Heat Treating is the process of heating and cooling a steel to obtain desired properties.

Various types of heat treatment processes are used to change the following properties or conditions of the steel:

- Improve the toughness - Improve the machinability

-Increase the

hardness - Refine the grain structure

-Increase the

ductility - Remove the residual stresses

- Improve the wear resistance

Quenching

- The process of cooling austenite very rapidly or at a controlled rate to achieve a desired microstructure.

* The rapid cooling suppresses the formation of austenite to α + Fe3C

- Quenching of austenite produces martensite, which is used for applications that demand a hard material (e.g. knives, razor blades, surgery tools, cutting tools, etc).

- *

- When austenite + ferrite is quenched, all of the austenite transforms completely to martensite while the ferrite remains unchanged.

- *

- When austenite + cementite is quenched, again all of the austenite completely transforms into martensite while the cementite remains unchanged.

Figure: Quenching process.

1. Hardening

Hardening is the process of austenitizing a steel at a prescribed temperature, holding at that temperature for a length of time to ensure homogeneity in the austenite, and then quenching at a rate fast enough to prevent transformation to any product other than martensite.

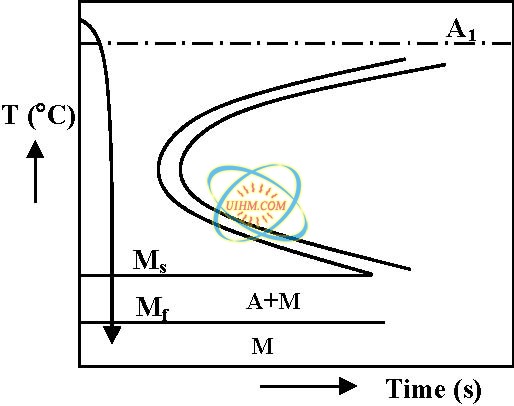

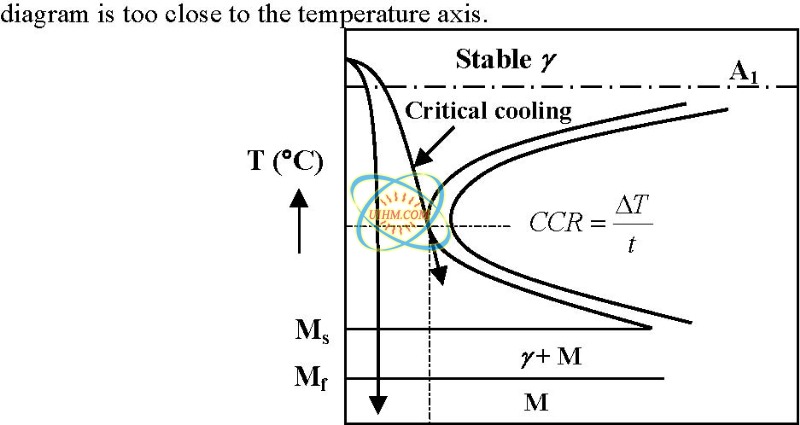

The cooling rate that just produces an entirely martensitic structure is the critical cooling rate (CCR). Therefore, this rate must be exceeded to ensure transformation of all the austenite to martensite.

* A range of quenchants can be used:

- Order of severity: 5% caustic soda, 5-10% brine, cold water, warm water, mineral oil, animal oil, vegetable oil

- Note: Quenching into oils may produce bainite rather than martensite

* Steels with less than 0.25 wt.%C cannot be hardened by quenching because the nose of the TTT

t

Time (s)

Time (s)

Quench Severity

Quenching effectiveness is substantially increased by agitation. Agitation of the part and/or the quenchant increases the rate of heat transfer between the quenchant and the surface of the part. The quench severity (H) is an indication of how effective a specific quenchant is. It correlates directly to the thermal stresses set up in the heat-treated part. Some typical values of H are:

| Quenchant | Quench Severity (H) | ||

|---|---|---|---|

| No Circulation | Mild Circulation | Violent Circulation | |

| Air | 0.02 | - | 0.25 |

| Oil | 0.25 | 0.35 | 0.95 |

| Water | 1.00 | 1.05 | 4.00 |

| Brine | 2.00 | 2.10 | 5.00 |

2. Tempering

- The process of re-heating the as-quenched (martensitic) steel to increase softness and ductility.

