1 high-frequency welding

1.1 principle: the principle of electromagnetic effects in the alternating magnetic field

Metal inside the material rapidly induced significant vortex

Induction heating equipment.

1.2 Advantages: energy saving, and no high-voltage electric shock hazard, fast heating, volume

Small size, light weight, easy to install.

Disadvantages: power is not easy to control (vehicle positioning requires high).

1.3 Application examples:

High-frequency welding industry applications:

★ diamond tools, carbide cutting tools, welding;

★ all kinds of metal steel - steel, steel - copper, copper - copper equivalent metal or different

Kinds of metal high-frequency welding;

★ metal material hardening, annealing, quenching and tempering, tempering and other heat treatment;

★ metal hot forging, heat molding;

★ powder metallurgy sintering and metal smelting;

★ other field that need to be heated to metal;

★ organic coating curing;

★ of monocrystalline's heating stretch;

1.1 principle: the principle of electromagnetic effects in the alternating magnetic field

Metal inside the material rapidly induced significant vortex

Induction heating equipment.

1.2 Advantages: energy saving, and no high-voltage electric shock hazard, fast heating, volume

Small size, light weight, easy to install.

Disadvantages: power is not easy to control (vehicle positioning requires high).

1.3 Application examples:

High-frequency welding industry applications:

★ diamond tools, carbide cutting tools, welding;

★ all kinds of metal steel - steel, steel - copper, copper - copper equivalent metal or different

Kinds of metal high-frequency welding;

★ metal material hardening, annealing, quenching and tempering, tempering and other heat treatment;

★ metal hot forging, heat molding;

★ powder metallurgy sintering and metal smelting;

★ other field that need to be heated to metal;

★ organic coating curing;

★ of monocrystalline's heating stretch;

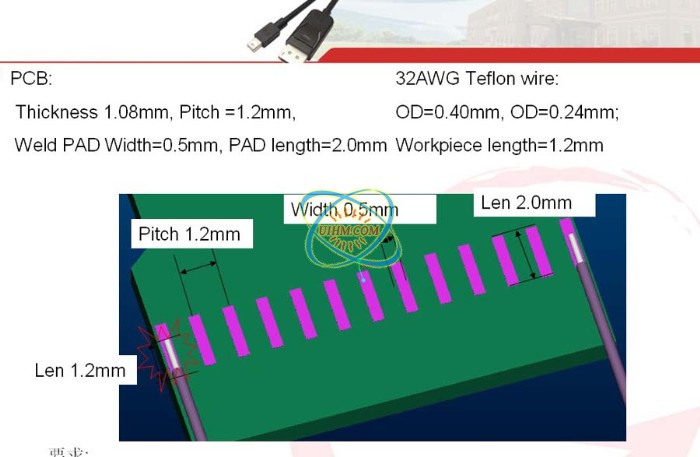

hdmi welding

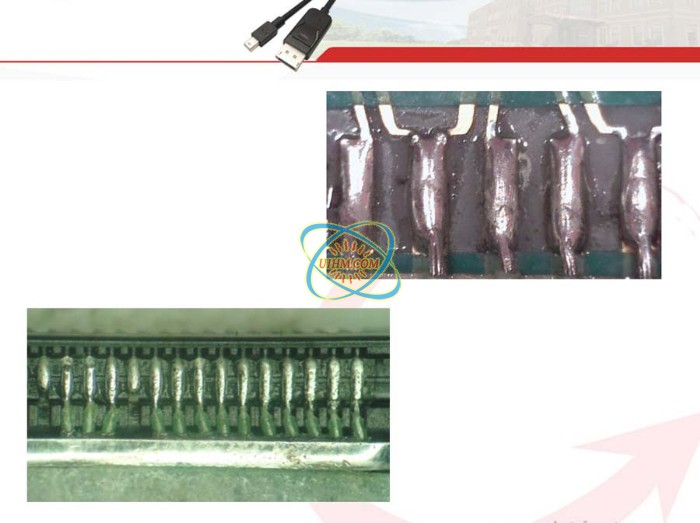

hdmi welding result

Newest Comment

No Comment

Post Comment