Objective Annealing the end of a steel hydraulic motor shaft prior to machining

Material .75” (19mm) diameter steel rod, 6” (152.4mm) long with a keyway at the end

Temperature 1350 ºF (732 ºC)

Frequency 359 kHz

Equipment • UM-06A-UHF induction heating system, equipped with a remote workhead containing one 1.0 μF capacitor

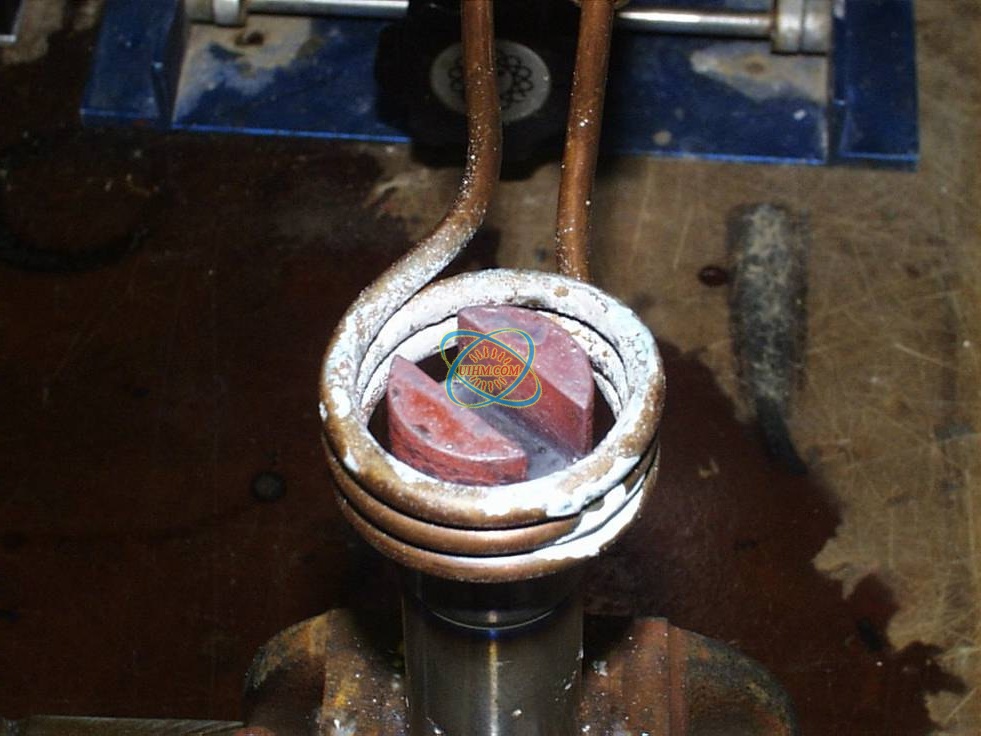

• An induction heating coil designed and developed specifically for this application.

Process A three turn helical coil is used for annealing the motor shaft.

The end of the motor shaft is placed in the coil and power is applied for 20 seconds to reach 1350 ºF (732 ºC) and turn the steel red hot

Results/Benefits Induction heating provides:

• High efficiency, low energy cost

• Precise and controllable placement of heat to anneal only the required area

• Faster production process

• Consistent results

Material .75” (19mm) diameter steel rod, 6” (152.4mm) long with a keyway at the end

Temperature 1350 ºF (732 ºC)

Frequency 359 kHz

Equipment • UM-06A-UHF induction heating system, equipped with a remote workhead containing one 1.0 μF capacitor

• An induction heating coil designed and developed specifically for this application.

Process A three turn helical coil is used for annealing the motor shaft.

The end of the motor shaft is placed in the coil and power is applied for 20 seconds to reach 1350 ºF (732 ºC) and turn the steel red hot

Results/Benefits Induction heating provides:

• High efficiency, low energy cost

• Precise and controllable placement of heat to anneal only the required area

• Faster production process

• Consistent results

annealing-motor-shaft

Newest Comment

No Comment

Post Comment