Objective

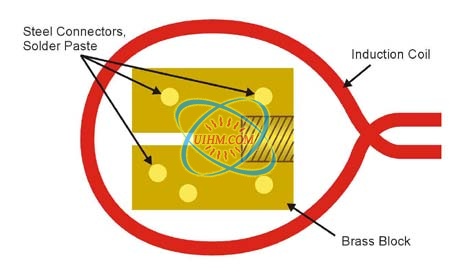

Heat an assembly of small, gold-plated steel connectors to a brass block.

Approx. 1/8” (3.2mm) diameter gold-plated steel connectors,

1”(25.4mm) square x 1/4” thick brass block ,600°F(315.6ºC),240 kHz

Temperature,Frequency,Equipment

6 kW induction heating system equipped with aremote workhead.

An induction heating coil designed and developed specifically for this application.

Process

A two-turn helical coil is used to provide uniform heat to parts

assembly. Solder paste and flux are applied to the joint area and power is applied for 20 seconds to solder the parts. Proper fixturing is needed to hold the parts in position.

Related

induction brass soldering radiator (heat sink)_2

This illustration shows how the connecting sleeve of a plate heat exchanger is inductively brazed on

UHF handheld induction heater for brazing copper

UHF handheld induction heater for brazing brass

handheld induction coil for soldering brass

handheld induction coil for brazing brass

© Copyright 2025. uihm.com All Rights Reserved.

Newest Comment

No Comment

Post Comment