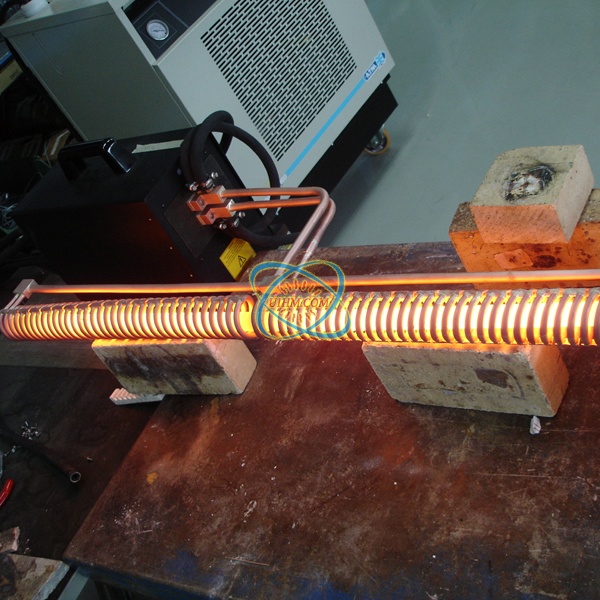

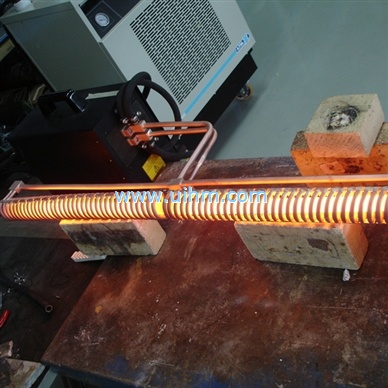

There are different types of heat treatment procedures offered by various companies in the market. Few of them are widely applied and are extremely effective. One of the efficient heat treatment procedures is annealing. This process supports an entire industry and has benefited various other industries across the globe. This heat treatment procedure has helped in enhancing the quality of steel used across the world. It is one of the significant contributions that have taken place in the field of science.

It is a procedure to enhance the machinability of steel. Through this process, steel is heated to a temperature of 723 degrees Centigrade after which it is left for cooling. There are five types of Annealing: Full, Process, Stress Relief, Spherodise, and Isothermal. The ideal temperature for the annealing process is generally a temperature, which is selected between the higher and the lower end of a particular range. However, the important part is that you keep the temperature steady for a certain period.

In the annealing process, when the glass is in a particular temperature for a specific span of time it is known as soaking. When the glass is soaked in a greater temperature then the benefit is that it needs a shorter time span for the stress to dissolve. However, sometimes it may distort under the pressure of heat. It will need longer time to cool down than it would have taken when annealed at a temperature, which is much lower.

Some of the basic advantages of this efficient process that one should be aware of are as follows: This procedure helps to augment the toughness in steel and increase its ductility. It helps to soften the steel and develop homogeneity of the material. Lastly, the steel is prepared in such a way it is geared up for advance heat treatment. Besides this, there are other heat treatment process that one can avail they are Stress relieving, Case hardening, Carburising, Homogenising, Carbonitriding, Shot Blasting, Induction hardening, and Tempering.

The environment, which is required for the process is extremely critical. When steel is being annealed, it needs a carbon-rich environment that facilitates carburization. However, if you are to avoid such defects then this procedure is ought to be carried out in an environment that is completely devoid of any such elements.

There are many companies in the market, which provide heat treatment processes at an extremely affordable price. Nevertheless, one must always go for the reputed ones and which has years of experience in this concerned field. For detailed information regarding such companies, you can refer the Internet.

The Internet will provide you with all the relevant information, review, and comments, regarding this effective heat treatment process, which will help you to make the correct decision. It is better to find out more on this issue before you choose any particular company for annealing process of treatment. It is one of the most popular and effective forms of heating and hence widely used.

It is a procedure to enhance the machinability of steel. Through this process, steel is heated to a temperature of 723 degrees Centigrade after which it is left for cooling. There are five types of Annealing: Full, Process, Stress Relief, Spherodise, and Isothermal. The ideal temperature for the annealing process is generally a temperature, which is selected between the higher and the lower end of a particular range. However, the important part is that you keep the temperature steady for a certain period.

In the annealing process, when the glass is in a particular temperature for a specific span of time it is known as soaking. When the glass is soaked in a greater temperature then the benefit is that it needs a shorter time span for the stress to dissolve. However, sometimes it may distort under the pressure of heat. It will need longer time to cool down than it would have taken when annealed at a temperature, which is much lower.

Some of the basic advantages of this efficient process that one should be aware of are as follows: This procedure helps to augment the toughness in steel and increase its ductility. It helps to soften the steel and develop homogeneity of the material. Lastly, the steel is prepared in such a way it is geared up for advance heat treatment. Besides this, there are other heat treatment process that one can avail they are Stress relieving, Case hardening, Carburising, Homogenising, Carbonitriding, Shot Blasting, Induction hardening, and Tempering.

The environment, which is required for the process is extremely critical. When steel is being annealed, it needs a carbon-rich environment that facilitates carburization. However, if you are to avoid such defects then this procedure is ought to be carried out in an environment that is completely devoid of any such elements.

There are many companies in the market, which provide heat treatment processes at an extremely affordable price. Nevertheless, one must always go for the reputed ones and which has years of experience in this concerned field. For detailed information regarding such companies, you can refer the Internet.

The Internet will provide you with all the relevant information, review, and comments, regarding this effective heat treatment process, which will help you to make the correct decision. It is better to find out more on this issue before you choose any particular company for annealing process of treatment. It is one of the most popular and effective forms of heating and hence widely used.

annealing

Newest Comment

No Comment

Post Comment