Technology High Frequency & Rapid Tuning Introduction The purpose of this Tech Note is to demonstrate the advantages of UIHM’s new satellite Star technology for precision induction heating applications. In each section, we will show how a particular aspect of this new technology makes a crucial difference in running a specific process or application successfully. UIHM was the first Chinese manufacturer to introduce all solid state induction heating RF power supply technology in 1986, and we have pioneered its use in a diverse range of processes. Today, UIHM systems are known worldwide for their speed, reliability and consistency. Our new satellite Star technology advances the industry standard for induction heating performance to a new level of costeffective precision.Among the many advantages of the new technology, this document will focus on six: rapid digital tuning, advanced microprocessor control, high frequency operation and closed loop temperature control, as well as the RS-485 interface and flexible remote heat station which are standard with every satellite Star power supply.

In the first section, satellite Star’s rapid

digital tuning and high frequency

operating range produce faster

throughput and increased production rates in an annealing process for copper crimp connectors. Next, the new technology’s high frequency operation allows induction heating to be used for brazing miniature diamond tips on cutting tools. The satellite Star standard RS-485 interface allows the user to download process data into a computer for statistical process control. The epoxy curing process described in the third section illustrates the benefits of this feature. The next section shows how the satellite Star remote heat station, which can be located up to 200 ft. away from the power supply, offers significant advantages for a conveyor line manufacturing operation. Finally, the fifth section illustrates how closed loop temperature control improves a tempering process for steel punches. High Frequency and Rapid Tuning Improve Annealing Process For Copper Crimp Connectors

The Problem

Existing induction heating processes for

annealing copper crimp connectors often

produce inconsistent results and

unsatisfactory yield. In this section we will

show how the satellite Star’s high frequency

operating range and rapid digital tuning

combine to increase throughput and improve consistency for this type of process. Crimping is the metallurgical compression of a terminal around the conductor of a wire to create a common electrical path of low resistance and high current carrying capability. This technology was developed to provide a high quality terminal-to-wire connection at a relatively low cost, replacing the soldering process and its associated problems. Before the crimp connector and wire are joined, the end of the connector is annealed or softened with heat so that the metal is more easily formed around the wire. The annealed end is then compressed around the conductor of the wire to produce an electrical path for the current.

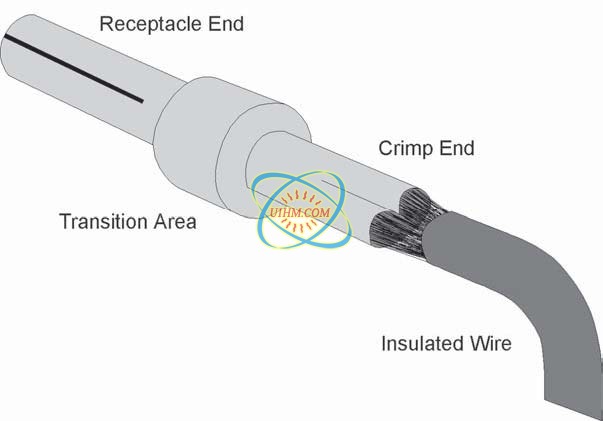

As shown in Figure 1, the other end of the connector is typically the female receptacle for a plug. This end compresses onto the pins in the plug to provide the electrical contact. Crimp-style connectors are typically made of beryllium copper. Unlike other materials, which sacrifice formability to achieve favorable spring characteristics, beryllium copper is easily stamped and formed. Once formed into the desired contact shape, the part can then be heattreated to obtain the required properties.

Figure 1: The crimp end of the copper connector is annealed with

heat so that the metal is more easily formed around the wire.

