induction hardening

Principal methods

Single shot hardening

In single shot systems the component is held statically or rotated in the coil and the whole area to be treated is heated simultaneously for a pre-set time followed by either a flood quench or a drop quench system. Single shot is often used in cases where no other method will achieve the desired result for example for flat face hardening of hammers, edge hardening complex shaped tools or the production of small gears.

In the case of shaft hardening a further advantage of the single shot methodology is the production time compared with progressive traverse hardening methods. In addition the ability to use coils which can create longitudinal current flow in the component rather than diametric flow can be an advantage with certain complex geometry.

There are disadvantages with the single shot approach. The coil design can be an extremely complex and involved process. Often the use of ferrite or laminated loading materials is required to influence the magnetic field concentrations in given areas thereby to refine the heat pattern produced. Another drawback is that much more power is required due to the increased surface area being heated compared with a traverse approach.

Traverse hardening

In traverse hardening systems the work piece is passed through the induction coil progressively and a following quench spray or ring is utilised. Traverse hardening is used extensively in the production of shaft type components such as axle shafts, excavator bucket pins, steering components, power tool shafts and drive shafts. The component is fed through a ring type inductor which normally features a single turn. The width of the turn is dictated by the traverse speed, the available power and frequency of the generator. This creates a moving band of heat which when quenched creates the hardened surface layer. The quench ring can be either integral a following arrangement or a combination of both subject to the requirements of the application. By varying speed and power it is possible to create a shaft which is hardened along its whole length or just in specific areas and also to harden shafts with steps in diameter or splines. It is normal when hardening round shafts to rotate the part during the process to ensure any variations due to concentricity of the coil and the component are removed.

Traverse methods also feature in the production of edge components, such as paper knives, leather knives, lawnmower bottom blades, and hacksaw blades. These types of application normally utilise a hairpin coil or a transverse flux coil which sits over the edge of the component. The component is progressed through the coil and a following spray quench consisting of nozzles or drilled blocks.

Many methods are used to provide the progressive movement through the coil and both vertical and horizontal systems are used. These normally employ a digital encoder and programmable logic controller for the positional control, switching, monitoring, and setting. In all cases the speed of traverse needs to be closely controlled and consistent as variation in speed will have an effect on the depth of hardness and the hardness value achieved.

Equipment

Power required

Power supplies for induction hardening vary in power from a few kilowatts to hundreds of kilowatts dependent of the size of the component to be heated and the production method employed i.e. single shot hardening, traverse hardening or submerged hardening.

In order to select the correct power supply it is first necessary to calculate the surface area of the component to be heated. Once this has been established then a variety of methods can be used to calculate the power density required, heat time and generator operating frequency. Traditionally this was done using a series of graphs, complex empirical calculations and experience. Modern techniques typically utilise finite element analysis and Computer-aided manufacturing techniques, however as with all such methods a thorough working knowledge of the induction heating process is still required.

For single shot applications the total area to be heated needs to be calculated. In the case of traverse hardening the circumference of the component is multiplied by the face width of the coil. Care must be exercised when selecting a coil face width that it is practical to construct the coil of the chosen width and that it will live at the power required for the application.

Frequency

Induction heating systems for hardening are available in a variety of different operating frequencies typically from 1 kHz to 800 kHz. Higher and lower frequencies are available but typically these will be used for specialist applications. The relationship between operating frequency and current penetration depth and therefore hardness depth is inversely proportional. i.e. the lower the frequency the deeper the case.

Examples of frequencies for various case depths and material diameters

| Case depth [mm] | Bar diameter [mm] | Frequency [kHz] |

|---|---|---|

| 0.8 to 1.5 | 5 to 25 | 200 to 400 |

| 1.5 to 3.0 | 10 to 50 | 10 to 100 |

| >50 | 3 to 10 | |

| 3.0 to 10.0 | 20 to 50 | 3 to 10 |

| 50 to 100 | 1 to 3 | |

| >100 | 1 |

It can be seen from the above table that the selection of the correct equipment for any application can be extremely complex as more than one combination of power, frequency and speed can be used for a given result. However in practice many selections are immediately obvious based on previous experience and practicality.

The main benefit of induction heating for hardening is that it takes just a few seconds. In a furnace, the same process can take hours or even days. Why is that possible?

The answer is that induction is phenomenal at generating heat fast. This, in turn, means you can integrate hardening in the production process. Hardening in a furnace, on the other hand, is more time-consuming (greater heat loss) and requires moving the components either to your own furnace or to that of a sub-contractor.

