Induction heating technology used in home appliance on the early and later with high efficiency, energy saving and environmental advantages of growing significantly, with products using the technology is mature and stable, induction heating industry began to develop gradually from the earlier single-phase 2KW, and now the three-phase 100KW and above, in just a few years, induction heating technology and product applications with a qualitative leap. along with the device’s internal power components (eg, rectifier, IGBT modules, thin film capacitors, etc.) increasingly high demand for its reliability and stability determine the safety and use of equipment life. The typical internal structure of induction heating equipment movement Induction heating circuit is divided into two from the products on the market point of view, 30KW or less is used in more than half-.30 KW is used in full-bridge. 30KW movement with half-point of view, the use of film capacitors are as follows: DC-LINK :30-40?F (800VDC), multiple discrete capacitors in parallel mode (3-13 months) High resonance: arm 1.2-1.4?F (1600VDC), multiple discrete capacitors in parallel mode (3-14 months)Module using the advantages of film capacitors a movement within the main loop of the bypass process using copper structure, copper thickness is assured of the main flow back to passing ability, low-temperature copper bar. Installation is simple, convenient, fast, efficient and greatly reduce the error probability. b the main circuit only requires two copper strips, instead of the past a large PCB, the product material costs and labor costs, and greatly reduced, reliability is improved. eliminating the need for PCB plug-in, Tin stove, welding and other processes. c part of the main loop control with separate driver, so strong electrical / weak separation to reduce the primary resonant circuit of the chip-driven part of the interference of the product after-sales maintenance and other convenient, reusable components, reducing maintenance costs . d As capacitors are modular forms package, available aluminum heat, movement can be hermetically sealed solved the fumes, moisture, cockroaches, dust and other metals into the movement’s internal problems, improved product reliability and life. e by a number of discrete capacitors in parallel to form a single module, to solve the discrete capacitor over the uneven flow, partial pressure of inequality and other issues, shorten the distance of the main circuit line, reducing the line inductance on the power distribution components of the impact.Actual use of the capacitor module To test the aluminum cooling module internal temperature the resonant capacitor, the capacitor module in the production of samples into an internal NTC thermistor. A customer to use 2 * 0.8?F/1600VDC modules used in the half-bridge circuit 15KW induction cooker.From the measured data showed that the resonant capacitor module in the aging room at 25 ? and 40 ?, full power about 45 minutes of work, film capacitor internal temperature to stabilize, and with the increased working hours, the temperature has been stable down. Current DC-LINK capacitor module (MKP-LA) and high resonant capacitor module (MKPH-RA) through a number of co-operation with mass use, the Division has been creating electronic format of the series capacitor modules successfully applied for national patents.Summary IGBT can be made by the form of modules form a single tube, cooling effect, over-current capability in this Division Reference IGBT internal cooling structure, developed the structure of the capacitor with aluminum cooling module, used in induction heating devices. After more than co-unit quantities for use, has a lot to promote the use of 2010. With the induction heating equipment market demand continues to increase, the product more competitive. Enterprises to improve their products, market share, must invest human and material resources, the old product updates, technology upgrades, in order to enhance their competitive force