Precision Induction Heating

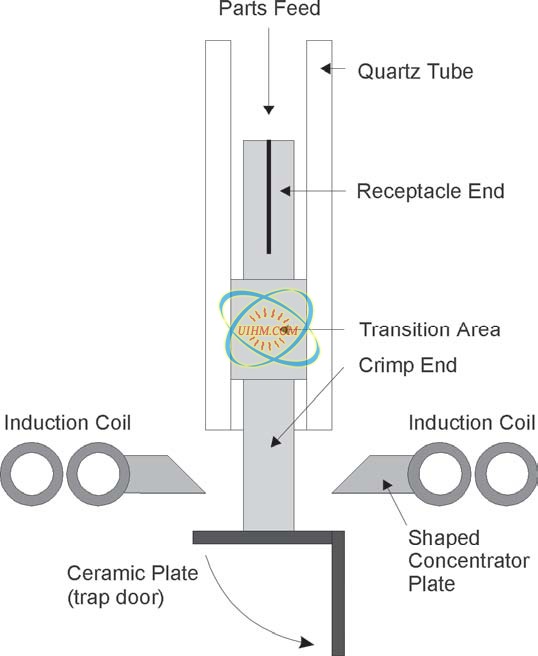

Figure 2: Note the recommended location of the coil with respect to the connector tip.

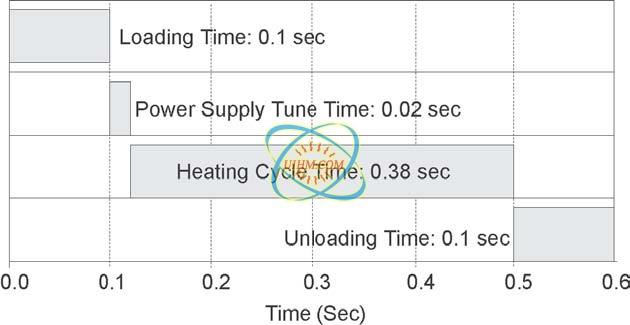

Figure 3: The satellite Star 3H was programmed for a short 0.6 second heat cycle, and required only 0.02 seconds for digital tuning. Most existing annealing systems utilize multi-turn pancake style coils and are powered by large, relatively inefficient vacuum tube power supplies. The output is often inconsistent and constant adjustments are needed to maintain product quality. The satellite Star series power supplies automatically tune their frequency of operation to the load during every cycle, providing optimized precision heat to every part. Digital frequency synthesis and microprocessor control deliver repeatable results, part after part, cycle after cycle. As a result, a 3kW satellite Star solid state power supply can often replace a much more powerful older machine, thus reducing cost.

Materials & Process To selectively anneal the crimp end of the connector without affecting the receptacle end, the satellite Star 3H power supply is used along with a specially designed, plate concentrator induction coil. The power supply delivers 3kW at the process frequency of 600kHz, providing a precise band of heat to the end of the connector. The exact process temperature will range from 900°F to 1300°F depending on the amount of annealing required. Note that the position of the connector inside the induction coil will determine the size of the annealing zone; the coil’s concentrator plate should be placed just above the tip of the crimp end of the connector as shown in Figure 2. The use of fewer turns in the coil increases the operating frequency and reduces copper loss. The higher operating frequency of the power supply and coil increases the coupling efficiency of the magnetic field to the part, and increases the efficiency of the entire process. This reduces the time required to heat to the proper annealing temperature. Since copper is a very good conductor of heat, the annealing cycle needs to be

fast. As shown in Figure 3, the satellite Star

3H power supply was programmed to

maintain a total process cycle of 0.6

seconds with an annealing temperature of

1300°F. Note that the power supply requires only .02 seconds for digital tuning and that the power supply is fully on within .12 seconds from the start of the heating cycle. To rapidly dissipate heat, the connectors should be quenched with water immediately following the heat cycle. This short heating cycle increases throughput, strictly limits the annealed area and maintains good strength associated with cold forming in the remaining section. Conclusion UIHM’s new satellite Star technology has specific advantages for this type of annealing process. The high operating frequency and rapid digital tuning of the satellite Star 3H power supply reduce both time-to-temperature and the heating cycle, thereby improving process repeatability and increasing throughput. - 4 - Precision Induction Heating

