The induction heating from the Faraday discovered phenomenon of electromagnetic induction, that is, the alternating current in the conductor generates an induction current, resulting conductor heating. Swedish technical staff in 1890 invented the first induction melting furnace - Slotted core furnace, 1916, the Americans invented the closed slot core furnace from induction heating technology gradually entered the practical stage.

The 20th century, the rapid development of power electronic devices and technology, which greatly promoted the development of induction heating technology.

In 1957, the United States developed a thyristor as power electronic devices milestone, marking the beginning of modern power electronics technology, also led to the induction heating technology revolution. 1966, Switzerland and West Germany First thyristor developed induction heating device, from the beginning of the induction heating technology rapid development.

1980s, the power electronic devices again the rapid development of the GTO, MOSFET, IGBT, M CT and SIT devices have appeared. Gradually abandoned thyristor induction heating device and start using these new devices. Now commonly used IGBT and MOSFET, IGBT for high power occasions, occasions MOSFET for higher frequencies. According to reports, can be used abroad IGBT induction heating devices to do more than 1000kW power, frequency exceeds 50kHz. The MOSFET is more suitable for high frequency applications, usually used in a few kilowatts of medium power applications, the frequency above 500kHz, and even a few megahertz. However, foreign also launched using MOSFET high-power induction heating device, such as the device developed by the United States 2000kW / 400kHz.

Real application of induction heat treatment technology in China began in 1956, the former Soviet Union, the introduction of the main applications in the automotive industry. With the power equipment manufacturing in the 20th century, the induction hardening process equipment followed to develop. The domestic induction hardening process equipment manufacturing industry expanding product variety, original equipment imports, gradually replaced by domestic products, save foreign exchange for the country at the same time, the development of domestic enterprises. Induction heating manufacturing services mainly the automotive manufacturing industry, and the modern metallurgy industry in the future will have greater demand for induction heating.

, Induction heating characteristics

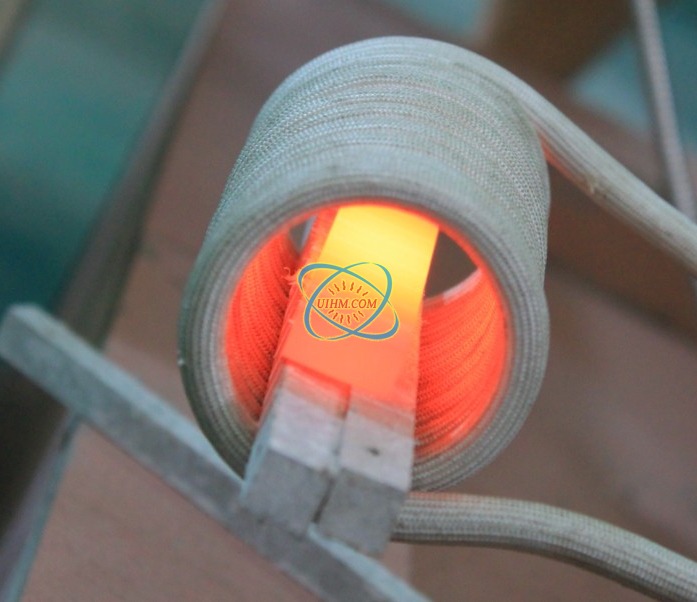

Induction heating technology with a fast, clean, energy-saving, easy to automate and online production, high production efficiency, is an internal heat source, is a non-contact heating method can provide a high power density on the heating surface and depth, a highly flexible choice , can work in a variety of carrier gas (air, protective gas and vacuum), extremely low loss, does not produce any physical pollution, environmentally friendly and sustainable approach to development, is one of the green eco-friendly heating process. Controlled atmosphere heat treatment, vacuum heat treatment no less oxidation technology has become the mainstream of development of heat treatment technology.

Its main applications are:

(1) metallurgy of non-ferrous metals smelting, metal materials, heat treatment, forging, extrusion, rolling profile production through heat weld pipe production.

(2) the quenching of the various mechanical parts of machinery manufacturing, and after quenching, tempering, annealing, normalizing heat treatment heating; hot pressure processing through before.

(3) Light cans and other packaging sealing, such as name of Tetra seal packaging.

(4) The electronic tubes vacuum degassing heating.

(5) for special applications such as plasma surfacing.