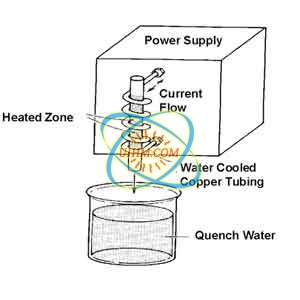

Induction hardening is the process of hardening steel by heating it. It is done by an alternating magnetic field to a temperature above or within a specific transformation range. It is straight away followed by quenching. This procedure of hardening can be specifically applied to both full as well as surface hardening methods. This is the kind of heat treatment process in which the metal part is heated and later it is quenched. The metal which is quenched further undergoes a martensitic transformation in order to enhance the hardness and brittleness of the specific part. Principal Techniques:This hardening process can be performed mainly by two procedures:Traverse HardeningSingle-shot HardeningIn the traverse hardening systems, the work piece to be worked on is repeatedly passed through the induction coil and a quenching spray is being used. It is majorly used in the production of some shaft type components including steering components, drive shafts and power tool shafts etc. The quench ring that is being used can also be an integral component. This method is also applicable in the production of edge components such as: hacksaw blades, leather knives, paper knives and lawnmower bottom blades.In the single-shot hardening method the component which is to be treated is held statically or is rotated inside the coil in which the complete area is being heated for a particular time which is pre-set. This method is generally used for edge hardening of complex shaped tools, flat face hardening of hammers and for the production of small gears. Requirements for Induction Hardening:As far as this heating procedure is concerned, three things which are majorly required for this process to occur are as follows:1.A high frequency electrical power source2.A work coil to generate the alternating magnetic field3.An electrically conductive work piece which is to be heatedBefore this heat treatment process is performed, it is necessary to make a note of the chemistry of the metal, the adjustment of the temperature of the metal and last but not the least the characteristics of the metal. Tips for Successful Induction Hardening of Steels:The selection of steel plays a vital role in this heat treatment process. Steel parts are mainly hardened to get hold of some specific properties such as wear resistance, tensile and fatigue strength. Moreover, it can either be done on a specific part of the work piece or throughout the entire part. The procedure involves heating the work piece to a temperature which is higher than the austenitizing temperature and then the steel is allowed to cool at a rate which is fast enough to transform it to fully martensitic structure. These hardening service providers must have a license which states that these are authorized to perform the different types of heating treatments and the company or the service provider must use the right equipments and procedures for hardening.

We are blessed with a number of improved and useful devices and systems that have changed our life. From health, education, communication to entertainment, science and technology has touched every area. Health industry is witnessing a lot of improvements as a result of the introduction of scientific interference. Now, it has become easy to treat some of the problems that doctors could not handle in the past. The process of induction hardening is almost similar to any other heat treating operations. It is mainly performed to harden parts. The procedure is dependent on various factors to be successful, adjusting the temperature of the material, the general ability and chemistry of the material to harden, proper cooling of the material so that the transformation of the martensite can occur. When one or more than one of these critical characteristics are not present, the material may remain soft entirely or it may end with soft spots. So, it is very essential to check whether all these factors are present or not. Most of these factors help in quenching and heating of the parts. There are different types of heat treatment processes, including Annealing, Ageing, Hardening, Induction Annealing, Carbonitriding, Case Hardening, Carburising, Induction Hardening, Stress Relieving, Shot Blasting, Shot Blasting, Normalising and Tempering to materials like Cast Irons, Alloy Steels, Stainless Steels, Die Steels, Tool Steels, Carbon steels etc. Ageing is the process that causes structural change. It may occur in certain alloys and certain metals at atmospheric temperature or at higher temperatures (also called as artificial ageing). As a result of ageing, the hardness value and maximum stress are increased. You should make it sure that there is some reduction in ductility. Artificial ageing is a process in which the ageing is created by heating at high temperature. It results in precipitation hardening. It is one of the best heat treatment processes. It is quite essential to adjust the temperature of the material so that the austenitic phase can occur. In certain cases, based on the material, it may be essential to hold the temperature for a certain amount of time. It is done to allow the material to avoid undesirable by-products and also allow to fully transforming. There are many other types of heat treating operations that are used. Annealing, Carbonitriding are two of the popular heat treating processes. Annealing is a process in which steel is heated and then the temperature is adjusted properly. Then the cooling is done at a suitable rate, with machinability, with the object of improving softness, of obtaining a desired structure and of removing stresses and cold working properties. Generally the steel is heated to a certain temperature at which carbide is partly or fully taken into solution.