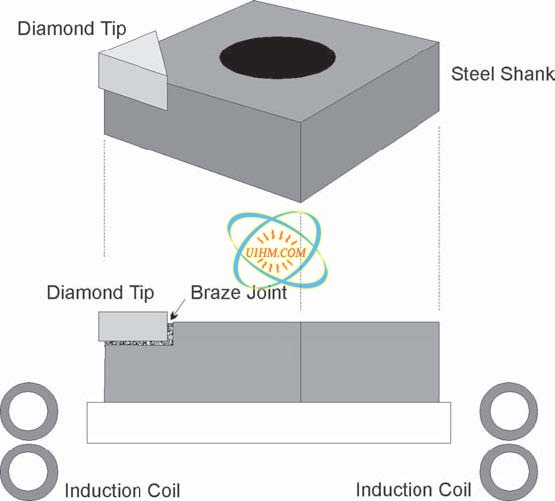

Figure 4: Diamond tips are brazed to the corners of steel shanks for high-speed machine tools. Induction Brazing Small Diamond Tips On Cutting Tools Using High Frequency Solid State Power The Problem The operating frequency range of existing induction heating power supplies is too low for effective brazing of small parts such as diamond tips for precision cutting tools. In this section, we will show how the high frequency range of UIHM’s satellite Star technology brings the advantages of induction heating to this type of process.

To manufacture polycrystalline diamond (PCD) and polycrystalline diamond boron nitrite (PCBN) cutting tips for high-speed machine tools, small (0.03” across) synthetic diamonds are brazed to the corners of carbide inserts or steel shanks as shown in Figure 4. The diamond acts as the cutting tip while the carbide insert or steel shank mounts to the fastmoving machine head. The braze joints are ductile, able to withstand considerable vibration and shock, and are easy to remove when the diamond tip breaks or wears in use. The brazing is done at relatively low temperatures to reduce the possibility of thermal damage to the PCD or PCBN section. A braze preform is used as the filler metal. Manufacturers have used flame brazing for this type of process, despite its inconsistencies and limited yield, because no induction heating power supply could operate above the critical cutting tools with precision and advanced repeatability. Digital frequency synthesis and microprocessor control deliver repeatable results, part after part, cycle after cycle. satellite Star’s continuous digital tuning provides more efficient heating,

particularly as small parts go through Curie.

Materials & Process

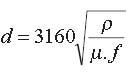

The diamonds are typically 0.03” triangleshaped

and the carbide inserts or steel

shanks vary greatly in size and shape. The shape of the coil along with the proper selection of the operating frequency delivers sufficient heat into the parts for increases. Another factor which must be considered is skin depth, which is defined as the outer layer of the material within which 80% of the induced power is dissipated. The skin depth is given by this fundamental equation: d is the skin depth in inches rho is the resistivity in ohm-inches μ is the permeability of the material and f is the operating frequency in Hz This formula dictates that for optimum heating of small parts the operating frequency of the induction equipment should be above 50kHz. However, it is important to realize that the optimum frequency for heating a part changes as the part goes through Curie. In this

application, the carbide insert or steel

shank becomes non-magnetic above

1370°F and looses the heating effect due

to hysteresis losses. Only eddy current

heating occurs above this temperature.

When taking into account the overall size

of the diamond tip and carbide insert or

steel shank, the size and design of the coil

and the resulting low coil inductance, higher operating frequencies in the 400- 700kHz are required for efficient energy transfer in this process. “Historically, the industry standard has been torch (flame) braze joints. We have used both torch and induction brazing and we are convinced that the numerous advantages offered by the UIHM satellite Star provide us with a superior braze joint.” Michael A. Yokum, Production Supervisor Cutting Tools, CITCO Operations of Landis/Gardner frequency of such a small part (critical frequency is the operating frequency above which there is no cancellation of induced magnetic field inside the part; the smaller the part, the higher the critical frequency). satellite Star technology provides high frequency coverage up to 1.2MHz to efficiently heat small parts such as diamond tips for this brazing application. The water-cooled

coil sets up a magnetic field which induces an eddy current in the part. This eddy current flows against the resistivity of the material and produces heat. With magnetic materials, the eddy current heating is complemented by heating due to magnetic hysteresis. The induced magnetic field in the part is strongest on the surface and drops off exponentially as part depth - 5 - Precision Induction Heating The satellite Star 3L was selected for this application, operating at 403kHz and programmed to produce 1400°F. The miniature diamond tips were successfully brazed to a steel shank with a ten-second heat cycle. At this rate, well over 200 parts could be brazed per hour. Conclusion The high operating frequency range of the satellite Star 3L makes it possible to use induction heating to braze very small parts such as the diamond tips required for this brazing process. Other similar manufacturing processes can also now benefit from the advantages of modern induction heating: improved repeatability, faster cycle time, pinpoint accuracy, selective heating, flexible setup and

environmental cleanliness.

