-

Keywords"copper",total 195 records

-

induction brazing brass fitting to copper air lines

Objective To braze brass end-connectors to copper tubes used in aircraft assembly air linesMaterial brass end connectors, copper tubes of different diametersTemperature 1400 F 750CFrequency 350 kHzEquipment Power of 6KW induction heating system, including …

Date:2005/10/02

-

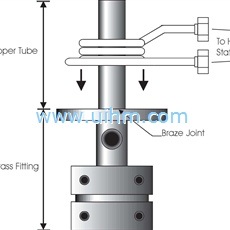

induction braze copper tube to brass fitting

Objective To use induction heating to braze a copper tube to a brass fitting using a preform braze wire. Processing is to occur under an atmosphere of Nitrogen and 4% Hydrogen gas. The braze preforms melt at 1190F, but the parts need to be kept below 1300F…

Date:2005/10/02

-

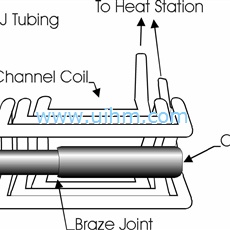

induction brazing copper tube

Objective To braze a copper tube ( 3/8″ OD by 2-4″ long) into a 3/8″ fitting in less than 10 seconds. Heating must take place in a channel type coil to allow for easy loading of parts. Material Copper Tubing and Fitting with Braze and Stay Silv White…

Date:2005/10/02

-

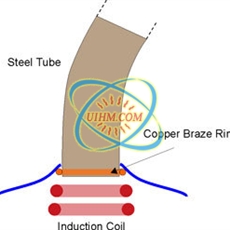

induction brazing steel tube with copper ring

Objective To heat an oil suction assembly (steel tubing and filter cap) to 1,850F (1010C) within 15 seconds for a brazing application. Material 0.125” (3.2mm) diameter steel tube and filter cap assembly, high temperature brazing flux, copper ring. Tempe…

Date:2005/10/02

-

induction annealing copper tubing

Objective To heat both ends of a copper tube to anneal as soft as possible 1.5” (38.1mm) from end and retain full hardness next to anneal Material 1.625” (41.275mm) dia x 24” (609.6mm) long copper tube Temperature 1500 F (815.5 C) Frequency 70 kHz E…

Date:2006/10/02

© Copyright 2025. uihm.com All Rights Reserved.