Medium frequency vacuum induction melting furnace

Feature and application:

Whole Stainless steel design

Horizontal furnace and side opening structure to load samples conveniently

Compact furnace structure, save space

IGBT module power supply

Widely applied in the university and institute labs to melt metals(such as stainless steel, Ni base alloy, copper, alloy steel, Nickel-Cobalt alloy, rare earth, Nd-iron-boron etc) in vacuum or protecting gas atmosphere.

Also proceed vacuum refining processing and precision casting for the alloy steel.

Specification

item: induction vacuum melting furnace

Cold state final vacuum degree: 5×10-3Pa

Rating temperature: 1700℃

Rating power: 20KW

Crucible capacity: 1000g(liquid)

Pressure rising ratio: ≤2Pa/H

Max Frequency: 20KHz

Max melting weight: 5kg/melting cycle

Structure introduction:

It consists of furnace lid, furnace body, swinging gear, teeming device, vacuum system and medium frequency induction power supply control system, etc.

The furnace body is made of stainless steel.

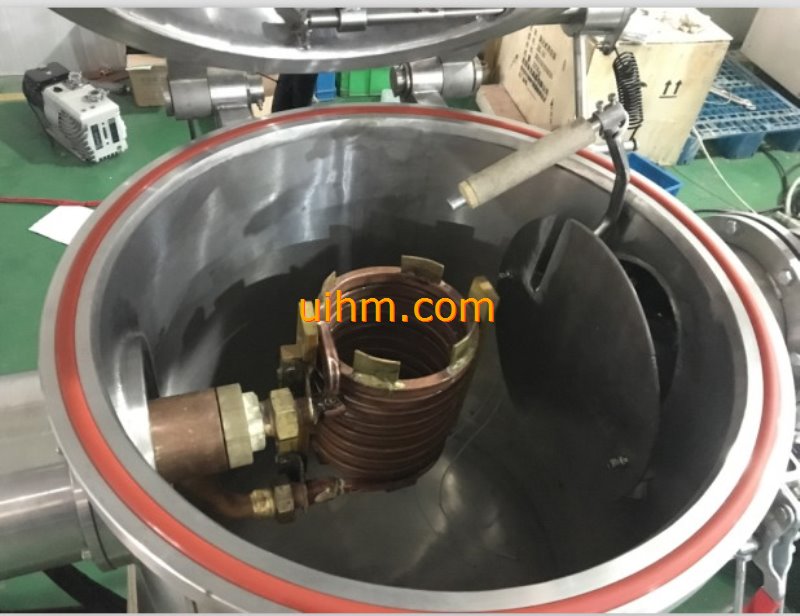

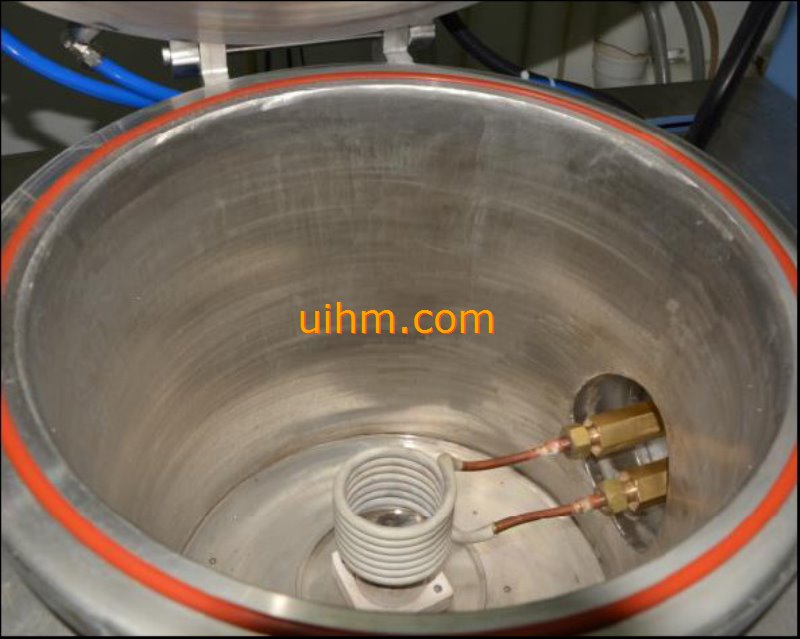

Furnace shell adopts double layer water cooling structure, swinging gear: connecting with the furnace body by flange. The induction coil made of copper tube in spiral shape is drawn out from the furnace body, with reliable Wilson seal.

Vacuum system: two stage pump, oil diffusion pump and coupled pump. There is gas-inlet and gas-outlet valve in the vacuum set.

Power supply:adopt IGBT import power element, integrated and cmpact, effective output power exceeds 90%, energy saving 60% than conventional SCR medium frequency power supply. With over current, over voltage feedback and protective circuit.

induction melting vacuum furnace

Induction Vacuum Melting Furnace (1)

Induction Vacuum Melting Furnace (2)

Induction Vacuum Melting Furnace (3)

Induction Vacuum Melting Furnace (4)

induction vacuum melting machine

vacuum induction melting machine with casting function_1

vacuum induction melting machine with casting function_2

vacuum induction melting machine with casting function_3

Newest Comment

One of our valued clients have raised the above cited inquiry for:

Vacuum Induction Melting and Casting Furnace

If interested, please provide your best offer in your national currency / Euro / UK Pounds etc. on or before 1 Oct 2018 (preferably earlier) and provide your point wise confirmation / responses on following clauses:

Price to be based on C&F Karachi with break-up of FOB price and ocean-freight charges and valid for 90 days

100% payment to be made through Irrevocable Letter of Credit at sight with bank charges inside Pakistan on L/c opener’s account and outside Pakistan on beneficiary’s account.

Please load 11% sales commission on top of your FOB price for us, payable after you are fully paid by the customer.

Best Regards,

Muhammad Wasim Khan

Sales Manager

HAIDER ENERGY SERVICES

64-Dastagir Centre,Agha Khan III Road,Saddar, Karachi-74400, Pakistan.

E-mail: [email protected]

WE request that you oblige us a better view and description of your induction heating machines and induction furnaces.

Also give your:

* Minimum Order Quantity

* Your earliest delivery time

* Payment terms

* And your products warranty

The melting furnace and induction forging machines we are asking you to make for, we have previously been supplied by a company in Guangzhou, China.

Our first order will not exceed $ 123,200 and we intend to make 40% T / T payment available by the end of the week depend on when you reply. We await your urgent reply together with your best prizes and quotations.Have a good day.

REGARDS,

Mrs. Andrea

HEAD OFFICE

Manson Products Ltd. (Email:[email protected])

PO Box 29900, 350 Rabro Drive York Hauppauge.New, USA ..

Telephone: +1 (613) 348-0282

FAX: +1 (631) 348-0279

United Arab Emirates Office

Manson Products Ltd..

PO Box 29900, Ajman, United Arab Emirates.

Telephone: + 971 65.2088

Post Comment