RS-485 Interface

Simplifies Epoxy Curing

With Induction Heating The Problem Epoxy curing in high-volume applications poses significant problems for existing heating technology. It has been difficult to maintain precise curing temperatures for several minutes and still maintain throughput. Because of the high production volumes required, a dedicated heat source for each part is not practical. Since oven heating is also often impractical because of the inefficiencies of radiant and convective heat transfer, a better solution is required for high-volume applications. The satellite Star 3L Power Supply with its available RS-485 interface can solve this process problem. In this section we will show how to use the standard satellite Star 3L with an optical pyrometer to determine precisely how much heat is required to maintain the proper curing temperature for this process. Materials & Process

The satellite Star serial RS-485 interface

allows the power supply to be fully

controlled from a personal computer or

system controller with software packages

such as Procomm? or HyperTerminal?. Full

operational control is available, with

commands to set the voltage, control the

heat, start and stop the heat cycle, and set

the heat cycle timer. Full status readout is

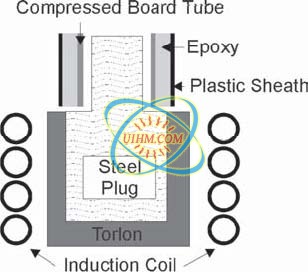

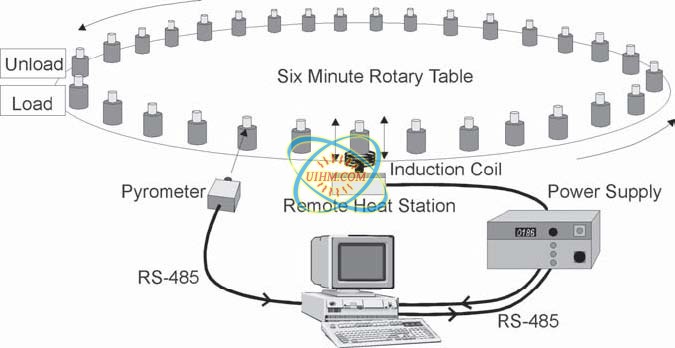

also available by using the “READ” command. The satellite Star 3 responds with a data stream consisting of DC voltage, DC current, DC power, operating frequency, heat-on time, power supply status, and internal fault diagnostics. Since the data request, gathering and transmission take approximately 100ms, the full heat cycle characterization is achievable. This application involves heating a small steel plug, which in turn provides the thermal energy for curing the epoxy on the part. As shown in Figure 5, the plug is 1.125” in diameter and rests in a Torlon plastic mold. For a complete cure, the temperature at the epoxy surface must be maintained at 400°F for six minutes. Figure 6 illustrates the tooling at the production site: a rotary table with space for 30

steel plugs placed equidistant along the circumference. The process allows for 4 seconds of heating time per 6-minute cure cycle. The parts are loaded on the steel plugs at one station and heated to a surface temperature of 450°F in 4 seconds. The satellite Star 3L delivers 3kW of power at 186kHz for this application. As the table rotates each plug away from the induction coil, they gradually transfer their heat to the epoxy assemblies and torlon plastic. At the end of the cycle, the parts are unloaded off of the steel plugs, and then a new heat cycle begins with fresh parts. Each steel plug retains some of its heat from one heat cycle to the next. An optical pyrometer measures the temperature of each plug just before it enters the induction heating coil. Using the RS-485 interface, a determination is made as to how much energy needs to be delivered to the plug to bring its temperature back to 450°F. The satellite Star 3L is instructed through the RS- 485 interface to deliver the right amount of heat for the predetermined time to each steel plug. Conclusion The satellite Star 3L’s RS-485 interface

connection, together with the optical

pyrometer’s heat measurement, enabled

induction heating to be used successfully

for this application. With the necessary

temperature data and communications link, the power supply can precisely maintain the temperature of the steel plugs for correct curing of the epoxy.

Figure 5: The steel plug transfers its heat to the epoxy for curing.

