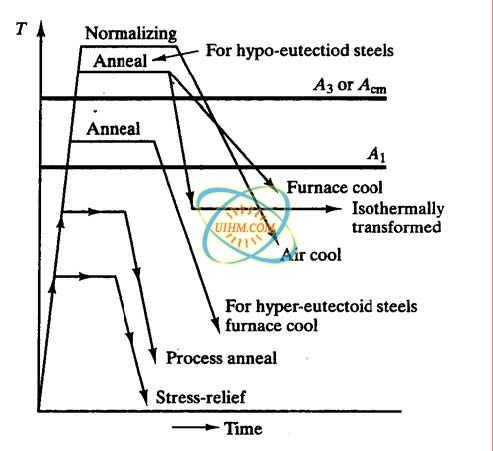

Heat Treating is the process of heating and cooling a steel to obtain desired properties.

Various types of heat treatment processes are used to change the following properties or conditions

of the steel:

- Improve the toughness – Improve the machinability

- Increase the hardness – Refine the grain structure

- Increase the ductility – Remove the residual stresses

- Improve the wear resistance

Quenching

- The process of cooling austenite very rapidly or at a controlled rate to achieve a desired

microstructure.

* The rapid cooling suppresses the formation of austenite to α + Fe3C

- Quenching of austenite produces martensite, which is used for applications that demand a hard

material (e.g. knives, razor blades, surgery tools, cutting tools, etc).

* When austenite + ferrite is quenched, all of the austenite transforms completely to

martensite while the ferrite remains unchanged.

* When austenite + cementite is quenched, again all of the austenite completely transforms

into martensite while the cementite remains unchanged.

1. Hardening

Hardening is the process of austenitizing a steel at a prescribed temperature, holding at that

temperature for a length of time to ensure homogeneity in the austenite, and then quenching at a

rate fast enough to prevent transformation to any product other than martensite.

The cooling rate that just produces an entirely martensitic structure is the critical cooling rate

(CCR). Therefore, this rate must be exceeded to ensure transformation of all the austenite to

martensite.

* A range of quenchants can be used:

- Order of severity: 5% caustic soda, 5-10% brine, cold water, warm water, mineral oil,

animal oil, vegetable oil

- Note: Quenching into oils may produce bainite rather than martensite

* Steels with less than 0.25 wt.%C cannot be hardened by quenching because the nose of the TTT

diagram is too close to the temperature axis.

Quench Severity

Quenching effectiveness is substantially increased by agitation. Agitation of the part and/or the

quenchant increases the rate of heat transfer between the quenchant and the surface of the part. The

quench severity (H) is an indication of how effective a specific quenchant is. It correlates directly to

the thermal stresses set up in the heat-treated part. Some typical values of H are:

2. Tempering

- The process of re-heating the as-quenched (martensitic) steel to increase softness and ductility.

* Steel is heated above A1, quenched rapidly at a rate fast enough to miss the nose (or knee)

of the TTT diagram to form martensite, and re-heated at a temperature below A1 to achieve

the desired tempered hardness. Alloying elements generally slow down tempering.

* When martensite is tempered above 250 °C, all martensite disappears and is replaced by

ferrite and finely dispersed cementite.

Newest Comment

No Comment

Post Comment