Brazing especially vacuum brazing is highly sophisticated and specialized joining process as compared to welding and other conventional methods of joining.

The brazing process is deployed when component joining becomes difficult by using the conventional methods like welding. In general, component joining can be achieved using torch brazing, induction heat brazing, under controlled atmosphere etc., however they have many limitations and are used in limited cases for many reasons.

Complex assemblies, high quality components, UHV compatible components such as for RF systems and high energy accelerators are preferably recommended to join by using vacuum brazing techniques.

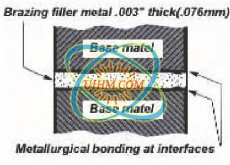

Metals and non-metals difficult-to-weld are easily joined. In vacuum brazing it is possible to produce stronger joints with no post braze cleaning. Problem of oxidation is reduced to a minimum keeping the integrity of the components intact. In this presentation under the title of "Development of Vacuum Brazing Techniques" various aspects of vacuum brazing have been covered.

It includes fundamentals of vacuum brazing, advantages of brazing specially of vacuum brazing, base and filler materials of brazing, types of brazing joints and joint design, basic parameters and steps required for brazing, operation and maintenance of vacuum brazing systems, safety aspects, assessment of joint quality of brazed joints etc. The above presentation is highly useful to the both beginners and regular users of vacuum brazing.

The brazing process is deployed when component joining becomes difficult by using the conventional methods like welding. In general, component joining can be achieved using torch brazing, induction heat brazing, under controlled atmosphere etc., however they have many limitations and are used in limited cases for many reasons.

Complex assemblies, high quality components, UHV compatible components such as for RF systems and high energy accelerators are preferably recommended to join by using vacuum brazing techniques.

Metals and non-metals difficult-to-weld are easily joined. In vacuum brazing it is possible to produce stronger joints with no post braze cleaning. Problem of oxidation is reduced to a minimum keeping the integrity of the components intact. In this presentation under the title of "Development of Vacuum Brazing Techniques" various aspects of vacuum brazing have been covered.

It includes fundamentals of vacuum brazing, advantages of brazing specially of vacuum brazing, base and filler materials of brazing, types of brazing joints and joint design, basic parameters and steps required for brazing, operation and maintenance of vacuum brazing systems, safety aspects, assessment of joint quality of brazed joints etc. The above presentation is highly useful to the both beginners and regular users of vacuum brazing.

Newest Comment

No Comment

Post Comment