Figure 6: The computer instructs the power supply to deliver the required energy to heat

the steel plug to 450° F.

- 6 -

Precision Induction Heating Figure 7: The solder preform on the connector end cap must be activated without heating the rest of the connector.

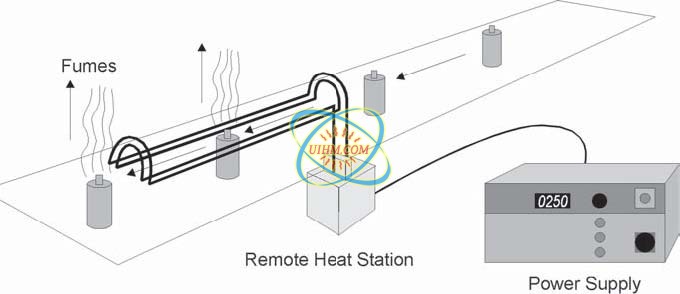

Figure 8: Both the low-voltage power supply and remote heat station can be located out of the path of the corrosive flux fumes produced by this soldering application. Small Remote Heat Station

Solves RF Connector Soldering Issues On Conveyor Line The Problem Assembly line production of RF connectors is difficult to handle with existing induction heating systems. The flux fumes produced by the process are highly corrosive and damaging to both the power supply and its attached induction coil. Also, the high voltage requirements of most existing power supplies produce excessive arcing. In this section, we will show how a low voltage, compact remote heat station available for satellite Star power supplies can make the crucial difference for this induction heating process. Materials & Process The RF connectors produced during this process are steel cups about 1.0" in diameter and 3” long, travelling at a rate of 1800 pieces per hour on a conveyor system. As shown in Figure 7, the end cap needs to be soldered onto the can to form a hermetically-sealed connector. A solder preform is placed on the joint area before it

reaches the induction heating coil. The

end of the connector is placed flush with

the coil turns to ensure proper heating

of the two pieces.

A good solder joint is achieved only if both pieces simultaneously reach the soldering temperature of 600°F. The solder is flux core type tin-lead wire; the flux outgasses during the heating cycle. Selective heating is required to melt the solder onto the end cap of these connectors. Oven heating is not practical because it heats the entire connector and destroys the electronic components inside. Flame heating will not produce repeatable results. Induction heating is therefore a good heating solution for this process, but the corrosive effects of the flux and arcing tendencies of existing induction power supplies must be overcome. To minimize arcing tendencies, UIHM’s new satellite Star power supplies operate at lower, safer voltages than most older equipment. To remove the power supply from the conveyor line area and the corrosive effect of the solder flux, a variety of compact remote heat stations are available. The power supply can

actually be located up to 200 feet away

from the induction coil, depending on the

application.

For this soldering application, a satellite

Star 3L power supply produced 3kW at

250kHz. A small remote heat station and a

channel-type induction coil were used to

heat the top end of the RF connector and

the end cap. As shown in Figure 8, corrosive flux flumes evaporate off the part and will tend to condense on any cool metal surface in the vicinity. The heat station can be located underneath the conveyor line, outside of the natural path of the flux fumes, and connected to the power supply with a flexible, low-voltage cable. A fume hog is recommended on top of the induction coil to vent the flux fumes coming off the joint area. To provide additional protection against arcing, a nonconductive sleeve is slipped over the copper coil turns. Conclusion satellite Star technology eliminates the RF connector soldering issues associated with this process. By reducing the power supply’s voltage requirements and removing both the power supply and heat station from the path of the solder flux

fumes, the RF connectors can be produced with high throughput and improved yield without damage to the heating components. - 7 - Precision Induction Heating

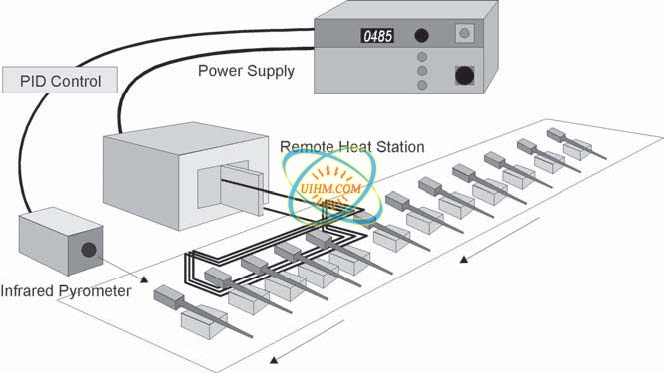

Figure 9: The satellite Star power supply’s output is controlled by the infrared pyrometer’s signal, forming a closed loop control system.