FAW, for example, in the production of mid-size cars, light trucks and cars, there are nearly 200 kinds of parts need to induction heating quenching process, from the shape and size of the induction heating quenching parts of view, can be regarded as a great variety in size and are there. With the induction hardening technology continues to evolve, induction hardening parts has risen to account for about 50% of all heat treated parts. The data show that China's automobile industry, the application of induction heat is entering the ranks of the world's advanced level.

Second, the induction heating New Process

Induction heating process is mainly reflected the level of induction heating technology, the basis for the development of technology, advanced induction heating technology can play an induction heating characteristics to achieve efficient, energy-saving local heat treatment.

(1) the longitudinal induction heating quenching Axle longitudinal induction heating quenching has been used in cars, tractors and industrial. Axle longitudinal heating time quenching. In Germany, the United States Axle quenching dedicated machine, heating, correction and quenching in a machine, improve productivity, a quenching with continuous quenching the same production equipment covers an area of 40m2 and 115m2 each.

(2) crankshaft the neck fillet quenching crankshaft neck Fillet Quenching, fatigue strength than normalizing the doubling, the the Cummins NH engine crankshaft produced in our country have adopted such a process.

(3) low hardenability steel gear quenching as early as the 1970s, our country was conducted 55DT, 60DT, 70DT steel research and achieved initial results, the future due to the steel hardenability instability, low quench steel not continue to be used for production. 1992, the founder of Russian low quench steel the, K.3ЩЕПЕ ЛЯКОВСКЦЦ Dr. to give lectures in China, and to a the steel mills survey smelting low quenching steel that the plant is fully equipped with the production of low-quenched steel conditions. YB 2009-1981 "a low hardenability containing titanium high-quality carbon structural steel" control of the alloying elements, unlike Russia, (Russian) 1054-74,58 (55П П) steel element content of Mn, Cr, Ni, Cu four elements of the requirements <0.5% (by mass) of the three elements of the provisions of Cr, Ni, Cu, YB2009-8155Ti steel <0.5% (by mass), which may be the key.

Russian low quench steel control hardenability steels have been widely used in the automotive, tractor axle gear, excavator gear, transmission cross shaft, train cars rolling bearings, automotive leaf spring and rail coil spring made great economic benefits .

(4) sensing resistor quenching is well known that the steering rack teeth using a sense resistor method of quenching, domestic imports of machine tools in production has been more than three. The British machines this process for gear production found after quenching gear basic deformation can subsequently enter the assembly process.

(5) fixed Hardening of the crankshaft journal new device called Gr ankproTM, and replace the 8-word semi-circular rotating heating induction with fixed heat sensor with two semi-circular. This set of equipment for quenching and tempering curved neck, compared with the old technology, energy-saving, small footprint, the advantages of small deformation of the workpiece and the long life of the sensor.

Third, induction heating power supply and technical

Thyristor IF replace the power machine generator. Early 1990s, domestic thyristor power plants has mushroomed everywhere, through the survival of the fittest competition, and now the production plant has tended to stabilize. Thyristor power to the IGBT transistor power tube high-frequency will be the development of a MOSFET transistor power, portable transistor super audio, high-frequency power supply market is extremely competitive, and its future will also who of high quality, high technical level, Who will be able to gain a firm foothold.

The domestic frequency power supply are parallel resonant inverter structure. Therefore, in the research and development of greater capacity parallel inverter frequency power supply while the developed structure is simple, easy to frequent starting series inverter frequency power supply problem is to be solved in the field of domestic intermediate frequency induction heating device, especially in the melting and casting applications series power inverter is easy to realize the full conditions of constant power output (in favor of lower electricity tons consumption) and machine load power distribution control, and more should be widely applied.

In the range of super audio (10 ~ 100kHz), due to the limitations of the the thyristor itself switching characteristics parameters, to the development of the band's power to bring a lot of technical difficulty. Zhejiang University in the 1980s using thyristor multiplier circuit developed 50kW / 50kHz audio power, using time division circuit developed 30kHz thyristor audio power, but because of the multiplier circuit dual resonant circuit coupled to the load is non-linear, time-varying heating load parameters of the resonant circuit parameters match debug complex and time division circuit controls and the complex structure of the main circuit, inverter tube utilization is low, and therefore did not get a very good promotion and application.

