Induction heating is often used in the heat treatment of metal items. The most common applications are induction hardening of steel parts, induction soldering/brazing as a means of joining metal components and induction annealing to selectively soften an area of a steel part.

Induction heating can produce high power densities which allow short interaction times to reach the required temperature. This gives tight control of the heating pattern with the pattern following the applied magnetic field quite closely and allows reduced thermal distortion and damage.

This ability can be used in hardening to produce parts with varying properties. The most common hardening process is to produce a localised surface hardening of an area that needs wear-resistance, while retaining the toughness of the original structure as needed elsewhere. The depth of induction hardened patterns can be controlled through choice of induction-frequency, power-density and interaction time.

Induction heating can produce high power densities which allow short interaction times to reach the required temperature. This gives tight control of the heating pattern with the pattern following the applied magnetic field quite closely and allows reduced thermal distortion and damage.

This ability can be used in hardening to produce parts with varying properties. The most common hardening process is to produce a localised surface hardening of an area that needs wear-resistance, while retaining the toughness of the original structure as needed elsewhere. The depth of induction hardened patterns can be controlled through choice of induction-frequency, power-density and interaction time.

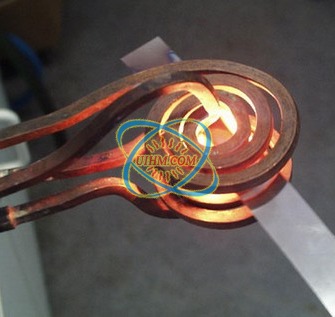

Band induction Heating

Newest Comment

No Comment

Post Comment