Objective: To heat selected areas of a glass lined steel tank to 16000F in order to perform repairs of cracks and chips. The glass is used as a frit which must be reflowed and filled into the damaged areas. Temperature control is crucial due to the flow characteristics of glass. Crazing and cracking can result if heating and cooling occur too quickly or too slowly.

Material: Steel tank lined with glass measuring 34″ in diameter and 1″ thick. Wet ground frit solution Wet and dry cover coat frits.

Temperature: 16000F

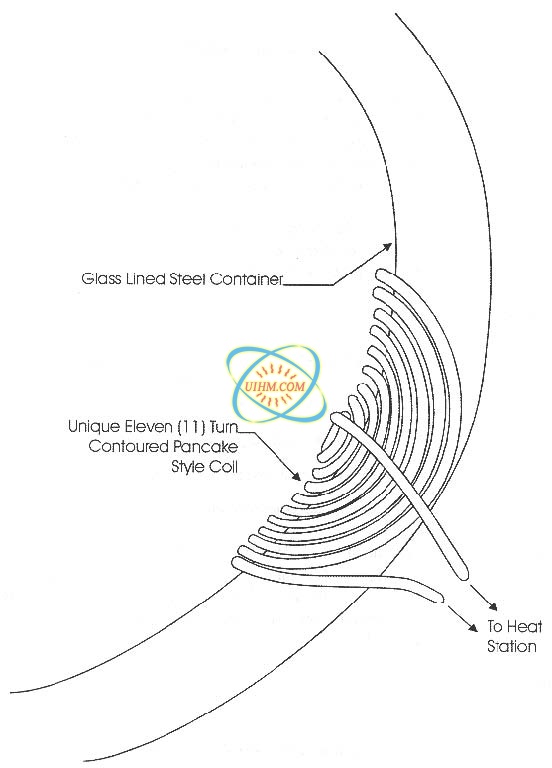

Application: The Power of 25KW,25KW output solid state induction power supply along with a unique eleven (11) turn pancake style coil were utilized to achieve the following results:

# 16000F was reached in just over 15 minutes.

# A slow heat ramp was used to optimize the glass flow.

# A quality surface resulted after the proper heat cycle was established.

Equipment: Power of 25KW,25KW output solid state induction power supply including one (1) remote heat station containing eight (8) capacitors totaling 0.66 µF, and a unique eleven (11) turn pancake style coil manufactured from 3/16″ copper tubing formed to the curve of the tanks wall.

Frequency: 84 kHz

Repair Glass Lined Steel Tank

Newest Comment

No Comment

Post Comment