Objective: Anneal a brazing wire for preform production.

Material :Copper Nickel Silver 2774 Alloy rod 0.070″ (1.8mm) diameter.

Temperature 650ºF(343.3ºC)

Frequency 281 kHz

Equipment • UM-06A-UHF induction heating system equipped with a remote workhead with one 1.0 μF capacitor, and a 4-20mA input controller to aid in voltage ramping.

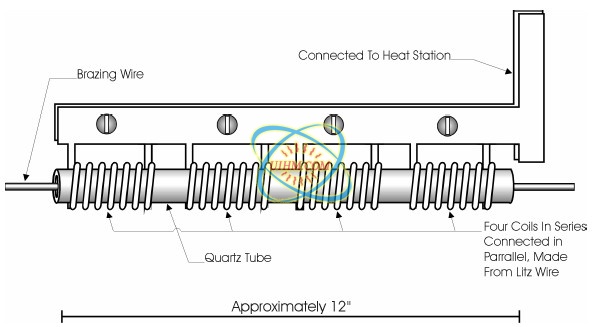

• An induction heating coil designed and developed specifically for this application.

Process A unique helical coil consisting of four consecutive coils connected in parallel with a quartz tube lining is used to heat the wire to 650ºF (343.3ºC) for annealing.

Results/Benefits Induction heating provides:

• Higher productivity of 27’ (8.2m) per minute

• Reduction in surface oxidation & scaling

• Consistent, repeatable results

Newest Comment

No Comment

Post Comment