Induction Hardening Surgical Knife Blades Type:

Induction Hardening Surgical Knife Blades Type:

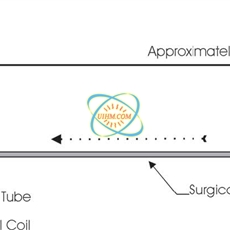

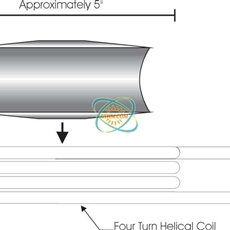

Class: Induction HardeningIntro: Objective Harden a 4″(101.6mm) section of a Stainless Steel surgical blade measuring 7″ (177.8mm) long. Hardness should be 48 to 53 Rockwell C on the blade after processing.Material 420 Stainless Steel Surgical Blades measuring 7″(177.8mm)long, 1/4″(6.…

Induction Hardening Pulleys Type:

Induction Hardening Pulleys Type:

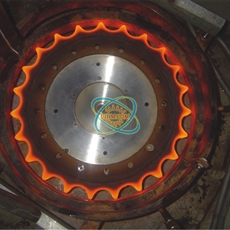

Class: Induction HardeningIntro: Objective Heat cast iron pulleys to 1600F(871.1C) in order to achieve a hardness of 55 Rockwell C.Material Ductile Iron Pulleys measuring 3 1/2″(88.9mm) OD and 2″ (50.8mm) high.Temperature 1600F (871.1C)Frequency 164 kHzEquipment • UM-UHF-10 kW inductio…

Induction Case Hardening Shaft Type:

Induction Case Hardening Shaft Type:

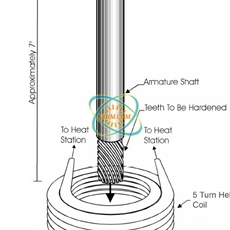

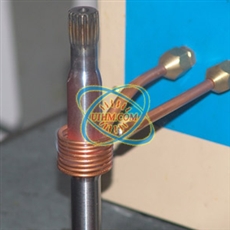

Class: Induction HardeningIntro: Case hardening shaftsObjective Harden the gear end of an armature shaft to 58-65 Rockwell C at a depth of 0.02″(.51mm) on the center line of the teeth and to 49-55 Rockwell C at a depth of .010″ (.3mm) on the center line of the root.Material Steel armatu…

Induction Hardening Steel Cam Type:

Induction Hardening Steel Cam Type:

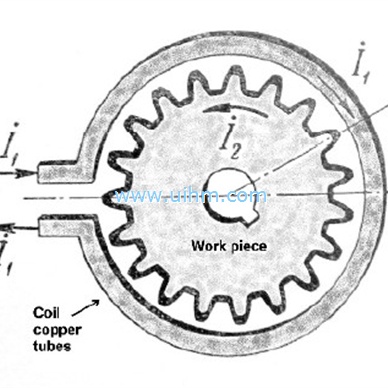

Class: Induction HardeningIntro: Objective To harden the perimeter of ” thick steel cam assembliesMaterial ” thick steel cam assemblies of varying geometriesTemperature 1650 F (900 C)Frequency 177 kHzEquipment UM-UHF-20 kW, induction heating system, equipped with a remote heat station c…

Induction Hardening Steel Type:

Induction Hardening Steel Type:

Class: Induction HardeningIntro: Objective To harden various size ends of hand held marking stamps. The area to be hardened is 3/4” (19mm) up the shank.Material Steel stamps 1/4” (6.3mm), 3/8” (9.5mm), 1/2” (12.7mm) and 5/8” (15.8mm) squareTemperature 1550 F (843 C)Frequency 99 kHzEq…

Induction Hardening steel screw threads or steel nails Type:

Induction Hardening steel screw threads or steel nails Type:

Class: Induction HardeningIntro: Objective Heat steel roofing screw to 1650 F to harden the threadsMaterial Steel roofing screws of varying diameters less than 1.25” (31.75mm) diameter, 5” (127mm) longTemperature 1650 F (899 C)Frequency 291 kHzEquipment • UM-UHF-6 kW induction heating …

INDUCTION HARDENING AND FLAME HARDENING Type:

INDUCTION HARDENING AND FLAME HARDENING Type:

Class: Induction HardeningIntro: WHAT ARE THE TREATMENTS?Induction hardening and flame hardening are methods for hardening the surfaces of components, usually in selected areas, by the short-time application of high-intensity heating followed by quenching. The heating and hardening effec

Induction HARDENING AND TEMPERING OF TOOLS Type:

Induction HARDENING AND TEMPERING OF TOOLS Type:

Class: Induction HardeningIntro: WHAT ARE THE STEELS?Tool and die steels are covered in BS 4659:1989, although both American nomenclature and a variety oftrade names are also in use. Available in high-quality grades, these specifically-designed steels can be groupedbroadly according to t

Effect of surface hardening by induction heating Type:

Effect of surface hardening by induction heating Type:

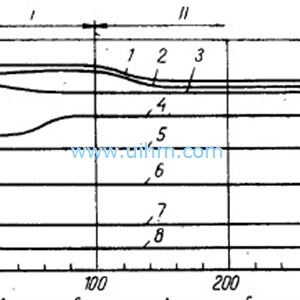

Class: Induction HardeningIntro: Surface hardening of carbon steel by high frequency induction heating (HFIH) produces a considerable increase in its resistance to stress corrosion [1, 2]. The magnitude of this increase depends on the depth of surface hardening, on the strength of the sp

Induction surface hardening Type:

Induction surface hardening Type:

Class: Induction HardeningIntro: Induction Surface HardeningKelvin Effect, Mean Curvatures and Load Impedance in Surface Induction Hardening: AnAnalytical Approach including Magnetic LossesAbstract– Kelvin effect (Skin effect) is used in surface hardening produced by induction heating of