The induction heating of round bars and round-corner-square (RCS) billets are often treated as equivalent applications, even though they are not. This article reconciles recent theoretical and practical achievements in providing required heat uniformity when inductively heating rectangular and trapezoidal workpieces.

The induction heating of round bars and round-corner-square (RCS) billets are often treated as equivalent applications, even though they are not. This article reconciles recent theoretical and practical achievements in providing required heat uniformity when inductively heating rectangular and trapezoidal workpieces.

induction heating, very popular in the heating of cylindrical workpieces, is also commonly used to heat rectangular billets. Workpieces of this general shape include billets, bars, blooms and slabs, which will be referred to in this article for temperature uniformity within the transverse cross section of the RCS billets, including edges. There are, nonetheless, some misunder- standings among those who use induction heating regarding its abil- ity to provide the required temperature uniformity within RCSbillets and factors affectingthermal profileswithin a workpiece.

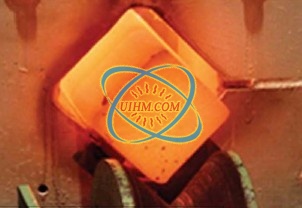

as RCS (round-corner-square) billets (Figure 1). In the heating of any shape, it is typically required to not only raise the billet’s temperature to a specified level but to also achieve a certain degree of heat uniformity throughout the part. The uniformity specifications may include maximum tolerable thermal gradients: surface-to-core, end-to-end and side-to-side. A billet that is heated non-uniformly can negatively affect the quality of heated products and cause problems for hot-forming machinery.

As a consequence of the non-cylindrical geometry of RCS billets, customers often specify the temperature uniformity in their trans- verse cross section, including the maximum allowable “central part- to-corner” temperature non-uniformity. Depending upon the specific induction-heating parameters used, the edge areas of RCS billets can be under heated, overheated and heated uniformly.

Related

© Copyright 2025. uihm.com All Rights Reserved.

Newest Comment

No Comment

Post Comment