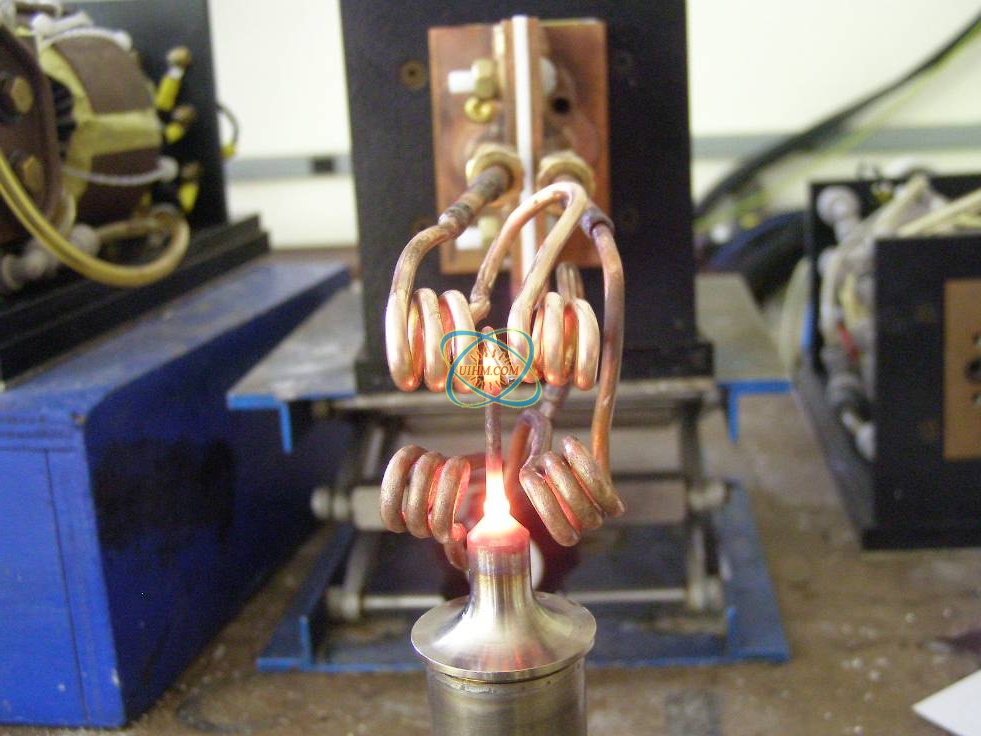

Objective Simultaneously braze two positions on a stainless steel manifold

Material Stainless steel manifold 4” (101.6mm) long, 1” (25.4mm) in diameter and nico braze

Temperature 1800 ºF (982 ºC)

Frequency 198 kHz

Equipment • Power of 20kW induction heating system, equipped with a remote workhead containing one 1.0μF capacitor.

• An induction heating coil designed and developed specifically for this application.

Process A dual six turn split helical coil is used to simultaneously braze the manifold. The manifold is placed in the coil and power is applied for 20 seconds to flow the braze and create the joint.

Results/Benefits Induction heating provides:

• Creates a liquid and gas-tight braze that can withstand shock and vibration

• Precise placement of heat

• Energy efficient

• Hands-free heating that involves no operator skill for manufacturing

Material Stainless steel manifold 4” (101.6mm) long, 1” (25.4mm) in diameter and nico braze

Temperature 1800 ºF (982 ºC)

Frequency 198 kHz

Equipment • Power of 20kW induction heating system, equipped with a remote workhead containing one 1.0μF capacitor.

• An induction heating coil designed and developed specifically for this application.

Process A dual six turn split helical coil is used to simultaneously braze the manifold. The manifold is placed in the coil and power is applied for 20 seconds to flow the braze and create the joint.

Results/Benefits Induction heating provides:

• Creates a liquid and gas-tight braze that can withstand shock and vibration

• Precise placement of heat

• Energy efficient

• Hands-free heating that involves no operator skill for manufacturing

brazing-two-positions

Newest Comment

No Comment

Post Comment