Objective To heat inconel billets to 2050°F (1121.1ºC) for a forging process.

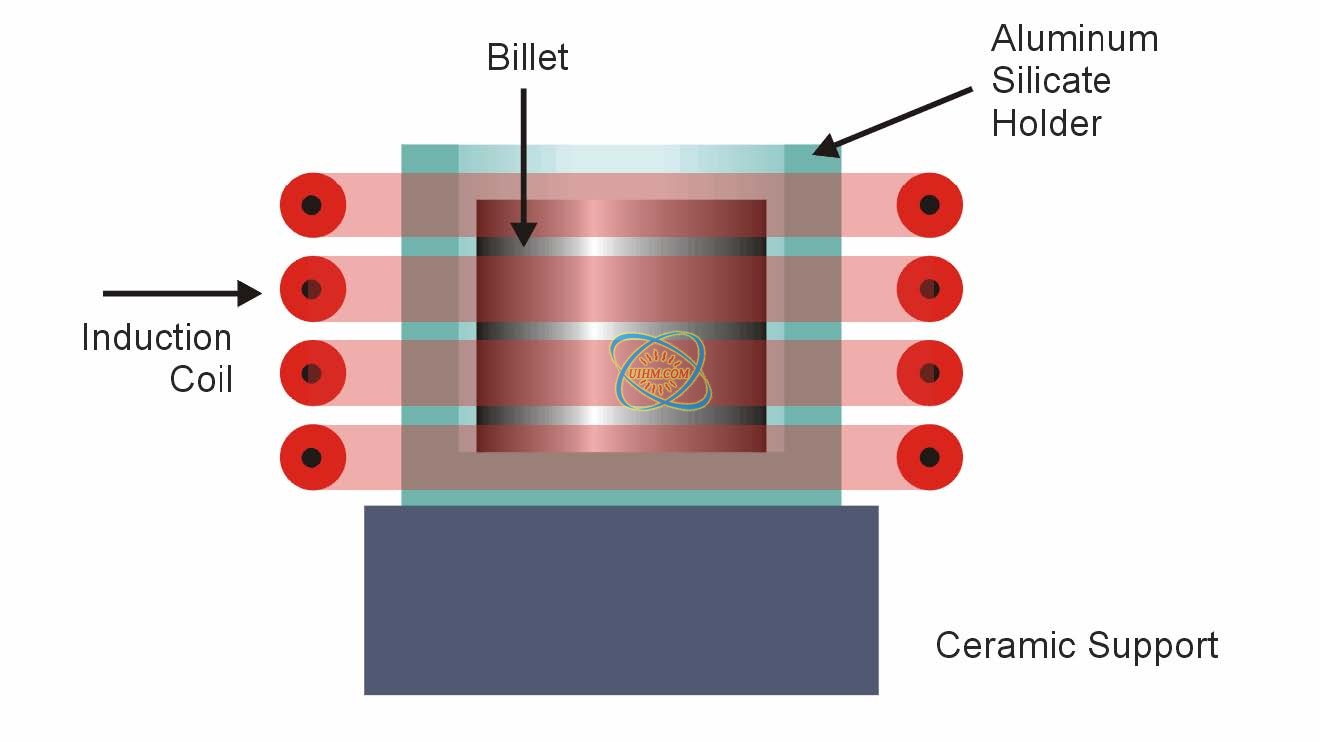

Material Small inconel billets 0.39” OD, 0.7” length (.99mm OD, 17.8mm length) with ceramic crucible 1.0” OD, 0.7” ID, 1.4” length (25.4mm OD, 17.8mm ID, 35.6mm length); large inconel billets 0.5” OD, 1.0” length (12.7mm OD, 25.4mm length) with ceramic crucible 1.25” OD, 0.87” ID, 1.37” length (31.8mm OD, 22.1mm ID, 34.8mm length)

Temperature 2050°F (1121.1ºC)

Frequency 226 kHz

Equipment • Power of 20kW induction heating system equipped with a remote workhead.

• An induction heating coil designed and developed

specifically for this application.

Process A four-turn helical coil is used to deliver uniform heat to the inconel billets. Both size billets heat to 2050°F (1121.1ºC) within 12 seconds.

Results/Benefits Induction heating provides:

• Uniform and repeatable results

• Flameless

Forging Inconel Billets

Newest Comment

No Comment

Post Comment