Crucibles for Induction Melting

The proper crucible for melting of ferrous alloys is often viewed as a insignificant decision when, in reality, considerable effort should be given to this important decision. Crucible performance can have dramatic effects on foundry costs and the competitive ability of the shop. The melting crucible can affect the overall quality of the castings directly through scrap rates and it can also affect a shop’s labor costs necessary for frequently changed crucibles.

There are many variables that influence crucible performance. This article addresses many commonly overlooked variables that can have a dramatic impact on crucible performance and overall life.

The selection of the proper crucible forms the basis for extending crucible life and performance. This is easily accomplished by viewing the selection process first in three different ways and selecting the crucible that will best fulfill all conditions. It is important to understand that all of these considerations are interdependent and therefore, by changing one property or characteristic, you will likely affect another. Selecting a crucible is always a compromise and therefore, it is often necessary to experiment in order to find the most cost-effective solution for your particular shop.

Physical Considerations

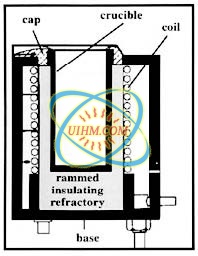

Proper fit of the crucible in your furnace is essential. The overall dimensions of the crucible should be such that there is sufficient room for ramming the backup material behind the crucible. If the area is too small (less than 1 inch), the backup ram may not be sufficiently dense, possibly causing the crucible to be inadequately supported, the thermal profile to be uneven, or most importantly, the induction coil to be poorly protected. When selecting a crucible, it is also important to consider wall and bottom thicknesses. Crucibles are often purchased with only the capacity in mind, yet thicker walls and bottoms can significantly increase crucible life and can reduce labor costs since change overs will be less frequent. A supplier with custom shape capabilities can modify an existing design to accommodate this option.

Chemical Considerations

Chemical considerations are often entirely overlooked when selecting a crucible for induction melting; yet this can be the most important consideration. Alumina crucibles, for example, are often used because of the ability to perform under a wide variety of melt chemistries; however, there can be considerable price and performance differences among this class of crucibles.

For best performance, chemical composition of the crucible must be compatible with the chemical composition of the melt. This is visualized by the childhood experiment of mixing vinegar (an acid) with baking soda (a base). The products chemically react and consume each other. Crucibles can also be defined as either acidic or basic as well. An acidic crucible in contact with a basic melt or slag will cause a chemical reaction that results in fast erosion of the crucible and possible inclusions in the melt.

Thermal Considerations

Thermal considerations are important because of the limitations of many materials. Consideration must be given to the rate at which metal is melted, the number of melts per day, and the maximum temperature at which melts are performed.

Although a ceramic is hard and brittle at room temperature, a crucible becomes plastic at operating temperatures because of the formation of liquid phases. The more plastic a material becomes, the more susceptible it is to erosion. If operating temperatures are high enough, an upgrade to a more refractory, less plastic material may be required.

In addition, once these liquid phases develop, they become glassy (amorphous) phases when they cool. Glassy phase ceramic is usually prone to thermal shock. Therefore, cycling can have a detrimental effect on crucible life. Repeated heating and cooling leads to crack formation and eventual failure of the crucible.

The Final Decision

The previously mentioned considerations should not be taken independently. A material with excellent thermal considerations will likely sacrifice desirable chemical and physical properties. When selecting the proper crucible, seek the best combination of physical, chemical and thermal properties rather than the best of each category.

Some operational considerations should also be addressed. For example, vacuum melting requires crucibles with certain chemical properties. Other atmospheric conditions may require additional consideration. Your crucible supplier should be your most valuable information source.

Newest Comment

No Comment

Post Comment