Figure 10: The peak picker mode of the infrared pyrometer picks the “peak” temperature of each part and controls the power supply to maintain the part temperature at 900° ± 10°F.

Closed Loop Temperature Control Improves Tempering Process For Steel Punches Introduction Manufacturers of steel punches have problems processing the head of the punch to the proper hardness. If the steel is left too hard, it will crack on impact; if too soft, it mushrooms over. The ends are therefore tempered after hardening to achieve the optimum hardness and toughness. There are manufacturing problems with achieving a consistent

hardness from punch to punch because

the power output from most older

induction systems tends to drift over time.

In this section we will show how

UIHM’s satellite Star power supplies

accept control signals from an infrared

pyrometer, forming a closed loop

temperature control system to solve this

application’s repeatability problem.

Materials & Process

The steel punch has a 0.25” square head

and a tapered steel end. After the punches

are manufactured from raw steel, they

undergo an intensive heat treating cycle.

Both ends are selectively hardened to 60+

on the Rockwell scale. The head of the

punch is then tempered to a lower

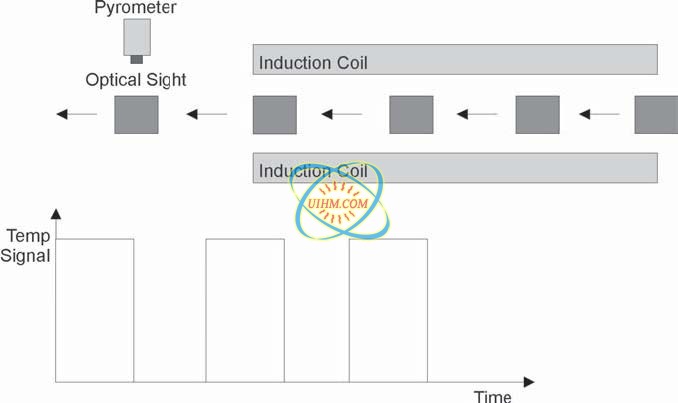

hardness by heating it to 900° ± 10°F. The parts are then air-cooled to obtain the desired hardness. As shown in Figure 9, the punches are indexed through the channel-shaped induction coil. Each part is in the coil for four seconds; the coil accommodates four parts at a time. The index length is 1.5 inches with a 1-second dwell at each location. The parts are loaded and unloaded during the dwell time. An infrared pyrometer measures the

temperature of the punches. The pyrometer is set on peak picker mode so that it can correctly read temperature even if the work piece is moving and is only in the field of view for a short time. It is also capable of viewing parts with variable spacing , which occurs if there is an empty location due to a misfeed. The UIHM satellite Star 3L solid state induction heating power supply accepts multiple control signals from an infrared pyrometer and other external sources with 0-20mA, 4-20mA, 0-10V or 0- 5V input control signals with excellent resolution. This results in a closed loop temperature control system which transfers power with accuracy and precision to the punches passing through the coil. Figure 10 shows how the pyrometer works in peak picker mode. The pyrometer’s circuitry responds to the highest instantaneous value of the temperature and holds this value even if the temperature source is interrupted by one of the conditions listed above. The indicated temperature can be set not to decay during the index cycle of the punches (when there is no temperature

readout) by adjusting the peak picker

decay rate control. The pyrometer sends a

control signal to the power supply which

regulates the power output. The pyrometer

also compensates for process temperature fluctuations such as those due to varying amounts of quench left over on some parts from the preceding hardening cycle. Conclusion The satellite Star 3L power supply accepts the pyrometer’s control signal to form a tight closed loop temperature control system. The system consistently regulates the temperature of the steel punches so that the tempering process is successful and throughput can be maintained with excellent repeatability.

Newest Comment

Post Comment