Objective: induction Curing Adhesive for the internal wall (inner interface) of a steel motor shaft to bond electronic stress/strain gauges into place.

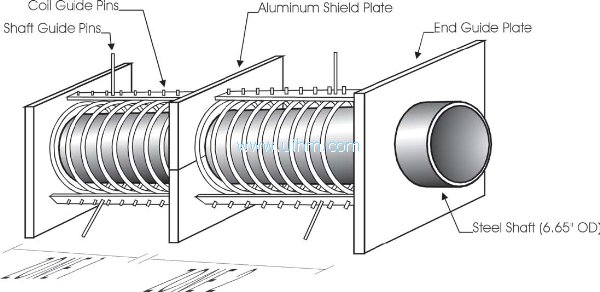

Material: Steel shaft measuring 6.65" (168.9mm) OD, 5.5"(139.7mm) ID and 70" (1.8m) long. Aluminum shield plate and two end guide plates.

Temperature: 285°F(140.6°C) > 300°F(148.9°C)

Frequency: 60 kHz Equipment

• UM-60AB-RF induction heating system equipped with a remote workhead enclosure for double capacitor/buss modules. Zone 1 needs a 0.25 μF capacitor, while Zone 2 requires 0.66 μF

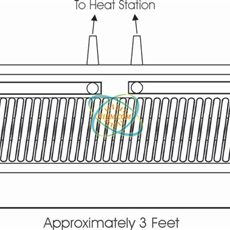

• An induction heating coil designed and developed specifically (half open) for this application.

Process: A complex two coil system, shield and stud systems used to provide proper axial alignments of the shaft & coil while allowing the fixture to be open for removal of the shaft.

The aluminum shield separates the two required heat zones. An average temperature of 290ºF(143.3ºC) is maintained for 1.5 hours.

Results/Benefits: Induction heating provide:

• Precise, accurate control of heat placement

• Minimized coating defects

• Repeatable results

Newest Comment

Post Comment