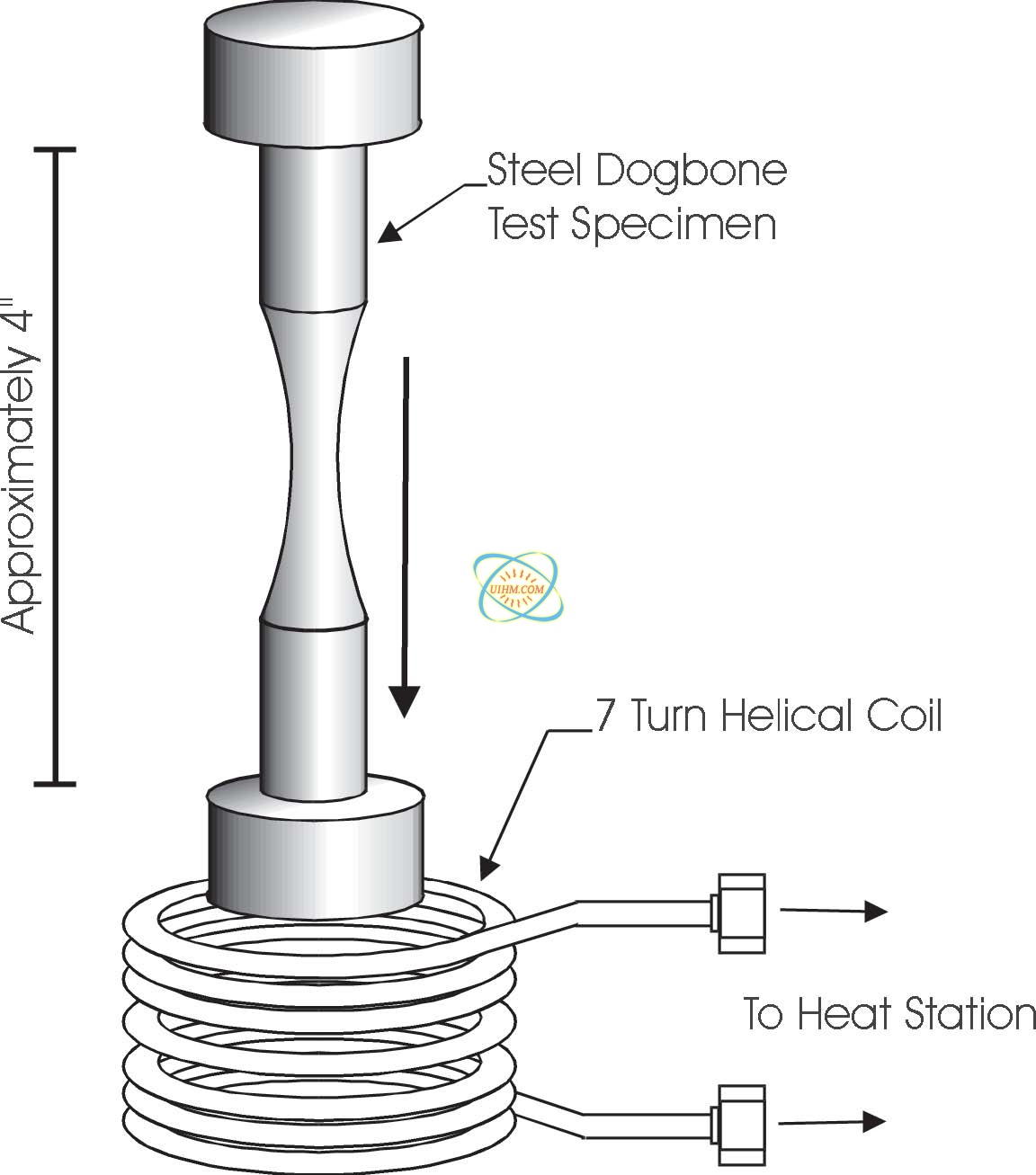

Objective: To heat a magnetic steel dogbone specimen to 12000F as quickly as possible and sustained for tensile testing. Heating should take place using a helical coil placed square in relation to the long axis of the gage area. Also, thermal and mechanical loading need to be controlled through the use of a temperature sensor output.

Material: 1008 Steel Dogbone Test Specimen measuring 4 3/4″ long, 11/16″ in diameter at the ends, and 0.406″ in diameter in the middle of the gage section.

Temperature: 12000F

Application: The UIHM Laboratory Staff chose to use the Power of 15KW,15KW output solid state induction power supply along with a seven (7) turn helical coil, a Mirage Infrared Thermometer, and a 4-20 mA input device for enhanced voltage ramp to achieve the following results:

# 12000F was reached throughout the gage area in 6.1 seconds.

# Temperature was sustained using the closed loop system provided by the Mirage Infrared Thermometer.

# Even and uniform heating was achieved through the use of the seven (7) turn helical coil.

Equipment: Power of 15KW,15kW output solid state induction power supply including one (1) remote heat station containing two (2) capacitors totaling 0.66 µF, a seven (7) turn helical coil with a 1 1/4″ ID and measuring 1 1/2″ OAL, a 4-20 mA output device to facilitate voltage ramping, and an optical thermometer.

Frequency: 231 kHz

Heating Dogbone Specimen

Newest Comment

No Comment

Post Comment