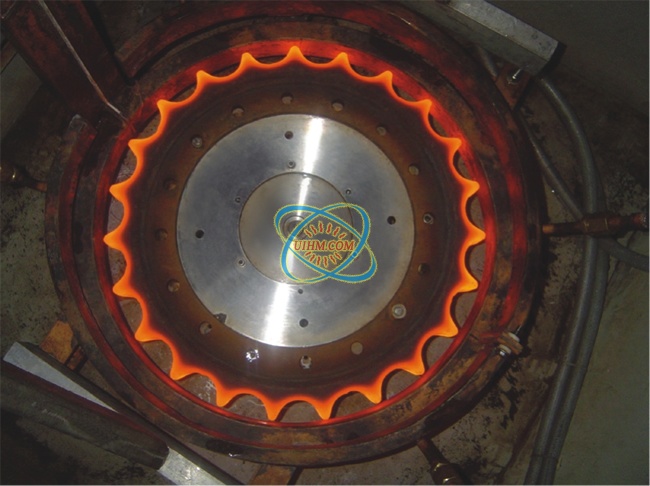

UIHM induction surface hardening applications one application: under torsion and bending load of the alternating workpieces requiring surface layer under the Ministry of higher stress than the heart or abrasion on the surface to be made to strengthen the demand for carbon the amount of We = 0.40 ~ 0.50% steel. Second, the process method of rapid heating and immediate quenching combination. To be processed by rapid heating to quenching temperature of steel surface, ranging from the rapid cooling that the heat reached the center, only to surface hardened to martensite, the center is still not the original plastic hardening, annealing toughness (or are fire and quenched) organization. Three main methods:Induction heating equipment surface hardening (high frequency, intermediate frequency, frequency), the flame surface hardening heat, electrical contact heating surface hardening, surface hardening electrolyte heating, laser heating surface hardening, electron beam heating surface hardening. Fourth, the Billet heating machine surface hardening (a) basic principles: the hollow copper tube placed around the workpiece into the sensor, the access frequency or high frequency alternating current, the surface of the workpiece with the frequency of the induced current, the part surface rapid heating (a few seconds to heat up 800 to 1000 degrees, the center remains close to room temperature) immediately after the cooling water (or immersion oil quench), the surface layer hardened. (As shown in the animation below) (b) the frequency of use at room temperature when the heating current flowing into the workpiece surface induction depth δ (mm) and the current frequency f (HZ) is the relationship between the frequency increases, current penetration depth of the lower layer hardenability reduced. The current frequency used are: 1, high-frequency heating: 100 ~ 500KHZ, used 200 ~ 300KHZ, high-frequency heating for the tube, hardened layer depth of 0.5 ~ 2.5mm, suitable for small and medium sized parts. 2, medium frequency heating: current frequency of 500 ~ 10000HZ, used 2500 ~ 8000HZ, power supply equipment for the mechanical frequency heating device or SCR frequency generator. Hardened layer depth of ~ 10 mm. Suitable for large diameter shaft, the gear and so on. 3, frequency heating: current frequency is 50HZ. The use of mechanical power-frequency heating equipment, hardened layer depth of up to 10 ~ 20mm, suitable for large diameter of the workpiece surface hardening. (C), inductive heating surface hardening applications: a comparison with ordinary Hardening: 1, fast heating, the body can expand the A transition temperature range, shorten turnaround time. 2, obtained after quenching the workpiece surface the hidden fine martensite, the hardness slightly higher (2 ~ 3HRC). Lower brittleness and higher fatigue strength. 3, after the process is not easy to deal with oxidation and decarbonization of the workpiece, the workpiece can be treated and even some direct assembly to use. 4, hardened layer depth, easy-to-control operation, easy to mechanization and automation. Fifth, the flame surface heating for hardening steel 35,45 in carbon steel and alloy steel 40Cr and 65Mn, gray iron, alloy cast iron flame surface hardening. With acetylene – oxygen or gas – oxygen mixture rapidly heated jet flame burning the workpiece. Quenching temperature to reach the surface immediately after water cooling. Hardened layer depth of 2 ~ 6mm, otherwise it will cause serious overheating and deformation of surface cracking.

Newest Comment

Regards

Adnan Turhar ([email protected])

Global Trade & Marking S.A.

Post Comment