Objective Heat to melting point various materials in a nitrogen atmosphere in a graphite or molybdenum crucible.

Material Magnesium fluoride, tantalum pentoxide, aluminum, yttrium fluoride, germanium, hafnium or titanium dioxide and a Pyrex bell jar

Temperature Melting temperatures varies

Frequency 60 kHz

Equipment

• 45 kW induction heating system, equipped with a remote head machine containing two 1.0μF capacitors for a total of 0.5 μF

• 45 kW induction heating system, equipped with a remote head machine containing two 1.0μF capacitors for a total of 0.5 μF

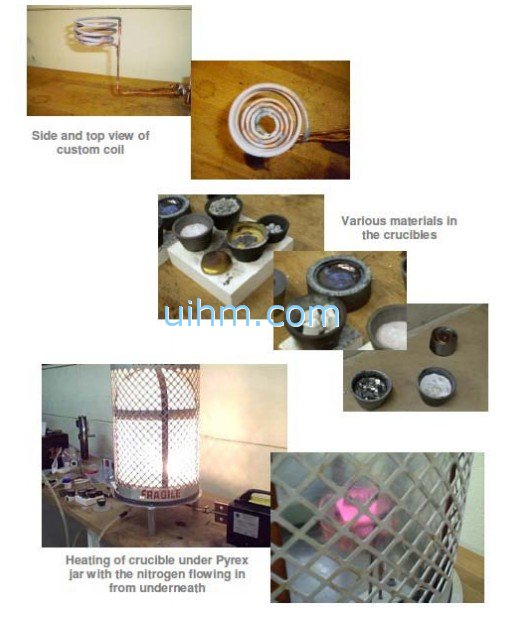

• An induction heating coil designed and developed specifically for this application.

Process The crucible is heated using a coil with a four turn pancake at the base that extends upward into a three turn helical coil.

Times and melting temperatures vary due to the properties of the different materials.

Results/Benefits Induction heating provides:

• Faster process time than electron beam heating.

• Repeatable, consistent results.

Even distribution of heating.

Crucible melting various materials in nitrogen atmosphere

Newest Comment

No Comment

Post Comment