Clean and fast heat being supplied to the heated workpiece meets the considerably increased requirements with regard to environmental protection. The surroundings is not exposed

to any thermal and atmospheric pollution. The particular advantage of this process is to produce the heat inside the workpiece without the need for any external heat source.

According to the physical law of induction an alternating magnetic field is generated around each electrical conductor through which an alternating current is flowing. By considerably

increasing these magnetic fields, metals brought into close proximity will be heated by eddy currents produced within the metal. Heating by induction makes use of the capability

of the magnetic field to transmit energy without direct contact. This means heating is not done by contact transmission

such as known in resistance heating in light bulbs, heating plates or electrical furnaces where the direct current flow causes resistance wires to glow.

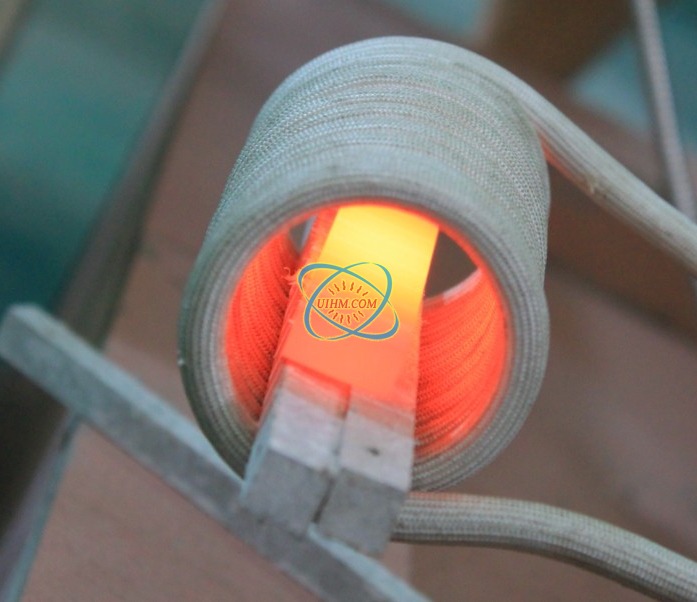

A basic problem of induction heating is to create a sufficiently

intense electro-magnetic field and to position the component to be heated within the center of the field in such a way as to obtain optimum transmission of energy from the electrical conductor to the workpiece. Normally this is achieved by forming the electrical conductor also referred to as inductor or coil with one or more turns. The workpiece is positioned in the centre of the coil, thus concentrating the magnetic field onto the component. The field will then force the electrical current to flow within the workpiece. According to the law of transformation, the strength of the current flow in the component is equal to that in the coil. To create a sufficiently

strong magnetic field, th current flow in the coil must be very high (1000 – 10.000 A), normally a current of this intensity would cause the coil to melt; by comparison, 10 A is the current flow within a 2000 W heating furnace. In order to avoid this problem, the coils are made of water cooled copper tubing. Another method of creating a strong alternating

magnetic field is to increase the frequency of the current. Normally the electrical mains supply to both household and industry operates at a frequency of 50 Hz, i.e. the current will change direction 50 times per second. Depending upon the application, an induction heating equipment will operate at a frequency of between 50 and 1 million Hz.