In recent years, gear manufacturers have gained additional knowledge about how technology can be used to produce quality parts. The application of this knowledge has resulted in gears that are quieter, lighter, and lower cost, and have an increased load-carrying capacity to handle higher speeds and torques while generating a minimum amount of heat.

Gear performance characteristics (including load condition and operating environment) dictate the required surface hardness, core hardness, hardness profile, residual stress distribution,grade of steel, and the prior microstructure of the steel 1.

In contrast to carburizing and nitriding, induction hardening does not require heating the whole gear

Another goal of induction gear hardening is to produce significant compressive residual stresses at the surface and in a subsurface region1. Compressive stresses help inhibit crack development and resist tensile bending fatigue. Depending upon the required hardness pattern and tooth geometry, gears are induction hardened by encircling the part with a coil (so-called “spin hardening”) or, for larger gears, heating them “tooth-by-tooth” (“tip-by-tip” or “gap-by-gap”).

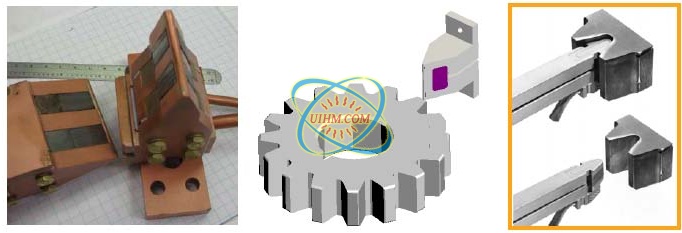

“Gap-by-Gap” induction hardening of gears

“Gap-by-Gap” gear hardening principle and typical inductor designs

“Gap-by-Gap” technique requires the coil to be symmetrically located between two flanks of two adjacent teeth ( Hardening inductor can be designed to heat only the root and/or flange of the tooth, leaving the tip and tooth core soft, tough and ductile .

gear1

Newest Comment

No Comment

Post Comment