- *

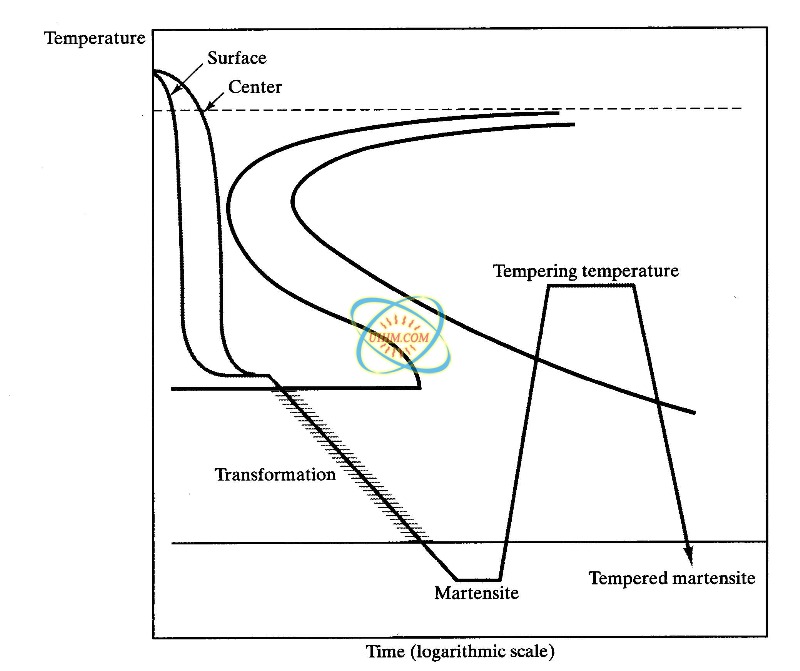

- Steel is heated above A1, quenched rapidly at a rate fast enough to miss the nose (or knee) of the TTT diagram to form martensite, and re-heated at a temperature below A1 to achieve the desired tempered hardness. Alloying elements generally slow down tempering.

- *

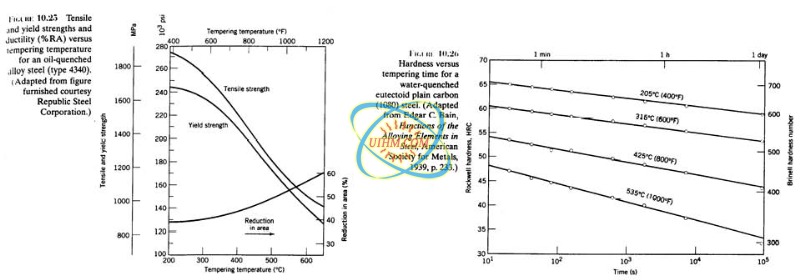

- When martensite is tempered above 250 °C, all martensite disappears and is replaced by ferrite and finely dispersed cementite.

Martensite (α') →α + Fe3C

Note: The new structure is not pearlite. It is called tempered martensite. To get back pearlite, you have to re-austenitize the steel and cool appropriately to obtain pearlite.

* When a steel is kept at a temperature between 400 °C and 727 °C for a long period of time (> 24 hours), the carbide balls up forming what is called spheroidized carbide.

Figure: Quenching and tempering process for a plain-carbon steel.

Effect of Tempering on Mechanical Properties of Steels

- *

- Improves toughness

- *

- Increases ductility

- *

- Reduces hardness (softens the steel)

3. Martempering (Marquenching)

- Quenching procedure used primarily to minimize distortion and cracking of heat-treated steels

- Consists of the following steps:

- (1)

- Austenitize the steel at the appropriate temperature

- (2)

-

Quench to a

temperature just above the Ms (usually,

into

an oil or molten salt bath)

- (3)

-

Hold in the

quenchant to obtain uniform

temperature

throughout the steel

- (4)

-

Cool at a moderate

rate through the martensite

transformation region.