Induction hardening is a very widely used industrial process for the surface hardening of steel. The steel components to be hardened are heated by means of an alternating magnetic field to a temperature within or above their transformation range. This heating process is then reversed by immediate quenching or rapidly cooling down the metal components to room temperature. Just as with case hardening or face hardening the core of the metal, the component remains unaffected by the treatment and its physical properties and advantages are unaffected too. But it is now sheathed in a much harder alloy that has a higher carbon content.The process requires a source of high frequency electricity that is used to drive a large alternating current through a coil. The passage of current through this coil generates a very intense magnetic field that is rapidly changing in its polarity in the space within the coil. The metal component that is to be hardened is inserted into this rapidly alternating magnetic field and the current generated within the object itself rapidly heats it up. This hardening results in a layer of a highly wear resistant alloy around the component. This makes these sort of metal pieces used widely in automotive and industrial applications where long life and wear resistance are required.There are two primary types of hardening. Single shot or static hardening is the process where the component is contained within the coil in its entirety and either held static or rotated. The hardening effect is achieved all over the surface of the object simultaneously. The advantage is a quicker process due to the fact that the entire component is being treated in one go itself. The quenching process or the cooling down is also done at one go for the entire component. The drawback is the higher power requirement of the induction coil required for the hardening process. Traverse hardening is the other type of induction hardening process widely used for long components like axle shafts and steering columns for automotive applications. The induction is actually done by a ring type inductor that creates a band of heat that needs to be moved along the length of the component. The quenching process is also done in a similar manner. The advantage is that less power is required and by varying the speed of the ring variable hardening is achievable. The drawback is the additional time taken per component.

With the development of science and technology, a number of innovative and improved devices and systems have been introduced. From entertainment, health, communication to travel, each and every arena has undergone a change. This rapid growth has also lead to the introduction of induction hardening, an effective and useful heating method. Induction hardening is generally performed to harden metal parts. However, there are certain factors, which play a great role to make this heating process a successful one. Its essential to take note of the metal’s chemistry, the adjustment of the temperature of the metal so that austenitic stage can occur, the characteristics of the metal as well as its capacity to cool down very fast. Each of the above mentioned factors are essential for this hardening process. If any of these factors is absent, the metal might not harden or soft spots might occur on the metal. These important features or factors have great control over the heating or quenching of the metal. However, its not only induction hardening procedure that helps in the heating treatment of metals. There are also other kinds of heating methods like annealing, hardening, tempering, carbonitriding, inducting annealing, tempering, homogenizing, case hardening, shot blasting, normalizing, stress relieving etc to materials like cast irons, carbon steels, die steels, alloy steels, tool steels and stainless steels. Quenching is a very important part in order to get the desired hardness of a metal. Improper quenching may lead to a variety of problems. Usage of a wrong quenchant for a specific metal may cause the process of quenching to become slow. So, it’s important to check out whether right and ample amount of quenchant is used for removing the heat or not. Polymer is mostly used by the water-based quenchants. The use of it basically slows down the cooling process and prevents the occurrence of cracks. However, including too much of polymer isn’t a wise idea. This chemical compound may reduce the heat removing ability and cause the metal to remain soft. Also check out whether the item is properly cooled or not or else the residual heat will tamper the metal. Induction hardening process is used mainly for the steel alloys. This heating treatment mainly aims to improve the wearing behavior, durability and fatigue life of metals and alloys, which are usually used to make springs, gears and shafts. It’s only the professional heat treatment organizations that has the perfect set up and right knowledge to offer. Here are some tips that will help you to find out an expert in heat treatment service. The hardening service provider must be licensed and authorized to perform the different types of heating treatments. The company you opt must provide quality services. Thus, it’s important to learn about the past records of the company in relation to the heating treatment. Find out whether the company uses the right equipments for hardening. Also, take into consideration the UIHM Induction Heating company’s experience in offering efficient and safe metal hardening services. However, always compare the prices of the different service providers in this industry while finding out the best deal online.

Camshaft induction hardening 2

Camshaft induction hardening

Chain heat treatment

Crankshaft induction hardening

Customized coil for camshaft induction hardening 2

Customized coil for camshaft induction hardening

induction hardening 2

induction Hardening large rings and gears

Raceway and balltrack induction hardening

twin tailstocks induction quenching

vertical Induction hardening machine

Newest Comment

No Comment

Post Comment