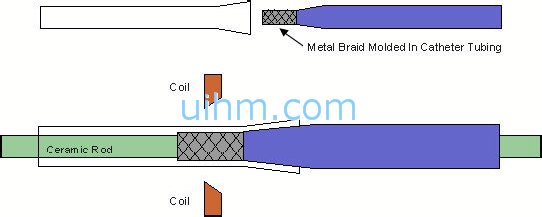

Objective Heat a metal braid in a plastic catheter tube to 250°F (121.1ºC) so that another catheter tube can be bonded to it.

Material 0.05” (1.27mm)diameter catheter tubes, some with a metal braid, ceramic rod

Temperature 250°F(121.1ºC)

Frequency 306kHz

Equipment 6KW induction heating system equipped with a remote workhead with one 1.2 μF capacitor

• An induction heating coil designed and developed specifically for this application.

Process A single turn helical coil is used to heat the metal braid for plastic reflow. To maintain the correct inside diameter of the tubing. A ceramic rod is inserted through the tubing. Heat is applied for 3.5 seconds to reach 250°F (121.1ºC). The metal braid melts the plastic and creates a bond.

Results/Benefits Induction heating provides:

• Controlled rapid application of heat

• Consistent, repeatable results

• Energy efficient

Newest Comment

No Comment

Post Comment