- HF Induction Brazing

- ┣━━ HF Induction Brass Solder

- MF Induction Forging

- Induction Hardening

- HF Induction Quenching

- HF Induction Annealing

- Induction Tempering or Preheating

- Induction Melting

- ┣━━ Rare Metals Melting

- ┣━━ High Capacity Melting

- Induction Shrink Fitting

- Induction Thermal Treatment

- Induction Heating for Aerospace

- Induction Bonding

- Induction Soldering

- Induction Welding

- Induction Jointing

- Other Induction Applications

-

induction annealing treatment

Annealing is a heat treatment in which material is exposed to an elevated temperature and slowly cooled. Annealing of the material changes physical properties of the material such as strength and hardness.UIHM induction annealing machines are designe

2009/10/02

-

induction heating saw teeth

induction heating saw teeth

2009/10/02

-

RF induction evaporation

induction evaporation

2009/10/02

-

auto induction hardening

auto induction hardening

2009/10/02

-

Induction bending for big pipes

Induction bending

2009/10/02

-

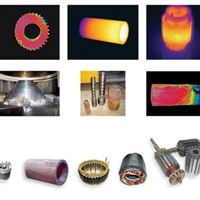

Induction Heating Applications Show 3

induction Heating is very popular for various of applications such as Annealing Bonding, Rubber/Metal Brazing , Cap Sealing ,Carbide Tipping, Catheter Tipping ,Crystal Pulling , Curing , Forging ,Getter Firing , Hardening , Heat Treating , Hot Forming ,L

2009/10/01

-

Induction Heating Applications Show 2

induction Heating is very popular for various of applications such as Annealing Bonding, Rubber/Metal Brazing , Cap Sealing ,Carbide Tipping, Catheter Tipping ,Crystal Pulling , Curing , Forging ,Getter Firing , Hardening , Heat Treating , Hot Forming ,L

2009/10/01

-

Induction Heating Applications Show 1

induction Heating is very popular for various of applications such as Annealing Bonding, Rubber/Metal Brazing , Cap Sealing ,Carbide Tipping, Catheter Tipping ,Crystal Pulling , Curing , Forging ,Getter Firing , Hardening , Heat Treating , Hot Forming ,L

2009/10/01

-

Induction Heating six wire bundles

Heating six wire bundles Objective Heating the ends of six wires on a starter motor to remove the electrical varnishesMaterial Starter motor with six wire bundles, each wire consists of 3wires 0.04” (1.0mm) diameter eachTemperature 1202 F (650 C)Freq…

2008/08/03

-

Induction Heating Nitinol spring

Heating Nitinol spring Objective To heat a nitinol spring assembly to 800F (426.6C) for shape setting applicationMaterial 0.018” (.457mm) Nitinol wire wrapped around a 0.08” (2.03mm) Nitinol mandrel 15” (381mm) longTemperature 800F (426.6C)Frequenc…

2008/08/03

© Copyright 2025. uihm.com All Rights Reserved.