70-80 early modern semiconductor micro-integrated processing technology and power semiconductor technology combine, have developed a large number of full-controlled power electronic semiconductor devices (GTR, MOSFET, SIT, SITH and MCT, etc.) for all solid super audio , high-frequency power development has laid a solid foundation.

Band in the high-frequency (100kHz), currently abroad, is in a transition phase from traditional tube power supply to power all-solid-state transistor technology. Some Japanese companies using SIT, a 1000kW power levels reached in the late 1980s, 200kHz, 400kW, 400kHz.

Defects in Europe and the United States, the SIT exists a high on-state losses (SIT work in the unsaturated zone), high frequency power devices MOSFET. With modular MOSFET power devices, large capacity, MOSFET high frequency induction heating power supply capacity has been rapid development. Spain MOSFET current induction heating power supply manufacturing level up to 600kW, 400kHz, developed by Germany in 1989, the current-mode MOSFET induction heating power level of 480kW, 50 ~~ 200kHz current-mode MOSFET, the Belgium I nductoEiphiac produced induction heating power level can up to 1000kW, 15 ~ 600kHz. Zhejiang University in the 1990s developed a 20kW, 300kHz MOSFET high frequency power supply, has been successfully applied to the surface heat treatment of the small cutter and aircraft turbine blades heat stress assessment.

Intermediate frequency induction heating power thyristor the super audio band mainly uses IGBT in the high frequency band, the As SIT presence of high conduction losses and other defects, the major international development MOSFET power. Induction heating power resonant inverter power devices to achieve soft switching, but larger induction heating power supply usually power, power devices, passive components, cables, wiring, grounding and shielding are many special requirements. Thus, induction heating power high frequency still many applications, the basic technology needs to be further explored, especially the advent of the new type of high-frequency high-power devices (such as MCT, the IGBT and SIT power devices, etc.), will further promote the high-frequency induction heating power supply development.

Considered from the point of view of the circuit to the large capacity induction heating power supply, high-capacity technology can be divided into two categories: a class of devices in series and parallel; the other multiple bridges or power series and parallel. Devices in series and parallel manner, must be dealt with seriously tandem devices pressure problems and parallel devices flow problems due to the discrete nature of the device manufacturing process parameters, limiting devices in series and parallel number and serial number of parallel more, the worse the reliability of the device. Multiple power supply in series and parallel technology is further again in the device series and parallel technology based on the capacity of the effective means, by means of a reliable power series and parallel technology, in the case of the appropriate single capacity simply by series and parallel run manner large capacity devices, each single only one unit of the device (or a module).

The induction heating power inverter main parallel inverter and series inverter, the output of the inverter in series can be equivalent to a low impedance voltage source, when the two voltage sources are connected in parallel, between the amplitude, phase and frequency different or fluctuations will lead to a lot of circulation, as well as the the inverter device's current severe uneven the series inverter existence and machine expansion difficult; parallel inverters, inverter DC input of a large electric reactor AG / DG DG / DG link acts as a current buffer between the links of each parallel inverter, so that the input terminal has enough time to correct the deviation of the DC current to achieve the expansion of the multi-parallel transistorized super audio, high-frequency current the use of the structure of the parallel inverter parallel inverters easy modular, large capacity is a main reason.

Load object wide range of induction heating power supply, power inverter load is an organic whole, generally matching transformer connected to the power supply and the load sensor, high-frequency, ultra-audio matching transformer power from the magnetic material to the winding The structure is further optimized and improved, from the circuit topology with three passive components instead of two passive components to cancel the transformer to achieve efficient, low-cost matching.

Induction heating power thyristor, transistor and tube-type can be produced in the country. The thyristor power production applications for many years. IGBT power its advantages more and more users are using. MOSFET power supply, high efficiency, low pressure, but the price is high, and is gradually replacing the tube high-frequency power supply. Portable small high-frequency power supply due to inexpensive, convenient, domestic widely, even into foreign markets.

UHF power (> 1MHz), dependence on imports, domestic joint for several companies like UIHM production to address the needs of blades, saw blades and other special process.

Reliability requirements increase with the degree of automation and high-power induction heat treatment production line, the need to strengthen the development of the complete installation of the heating process. Induction heating systems forward the development of intelligent control direction, with computer intelligent interface, the control performance of remote control and automatic fault diagnosis system of induction heating power is becoming the next generation of development goals.