Induction heating technology used in home appliance on the early and later with high efficiency, energy saving and environmental advantages of growing significantly, with products using the technology is mature and stable, induction heating industry began to develop gradually from the earlier single-phase 2KW, and now the three-phase 100KW and above, in just a few years, induction heating technology and product applications with a qualitative leap. along with the device’s internal power components (eg, rectifier, IGBT modules, thin film capacitors, etc.) increasingly high demand for its reliability and stability determine the safety and use of equipment life. The typical internal structure of induction heating equipment movement Induction heating circuit is divided into two from the products on the market point of view, 30KW or less is used in more than half-.30 KW is used in full-bridge. 30KW movement with half-point of view, the use of film capacitors are as follows: DC-LINK :30-40?F (800VDC), multiple discrete capacitors in parallel mode (3-13 months) High resonance: arm 1.2-1.4?F (1600VDC), multiple discrete capacitors in parallel mode (3-14 months)Module using the advantages of film capacitors a movement within the main loop of the bypass process using copper structure, copper thickness is assured of the main flow back to passing ability, low-temperature copper bar. Installation is simple, convenient, fast, efficient and greatly reduce the error probability. b the main circuit only requires two copper strips, instead of the past a large PCB, the product material costs and labor costs, and greatly reduced, reliability is improved. eliminating the need for PCB plug-in, Tin stove, welding and other processes. c part of the main loop control with separate driver, so strong electrical / weak separation to reduce the primary resonant circuit of the chip-driven part of the interference of the product after-sales maintenance and other convenient, reusable components, reducing maintenance costs . d As capacitors are modular forms package, available aluminum heat, movement can be hermetically sealed solved the fumes, moisture, cockroaches, dust and other metals into the movement’s internal problems, improved product reliability and life. e by a number of discrete capacitors in parallel to form a single module, to solve the discrete capacitor over the uneven flow, partial pressure of inequality and other issues, shorten the distance of the main circuit line, reducing the line inductance on the power distribution components of the impact.Actual use of the capacitor module To test the aluminum cooling module internal temperature the resonant capacitor, the capacitor module in the production of samples into an internal NTC thermistor. A customer to use 2 * 0.8?F/1600VDC modules used in the half-bridge circuit 15KW induction cooker.From the measured data showed that the resonant capacitor module in the aging room at 25 ? and 40 ?, full power about 45 minutes of work, film capacitor internal temperature to stabilize, and with the increased working hours, the temperature has been stable down. Current DC-LINK capacitor module (MKP-LA) and high resonant capacitor module (MKPH-RA) through a number of co-operation with mass use, the Division has been creating electronic format of the series capacitor modules successfully applied for national patents.Summary IGBT can be made by the form of modules form a single tube, cooling effect, over-current capability in this Division Reference IGBT internal cooling structure, developed the structure of the capacitor with aluminum cooling module, used in induction heating devices. After more than co-unit quantities for use, has a lot to promote the use of 2010. With the induction heating equipment market demand continues to increase, the product more competitive. Enterprises to improve their products, market share, must invest human and material resources, the old product updates, technology upgrades, in order to enhance their competitive force Induction heating technology used in home appliance on the early and later with high efficiency, energy saving and environmental advantages of growing significantly, with products using the technology is mature and stable, induction heating industry began to develop gradually from the earlier single-phase 2KW, and now the three-phase 100KW and above, in just a few years, induction heating technology and product applications with a qualitative leap. along with the device’s internal power components (eg, rectifier, IGBT modules, thin film capacitors, etc.) increasingly high demand for its reliability and stability determine the safety and use of equipment life. The typical internal structure of induction heating equipment movement Induction heating circuit is divided into two from the products on the market point of view, 30KW or less is used in more than half-.30 KW is used in full-bridge. 30KW movement with half-point of view, the use of film capacitors are as follows: DC-LINK :30-40?F (800VDC), multiple discrete capacitors in parallel mode (3-13 months) High resonance: arm 1.2-1.4?F (1600VDC), multiple discrete capacitors in parallel mode (3-14 months)Module using the advantages of film capacitors a movement within the main loop of the bypass process using copper structure, copper thickness is assured of the main flow back to passing ability, low-temperature copper bar. Installation is simple, convenient, fast, efficient and greatly reduce the error probability. b the main circuit only requires two copper strips, instead of the past a large PCB, the product material costs and labor costs, and greatly reduced, reliability is improved. eliminating the need for PCB plug-in, Tin stove, welding and other processes. c part of the main loop control with separate driver, so strong electrical / weak separation to reduce the primary resonant circuit of the chip-driven part of the interference of the product after-sales maintenance and other convenient, reusable components, reducing maintenance costs . d As capacitors are modular forms package, available aluminum heat, movement can be hermetically sealed solved the fumes, moisture, cockroaches, dust and other metals into the movement’s internal problems, improved product reliability and life. e by a number of discrete capacitors in parallel to form a single module, to solve the discrete capacitor over the uneven flow, partial pressure of inequality and other issues, shorten the distance of the main circuit line, reducing the line inductance on the power distribution components of the impact.Actual use of the capacitor module To test the aluminum cooling module internal temperature the resonant capacitor, the capacitor module in the production of samples into an internal NTC thermistor. A customer to use 2 * 0.8?F/1600VDC modules used in the half-bridge circuit 15KW induction cooker.From the measured data showed that the resonant capacitor module in the aging room at 25 ? and 40 ?, full power about 45 minutes of work, film capacitor internal temperature to stabilize, and with the increased working hours, the temperature has been stable down. Current DC-LINK capacitor module (MKP-LA) and high resonant capacitor module (MKPH-RA) through a number of co-operation with mass use, the Division has been creating electronic format of the series capacitor modules successfully applied for national patents.Summary IGBT can be made by the form of modules form a single tube, cooling effect, over-current capability in this Division Reference IGBT internal cooling structure, developed the structure of the capacitor with aluminum cooling module, used in induction heating devices. After more than co-unit quantities for use, has a lot to promote the use of 2010. With the induction heating equipment market demand continues to increase, the product more competitive. Enterprises to improve their products, market share, must invest human and material resources, the old product updates, technology upgrades, in order to enhance their competitive force

