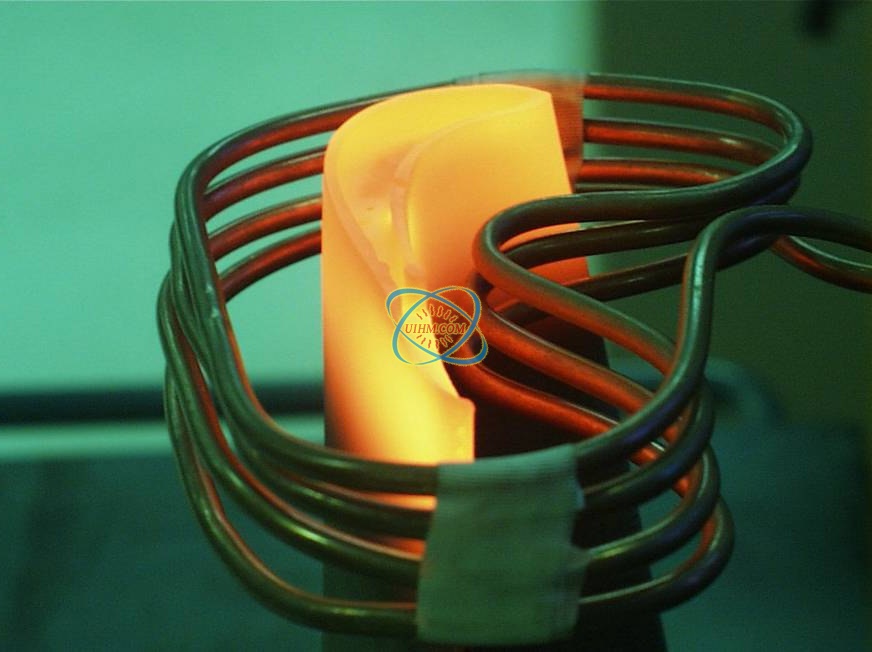

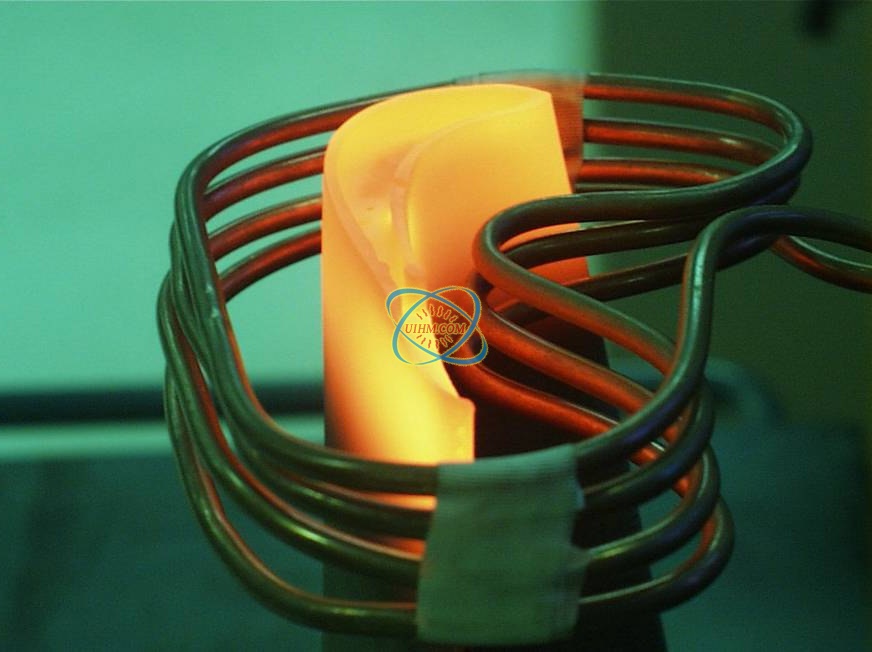

Objective To uniformly heat jet engine turbine fan blades to 1800°F (982.2ºC) within five minutes for a welding application

Material Jet engine turbine fan blades with 2”(50.8mm) length tip

Temperature 1800°F (982.2ºC)

Frequency 216 kHz

Equipment • Power of 6kW induction heating system equipped with a remote workhead.

• An induction heating coil designed and developed specifically for this application.

Process A four-turn helical coil with a kidney shape is used to provide uniform heat for this application. The turbine blade is placed inside the coil and power is applied for 5 minutes until the top

0.25” (6.35mm) of the blade reaches 1800°F (982.2ºC). An optical pyrometer is used to measure the temperature of the

part.

Results/Benefits Induction heating provides:

• Even and consistent distribution of heat

• Faster production rate

• Reduces product waste through rapid heat-up and cool down cycles

Heating fan blades for welding

Newest Comment

No Comment

Post Comment