Schematic of a typical martempering process.

Mechanical properties of 1095 steel heat-treated by martempering and conventional quenching.

| Heat Treatment | Hardness (HRC) | Impact (ft-lb) | Elongation in 1in (%) |

|---|---|---|---|

| Water quench and temper | 53.0 | 12 | 0 |

| Martemper and temper | 53.0 | 28 | 0 |

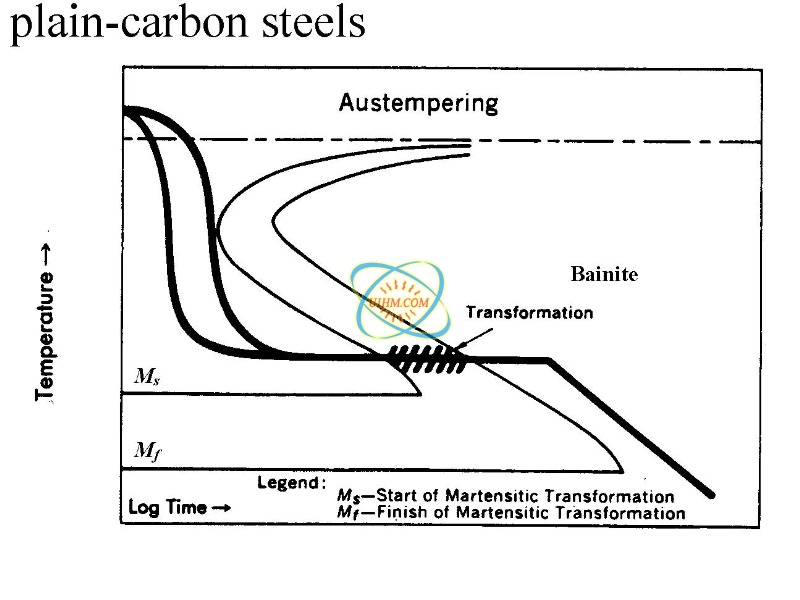

4. Austempering

- -

-

An isothermal

heat treatment designed to produce bainite in plain-carbon steels

- -

-

An alternative

procedure to quenching and tempering

- *

- improves strength and toughness

- *

- decreases cracking and distortion

- *

- but takes a long time to complete

-Consists of the following steps:

- (1)

- Austenitize the steel at the appropriate temperature

- (2)

- Quench to a temperature just above the Ms

- (3)

-

Hold isothermally

in the quenchant until γ→ bainite

transformation is complete

- (4)

- Cool to room temperature in air

Mechanical properties of 1095 steel heat-treated by austempering and conventional quenching.