Induction heating technology used in home appliance on the early and later with high efficiency, energy saving and environmental advantages of growing significantly, with products using the technology is mature and stable, induction heating industry began to develop gradually from the earlier single-phase 2KW, and now the three-phase 100KW and above, in just a few years, induction heating technology and product applications with a qualitative leap. along with the device’s internal power components (eg, rectifier, IGBT modules, thin film capacitors, etc.) increasingly high demand for its reliability and stability determine the safety and use of equipment life. The typical internal structure of induction heating equipment movement Induction heating circuit is divided into two from the products on the market point of view, 30KW or less is used in more than half-.30 KW is used in full-bridge. 30KW movement with half-point of view, the use of film capacitors are as follows: DC-LINK :30-40?F (800VDC), multiple discrete capacitors in parallel mode (3-13 months) High resonance: arm 1.2-1.4?F (1600VDC), multiple discrete capacitors in parallel mode (3-14 months)Module using the advantages of film capacitors a movement within the main loop of the bypass process using copper structure, copper thickness is assured of the main flow back to passing ability, low-temperature copper bar. Installation is simple, convenient, fast, efficient and greatly reduce the error probability. b the main circuit only requires two copper strips, instead of the past a large PCB, the product material costs and labor costs, and greatly reduced, reliability is improved. eliminating the need for PCB plug-in, Tin stove, welding and other processes. c part of the main loop control with separate driver, so strong electrical / weak separation to reduce the primary resonant circuit of the chip-driven part of the interference of the product after-sales maintenance and other convenient, reusable components, reducing maintenance costs . d As capacitors are modular forms package, available aluminum heat, movement can be hermetically sealed solved the fumes, moisture, cockroaches, dust and other metals into the movement’s internal problems, improved product reliability and life. e by a number of discrete capacitors in parallel to form a single module, to solve the discrete capacitor over the uneven flow, partial pressure of inequality and other issues, shorten the distance of the main circuit line, reducing the line inductance on the power distribution components of the impact.Actual use of the capacitor module To test the aluminum cooling module internal temperature the resonant capacitor, the capacitor module in the production of samples into an internal NTC thermistor. A customer to use 2 * 0.8?F/1600VDC modules used in the half-bridge circuit 15KW induction cooker.From the measured data showed that the resonant capacitor module in the aging room at 25 ? and 40 ?, full power about 45 minutes of work, film capacitor internal temperature to stabilize, and with the increased working hours, the temperature has been stable down. Current DC-LINK capacitor module (MKP-LA) and high resonant capacitor module (MKPH-RA) through a number of co-operation with mass use, the Division has been creating electronic format of the series capacitor modules successfully applied for national patents.Summary IGBT can be made by the form of modules form a single tube, cooling effect, over-current capability in this Division Reference IGBT internal cooling structure, developed the structure of the capacitor with aluminum cooling module, used in induction heating devices. After more than co-unit quantities for use, has a lot to promote the use of 2010. With the induction heating equipment market demand continues to increase, the product more competitive. Enterprises to improve their products, market share, must invest human and material resources, the old product updates, technology upgrades, in order to enhance their competitive forceRelated

How to design an optimal induction coil

Base details of High Frequency Induction Heating

waveform of DSP induction heaters

simulation of Faradays Law from University of Colorado Boulder

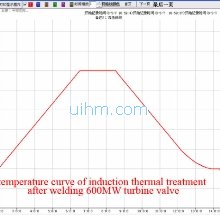

temperature curve of induction thermal treatment after welding 600MW turbine valve

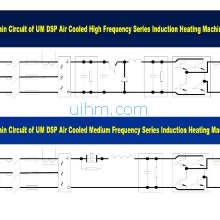

Main Circuit of UM DSP air cooled induction heaters

© Copyright 2025. uihm.com All Rights Reserved.

Newest Comment

No Comment

Post Comment