-

Keywords"melt",total 352 records

-

induction melting gold and silver

Melting Gold and Silver Everything for Gold and Silver Melting, it used to be that when melting gold, people used a blow torch, then a torch, then an electric melter and then an induction melter. Whatever your choice, we have the torch, the electric melter…

Date:2008/02/03

-

induction levitation melting steel balls

Levitation melting steel balls Objective Levitation of steel balls during the melting processMaterial 1010 low carbon steel balls ” (6.35mm) diameterTemperature 2800 F (1538 C)Frequency 195 kHzEquipment • Power of 30 kW induction heating system, equipped…

Date:2008/02/03

-

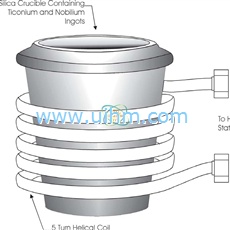

induction melting ticonium and nobilium

Melting Ticonium and Nobilium Objective: Crucible melting of Ticonium and Nobilium ingots within a period of 45 seconds. Four ingots of Nobilium are to be placed in a crucible (ID#6012) and heated, while a single ingot of Ticonium is placed in a crucible (…

Date:2008/02/03

-

induction melting aluminum for casting

Objective Heating a graphite crucible to 1292F (700C) to melt aluminum to liquid form for a casting applicationMaterial 9.8” (250mm) OD, 22.4” (570mm) long, 0.7” (17.5mm) thick Graphite crucible, approx. 92.5lb (42kg) of aluminumTemperature 1292 F (700C…

Date:2008/02/03

-

induction melting lead ingots

Melting lead ingots Objective Melting 30 lb(13.6 kg) & 60 lb(27.2 kg) lead ingots to formbattery posts & connectorsMaterial 30 lb(13.6 kg) & 60 lb(27.2 kg) lead ingots and 5” (12.7cm) IDZircar Ceramic Alumina tubeTemperature 620 FFrequency 10 …

Date:2008/02/03

-

induction crucible melting

Crucible melting Objective Heat to melting point various materials in a nitrogen atmosphere in a graphite or molybdenum crucible.Material Magnesium fluoride, tantalum pentoxide, aluminum, yttrium fluoride, germanium, hafnium or titanium dioxide and a Pyrex…

Date:2008/02/03

-

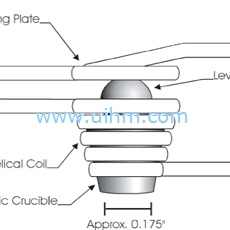

levitation induction melting system

Objective Design a modular electromagnetic levitor (MEL) to aid in the study of RF systems used to process metals in the microgravity of space. Nickel and copper are melted and levitated. A reliable system is to be developed to provide repeatable performan…

Date:2007/04/03

-

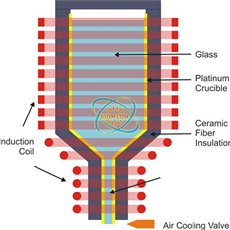

induction melting glass for fiber drawing

Objective To heat a metal susceptor vessel to 2200F within 25 minutes for a fiberglass melting application Material Metal susceptor vessel Temperature 2200F Frequency 300KHZ Equipment Power of 60 kW RF power supply, remote heat statio…

Date:2007/04/03

-

melt refractory metals with induction heating

In the Ail-Union Scientific-Research Tube Institutes industrial induction electric furnaces heated to 2000-2300C, cylindrical billets of high-melting alloys are placed on refractory supports. To select materials for the supports which do not react with mol…

Date:2013/05/16

-

how to select induction heaters for forging or melting work

Though the power factor of our IGBT or MOSFET induction heating machines can be 0.9~0.95, its hard to calculate the exact power requirement for brazing, jointing, quenching, hardening work, its often depend on experience.But there is an empirical formula (…

Date:2013/12/15

© Copyright 2025. uihm.com All Rights Reserved.