| Heat Treatment | Hardness (HRC) | Impact (ft-lb) | Elongation in 1in (%) |

|---|---|---|---|

| Austemper | 52.0 | 45 | 11 |

| Water quench and temper | 53.0 | 12 | 0 |

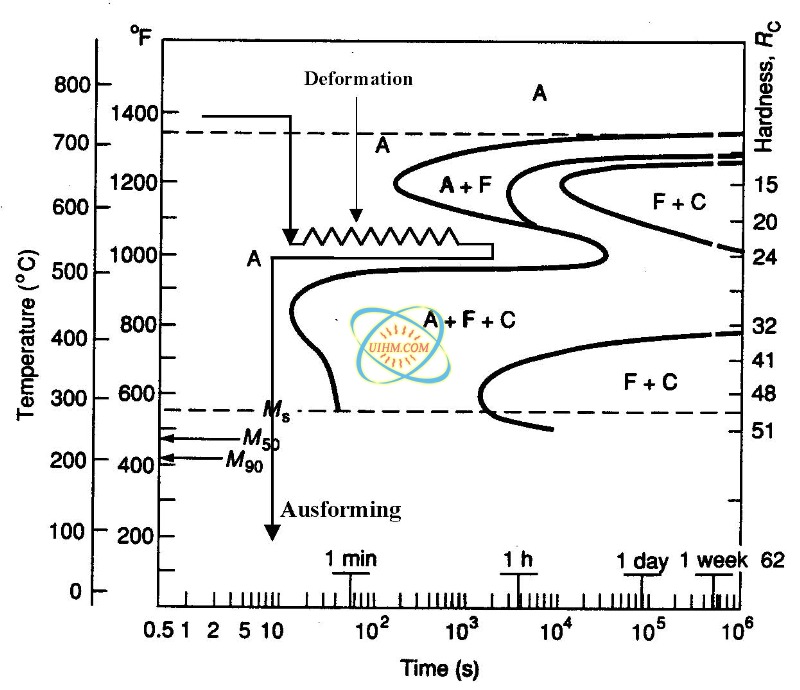

5. Ausforming

Ausforming (also known as low-temperature thermomechanical treatment (LTMT)), involves the deformation of austenite in the metastable bay between the ferrite and bainite curves of the TTT diagram. After deformation, the steel is cooled rapidly to form martensite. The combined effect of austenite deformation and high dislocation density gives a very fine martensite microstructure with high yield strength and high toughness.

Alloying elements that promote the development of a separate bainite nose in TTT diagrams include chromium, molybdenum, nickel, tungsten, and manganese.

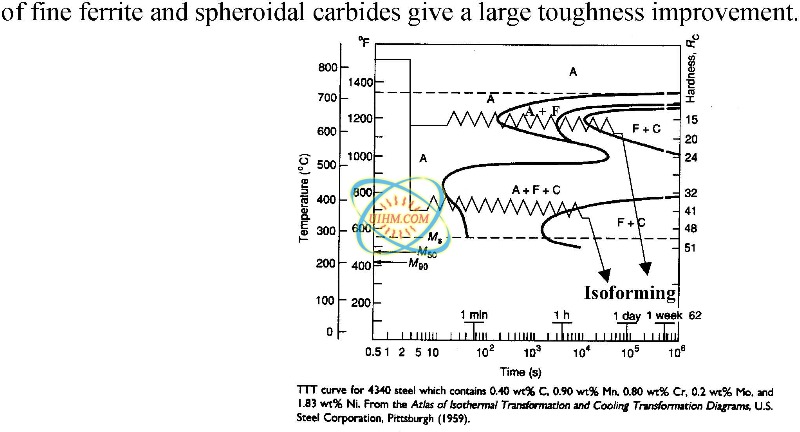

6. Isoforming

This is similar to ausforming, but here the deformation of austenite is continued at the temperature where austenite transforms to ferrite and iron carbide. Martensite is not formed. The microstructure

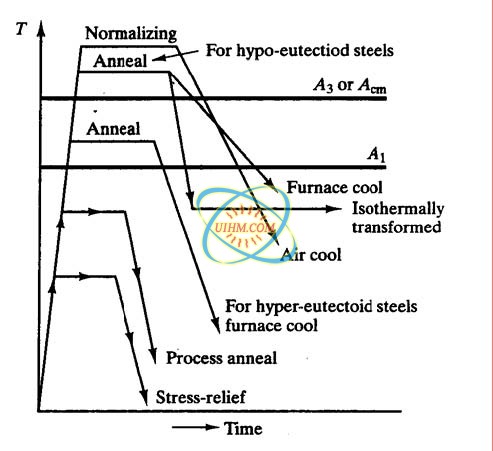

7. Annealing

Annealing is simply the process of heating steels to and holding at some specified elevated temperature and cooling fairly slowly.

In practice, annealing operation consists of three steps:

- (1)

- Heat the steel to a specified temperature

- (2)

- Soak it at this temperature for a time sufficient to allow the necessary changes to occur

- (3)

- Cool at a predetermined rate in the furnace

- *

-

The major purpose

of annealing is to:

- Soften the steel and to improve machinability.

- Relieve internal stresses induced by some previous treatment (rolling, forging, uneven cooling).

- Produce a specific microstructure.

- *

- Annealing is applied to forgings, cold-worked sheets and wires, welded parts, and castings.

