-

Keywords"induction brazing",total 222 records

-

how induction brazing works

How Induction Brazing Works Induction brazing is a process where two or more materials such as pipe are joined together with a molten space filler metal using an induction heating coil which delivers a very high temperature. The induction brazing process w…

Date:2008/02/03

-

induction brazing carbide to steel shaft

Objective Brazing a cone shaped carbide to a stainless steel shaft for a digger Material Cone shaped carbide 1.12” (28.4mm) dia, 1.5”(38.1mm) tall, stainless steel shaft 1.12” (28.4mm) dia and various length, black brazing flux and braze shims Tempera…

Date:2007/04/03

-

induction brazing thin walled tube

Objective Braze a NI-SPAN-C alloy tube to a steel cap in a hydrogen atmosphere Material NI-SPAN-C alloy tube (5mm) dia, steel cap (7mm) dia, (7mm) long, nickel braze, quartz tube and hydrogen Temperature 1875 F (1024 C) Frequency 313 kHz Equipment • P…

Date:2007/04/03

-

induction brazing piston valve

Objective Brazing a steel piston valve assembly Material Steel piston valve 4.5” dia (11.43cm), tungsten carbide plate and braze Temperature 1350 F Frequency 91 kHz Equipment • Power of 90kW induction heating system, equipped with a remote workhead c…

Date:2007/04/03

-

induction brazing brass faucet

Objective Brazing two joints on a brass bathroom faucet assembly Material Brass bathroom fittings 1” OD, brazing rings, flux Temperature 1148 F (620 C) Frequency 90 kHz Equipment • Power of 90kW induction heating system, equipped with a remote workhe…

Date:2007/04/03

-

induction brazing manufacture needles

Objective Brazing stainless steel housings to stainless steel tube for gas assembly used in the manufacturing of needles Material 2 stainless steel housings .25” (6.35mm) dia, .675 (17.1mm) & .54” (13.7mm) in length, stainless steel tube .031” (.78…

Date:2007/04/03

-

induction brazing copper pivot

Objective Brazing a copper pivot assembly Material Two copper uprights 2” (5cm) wide x 4” (10.2cm) high, copper base 3” (7.6cm) x 2” (5cm) and .5” (1.3mm) thick with 2 channels for the uprights to the slide into, braze shims and black flux Temperatu…

Date:2007/04/03

-

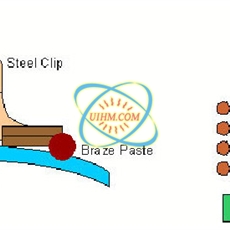

induction brazing heat-sensing probe

Objective To heat a coil and a wire assembly to 1300F (704C) within 60 seconds for brazing. Material Platinum coil, steel wire, braze paste Temperature 1300F (704C) Frequency 307kHz Equipment Power of 6KW output, remote heat station containing one 1.2 …

Date:2007/04/03

-

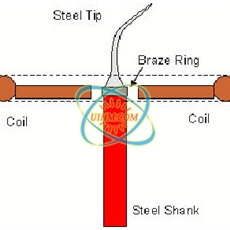

induction brazing dental tools

Objective To heat a steel tip and shank assembly to 1300F (704C) within 3 seconds for brazing with induction heating instead of torch brazing. Material 0.1” (2.54mm) diameter steel tip & shank, 0.07” (1.78mm) diameter braze ring Temperature 1300F (…

Date:2007/04/03

-

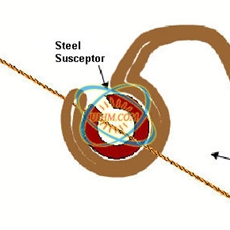

induction brazing steel orthodontic parts

Objective To heat a batch of orthodontic parts to 1300F (704C) within 1 second in an inert atmosphere for brazing. Material Small stainless steel orthodontic parts, silver braze alloy, no flux, 3 1/ 8” (79.3mm) graphite susceptor disk with 1” (25.4) cen…

Date:2007/04/03

© Copyright 2025. uihm.com All Rights Reserved.