Video of UM-CNC auto saw tooth induction welding machine

Technical Features:

1, Automatic choose gear, feeding, wire feed welding process

2, Accurate, welding firm, stable quality

3, New gear selection system

4, Temperature control the welding process can be fine-turning and auto-tempering function, to adapt to a variety of special welding requirements.

5, The whole process of computer control, with memory and query functions

6, CNC control, safe and reliable

7, Advanced UHF heating controller, small size, low power consumption and high efficiency

8, Graphical user interface, clear concise, easy to grasp the operation of the program

9, Can be designed according to customers' special requirements

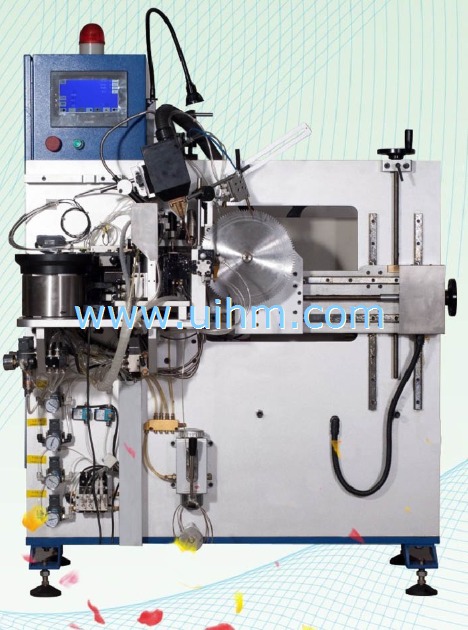

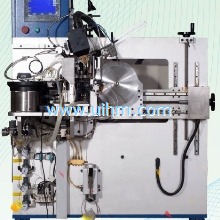

UM-CNC auto saw tooth induction welding machine

| Saw Blade OD | 80~500mm | Working Power | 6KW |

| Tooth Face Angle | -5º~+25º | Total Power | 6.5KW |

| Tooth Length | 3.5~14mm | Working Pressure |

6kg/cm |

| Tooth Width | 1.5~6.5mm | Ventilated Ability |

>=5m |

| Tooth Thickness | 1.5~3.0mm | Cooling System Power | 1.5KW |

| Welding Ability | 18t/Min | Cooling Water Flow Rate | 22L/Min |

| Welding Accurate | <=0.05mm | Size | 1200x960x1520mm |

| Power Supply | 220V/50Hz | Net Weight | 323kg |

UM-CNC auto saw tooth induction welding machine

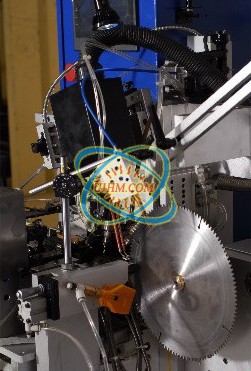

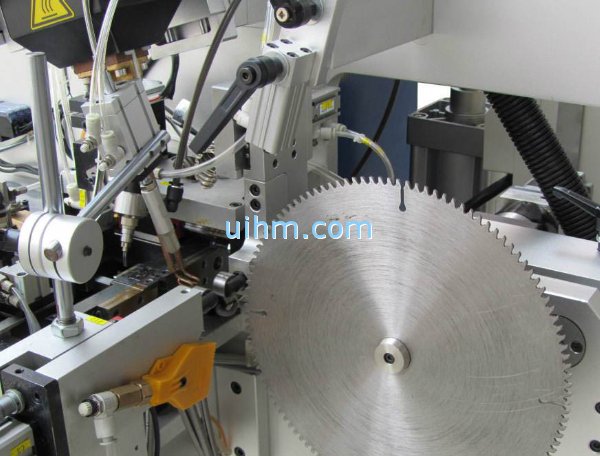

UM-CNC saw teeth auto brazing machine (7)

UM-CNC saw teeth auto brazing machine (8)

UM-CNC saw teeth auto brazing machine (9)

UM-CNC saw teeth auto brazing machine (10)

UM-CNC saw teeth auto brazing machine (11)

UM-CNC saw teeth auto brazing machine (12)

UM-CNC saw teeth auto brazing machine (13)

UM-CNC saw teeth auto brazing machine (14)

UM-CNC saw teeth auto brazing machine (15)

