-

Keywords"tin",total 1228 records

-

um-25ab-rf induction heating machine

Parameters of Radio Frequency Induction Heating Machines: Type Power Supply Input Current Output Power Max. Frequency Input Power Cooling Water …

Date:2003/02/16

-

um-25a-rf induction heating machine

Parameters of Radio Frequency Induction Heating Machines:TypePower SupplyInput CurrentOutput PowerMax. FrequencyInput PowerCooling WaterNormal Size(cm)Net Weight(kg)UM-15A-RF6KVA23A5KW60KHz220VAC, 50Hz, Single Phase>0.2 MPa, 6 L/Min, <40 C 18 X 33 X …

Date:2003/02/16

-

um-15ab-rf induction heating machine

Parameters of Radio Frequency Induction Heating Machines: Type Power Supply Input Current Output Power Max. Frequency Input Power Cooling Water …

Date:2003/02/16

-

um-15a-rf induction heating machine

Parameters of Radio Frequency Induction Heating Machines:TypePower SupplyInput CurrentOutput PowerMax. FrequencyInput PowerCooling WaterNormal Size(cm)Net Weight(kg)UM-15A-RF 15KVA 36A 8KW 60KHz 220VAC, 50Hz, Single Phase >0.2 MPa, 6 L/Min, <40 C 5…

Date:2003/02/16

-

advantages of induction heating

induction heating is a quick,safe,clean,environmentally friendly method for melting works.induction heating is able to heat different shapes of work-piece by customized induction coilsInduction heating systems do not burn traditional fossil fuels, inductio…

Date:2018/01/26

-

induction heating for cars overview of applied automotive applications

TECHNOLOGY DESCRIPTIONSurface treatment of the ring gear and subsequent hot-shrinkage on the motor flywheel.Thanks to use of the modern Termotek series, the ring gears coming from feed magazine are heated and hardened very rapidly, so that geometrical defo…

Date:2013/06/02

-

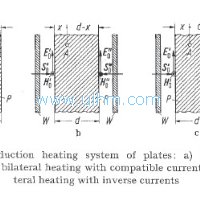

induction heating of flat objects

Contents : It is a usual procedure in industry for various machine elements like metal plates of different thickness to be heated inductively with a frequency within the range 5 ~ Hz to 3 Mttz. The paper discusses the problem of finding the best method int…

Date:2013/06/02

-

solid state technology of induction heating

Most existing annealing systems utilize multi-turn pancake style coils and are powered by large, relatively inefficient vacuum tube power supplies. The output is often inconsistent and constant adjustments are needed to maintain product quality. The IHM se…

Date:2013/06/02

-

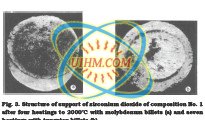

melt refractory metals with induction heating

In the Ail-Union Scientific-Research Tube Institutes industrial induction electric furnaces heated to 2000-2300C, cylindrical billets of high-melting alloys are placed on refractory supports. To select materials for the supports which do not react with mol…

Date:2013/05/16

-

induction heating for surface triggering styrene polymerization

Titanium and its alloys present high interests for technological applications due to their high resistance corrosion, mechanical properties and biocompatibility [1-5]. For example, titanium is largely used as orthopedic metallic implant [6]. In addition, T…

Date:2013/05/16

© Copyright 2025. uihm.com All Rights Reserved.