

nivel máximo de la dureza se solicita a menudo materiales normalizados o recocidos. Estándares como

BS 10083-1 y BS 970 ofrecen información sobre algunos aceros.

• El tipo de prueba requerida; por ejemplo, dureza (Vickers, Brinell), resistencia a la tracción etc. y cualquier ubicación especial para la prueba o la extracción de muestras para probetas.

• Requisitos para certificados especiales ni datos que proporcionará su tratador de calor.

• Otros servicios requeridos; por ejemplo enderezado (con límites de trabajo), limpieza/voladura, laboratorio o servicios especializados de NDT etc..

¿A DÓNDE VOY?

Para localizar el calor Tratadores ofreciendo el estrés, aliviar, normalizar o recocido servicios, consultar la corriente

edición de la guía del comprador de la CHTA. Es recomendable involucrar a su tratador de calor en una etapa temprana.

Recommended

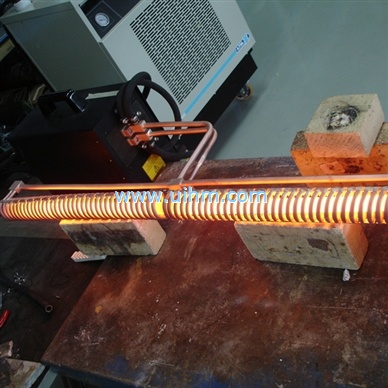

La inducción de acero recocido eje

Recocido un proceso de calentamiento efectiva

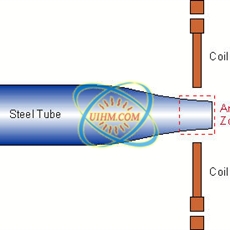

de calentamiento por inducción para cañones

partes de máquina de inducción totalmente automático

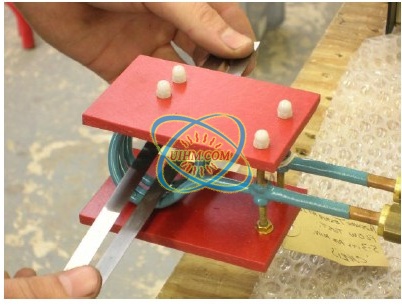

inducción tratamiento de recocido

Inducción de tubos de acero recocido

Motor de inducción de recocido del eje

La inducción de recocido tubos de aluminio

Newest Comment

No Comment

Post Comment