heat-treatment1

Generally steels are a suitable substance that goes under such treatments, since it responds well to it.

Common Heat Treatments:

Hardening

Softening

Material Modification

Hardening is generally done in order to enhance the wear and strength properties of the metal, especially steel. Sufficient alloy and carbon are the primary things or the pre-requisites for hardening.

Softening is exactly done for getting the opposite properties of a substance. It is done so that the strength and hardness of the material can be reduced.

Material modification is simply done to adjust the properties of the materials in addition with the softening and hardening procedures.

Stages of Heat Treatment:

This process can be skilled in three stages which are as follows:

First Stage – Heat the metal or the substance slowly in order to ensure a consistent temperature.

Second Stage ?Soaking of the metal at a particular given temperature for a specific time and then cooling down the metal to room temperature.

Third Stage ?Chilling the metal to room temperature.

As far as this treatment is concerned, maintaining uniform temperatures at all levels is the primary objective of the treatment process. Because of the uneven heating, one part can expand faster as compared to the other; therefore it may result in cracking or distortion. Moreover, uniform temperature can be achieved by heating the metal slowly.

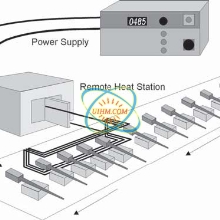

Now we come to a very important aspect of the method of heat treating which is, for a thriving treatment process a close control is required over all the factors affecting the heating and cooling, however this can only be done with proper equipments.

Heat Treatment Processes:

If we talk about these treatment processes there are a wide range of them:

Ageing

Hardening

Normalizing

Induction Hardening

Annealing

Tempering

Isothermal Transformation

Cyaniding

Case Hardening

Shot Blasting etc.

In general, Annealing is the opposite process of hardening which when done relieves internal stress and soften the metal in order to make it more ductile. It refers to heating the metal to a specific temperature and holding it for a set of time and then cooling it to the room temperature.

Newest Comment

No Comment

Post Comment