UM-CNC auto saw tooth induction welding machine

Machine: UM-05AB-UHF, UM-06AB-UHF, UM-05A-UHF, UM-06A-UHF

Alloy Serrated Automatic Welding Machine

CNC automatic UHF induction brazing saw teeth

IGBT MF, RF, HF and UHF induction heating equipment is widely used in the following industries:

(A) heat treatment industry (hardening, annealing, tempering and stress relieving):1. Hardware tools high-frequency hardening heat treatment, such as; vise, hammer, locking pliers, wrenches, screwdrivers

2. Variety of steam, motorcycle parts high-frequency hardening heat treatment, such as: crankshaft, connecting rod, piston pin, camshaft, valves, various gears within the gearbox, a variety of fork, all kinds of spline shaft, drive axle, each high-frequency hardening heat treatment of the kinds of small shafts, crank pin, rocker arm, rocker shaft

3. Hydraulic components, such as: a rotor of the plunger piston pump, rotor pump, various valves on the other to the heat treatment of high-frequency hardening of the shaft, the gear pump gears, etc.

4. Automotive, machinery and equipment, electric tools, gear, bearing high-frequency hardening heat treatment

5. Variety of woodworking tools, such as: ax, planer quenching

Wheels of a variety of automotive, motorcycle, marine and engineering equipment, machine axis IF quenching, large parts of the annealing, tempering and stress relieving.

(B) the welding industry (brazing)

1. Welding of various turning tools, planer, milling machining and cutting tools

2. Welding of various diamond tools, such as: welding diamond saw blades, diamond drill

3. Various shaped drill head column Button Bits, drill Yan briquette, riveting rod drill carbide brazed

4. Various shearer teeth welding, various digging machine cutter welding

5. Various mechanical welding tool

Air conditioners, refrigerators, refrigeration system brass brazing, pipe brazing, as well as brass and aluminum tubes brazed

(C) forging industry

1. Heat pier variety of standard parts, non-standard parts, pieces of copper, steel and aluminum parts casting and forging

2. Hardware tools such as pliers, wrenches before forging heating

3. Solder with solder tail caudal peduncle cone drill head forging

4. A extrusion molding on the stainless steel container.

(D) the precious metal smelting industry

The sample melting of steel, iron, copper, aluminum and other tests, as well as gold, silver and other precious metals smelting

UM Series press feed screw barrel induction heating equipment, the main application industries:

1, the plastics and rubber industry, such as: plastic film blowing machine, drawing machine, injection molding machines, blow molding machines, blow molding machines, plastic machines, molding machines, bag making machine, pipe production line, plate production line, granulating machine, plastic pressure machine, foaming machine rubber extruder, vulcanizing machine, cable extrusion machine, etc.2, the pharmaceutical and chemical industry, such as: medicine dedicated infusion bag, plastic equipment production lines, chemical industry liquid heating duct

3, the energy, the food industry, such as: crude oil pipeline heating, food machinery, such as Roasting Machine need for electric heating equipment

4, the building materials industry, such as: gas pipeline production line, plastic pipe production line, PE plastic rigid flat net, geotextile mesh unit, automatic hollow molding machine, PE honeycomb board production line, single-double wall corrugated pipe extrusion production line, composite cushion film crew rigid PVC pipe, foam core pipe production line, PP extrusion transparent sheet production line, extruded polystyrene foam pipe, PE stretch film plant

5, printing equipment, dry heat

6, other similar industry heating

UM pipeline heating, preheat and post-weld treatment induction heating equipment applications and applicable industry:

1, heated crude oil pipeline (crude oil pipeline installation, delivery of crude oil extraction, petrochemical, pipeline transportation of natural gas)2, sheet metal, pressure vessels, generating sets and other large, shaped workpieces before welding preheat and post-weld heat treatment, stress relief, etc., applicable machining industry, petrochemical, aerospace, boiler, shipbuilding, metallurgy, iron and steel, construction of railway bridges, gas cylinders and pressure vessel manufacturing, vehicle manufacturing, the construction of the nuclear power unit

Newest Comment

1) joining ball of diameter 2-5 mm at the tip of shaft of diameter 2.4 mm

and

2) joining pipe of 1 mm diameter to the shaft of diameter 2.4mm in "T" shape

Material is Stainless steel of AISI 300 Series

Please send me the equipment specifications and quotations. Is it possible to braze more than one items ,if yes, then which equipment will be recommended.[please find detaild info of my Email]

Post Comment