Objective To harden the perimeter of ¼” thick steel cam assemblies

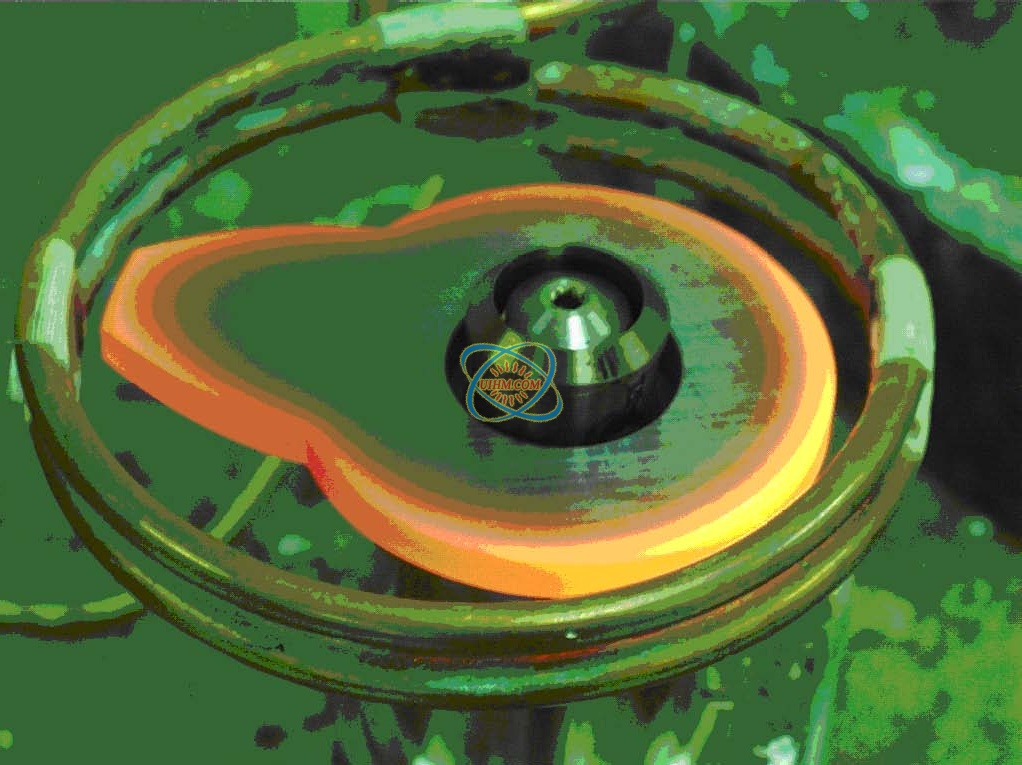

Material ¼” thick steel cam assemblies of varying geometries

Temperature 1650 ºF (900 °C)

Frequency 177 kHz

Equipment Power of 20 kW, induction heating system, equipped with a remote heat station containing one 1.0μF capacitor and an induction heating coil designed and developed specifically for this application

Process A two-turn helical coil is used to heat the cams. The heat time varies from 120-150 seconds. After heating, the parts are quenched in water.

Results/Benefits Hardening the cam outer surfaces with induction results in:

• uniform heating for uniform results

• one coil can be used for many geometries

• consistent results from piece to piece

Related

© Copyright 2025. uihm.com All Rights Reserved.

Newest Comment

No Comment

Post Comment