- *

- The three main annealing processes that are used for steels are:

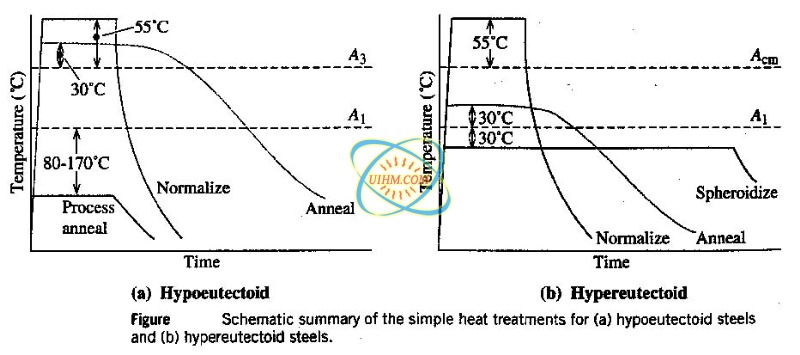

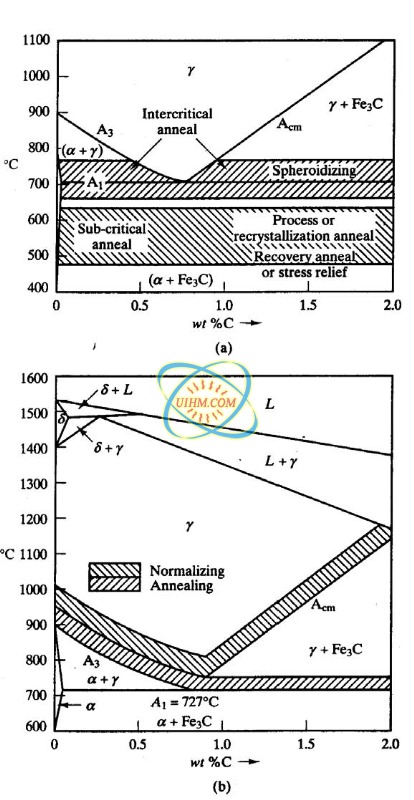

1. Subcritical annealing - is carried out below A1. No austenite transformation is involved. The main aim is to relieve residual stresses caused by previous processing such as coldworking, welding, or casting (stress relief anneal) or to recrystallize cold-worked material (process anneal).

- *

- Commonly employed for wires and sheets

- *

- Carried out at about 500° to 690 °C for several hours

* Process anneal is carried out at higher temperatures (usually 11° to 22 °C below A1) than stress relief anneal (usually about 500° to 650 °C).

2. Intercritical annealing -is carried out between A1 and A3 for hypoeutectoid steels or between A1 and Acm for hypereutectoid steels.

* Steel is heated to within 55 °C above A1 and then transformed at a temperature less than 55 °C below A1 to produce a structure consisting of spheroidized carbide particles in a ferrite matrix.

- The spheroidized structure (spheroidite) has the minimum hardness, the maximum ductility, as well as the maximum machinability.

3. Supercritical or Full annealing -is carried out above A3 for hypoeutectoid steels and between A1 and Acm for hypereutectoid steels.

8. Normalizing

Consists of three steps:

- Heat the steel to a temperature above the upper critical temperature (A3 or Acm)

- Hold at the temperature for a period of time, and

- Air-cool at room temperature

Note: The air cooling may be natural or slightly forced air convection. Typical normalizing temperatures are as follow:

- (i)

- 55 °C (100 °F) above A3 for hypoeutectoid steels.

- (ii)

- 27 °C (50 °F) above Acm for hypereutectoid steels.

Benefits of Normalizing include:

- improved machinability

- grain size refinement

- homogenization of composition

- modification of residual stresses

Figure: Heating and cooling cycles for stress relief, process anneal, normalizing and full annealing of hypo- and hypereutectoid steels.

Figure: (a) Temperature ranges for subcritical annealing (stress relief and recrystallization anneal) and intercritical annealing (spheroidizing). (b) Temperature ranges for normalizing and full annealing of steels.