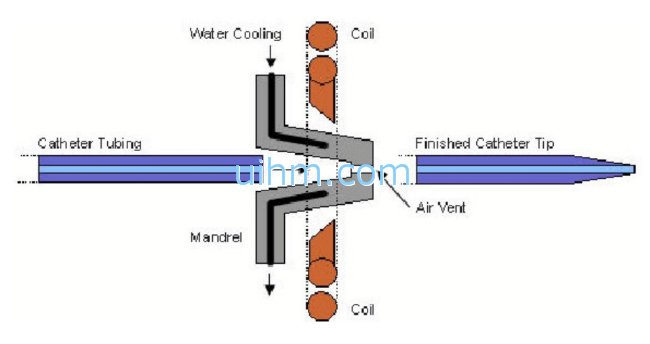

Objective Water-cooled brass mandrel die, nylon LDPE catheter, “K” type thermocouple and temperature controller.

Material materials, supplies involved in the application

Temperature 400°F (204°C)

Frequency 325kHz

Equipment 14KW induction heating system, remote heat station containing one 0.66 microfarad capacitor.

Process A two turn plate concentrator coil is used to heat the die. To measure the temperature on the ID and establish the time-totemperature relationship, the thermocouple is inserted inside the brass die. RF power is applied for 3 seconds to heat the die to 400°F (204°C). The nylon tube is pushed into the die and formed into a catheter.

Results/Benefits Induction heating provides:

• Increased throughput and reduced cycle time

• Consistent and repeatable results

• Clean heating

• Precise temperature control

Induction Heating catheter tipping die

Newest Comment

No Comment

Post Comment