- HF Induction Brazing

- ┣━━ HF Induction Brass Solder

- MF Induction Forging

- Induction Hardening

- HF Induction Quenching

- HF Induction Annealing

- Induction Tempering or Preheating

- Induction Melting

- ┣━━ Rare Metals Melting

- ┣━━ High Capacity Melting

- Induction Shrink Fitting

- Induction Thermal Treatment

- Induction Heating for Aerospace

- Induction Bonding

- Induction Soldering

- Induction Welding

- Induction Jointing

- Other Induction Applications

-

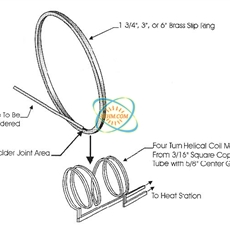

Induction Soldering brass rings

Soldering brass rings Objective: To heat 1 3/4, 3 and 6 diameter brass slip rings and a sheathed copper wire assembly to 3600 F for soldering within three (3) to six (6) seconds. Currently production is accomplished by using a soldering iron and stick…

2008/02/03

-

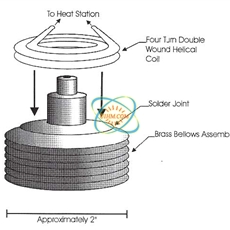

Induction Soldering Brass Bellows Assembly

Soldering Brass Bellows Assembly Objective: To heat a brass bellows and end cap assembly to 450F for soldering within 20 seconds. Presently, a soldering iron is used to produce the joint between the bellows and cap. The customer requests a quality sol…

2008/02/03

-

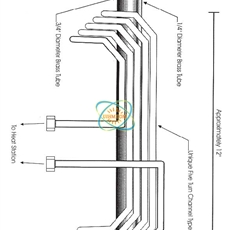

Induction Soldering brass tubes

Soldering brass tubes Objective: Soldering two brass tubes measuring 3/4 and 1/4 together for use as cellular phone antennas. The lengths of tubes range from four (4) feet to twelve (12) feet, and must be soldered along the axial side. The joint is to…

2008/02/03

-

Induction Brazing brass faucet

Objective Brazing two joints on a brass bathroom faucet assemblyMaterial Brass bathroom fittings 1” OD, brazing rings, fluxTemperature 1148 F (620 C)Frequency 90 kHzEquipment • UM-HF-90kW induction heating system, equipped with a remote workhead containi…

2007/04/03

-

Induction Brazing copper pivot

Objective Brazing a copper pivot assemblyMaterial Two copper uprights 2” (5cm) wide x 4” (10.2cm) high, copper base 3” (7.6cm) x 2” (5cm) and .5” (1.3mm) thick with 2 channels for the uprights to the slide into, braze shims and black fluxTemperature 1…

2007/04/03

-

Induction Brazing copper joints

Objective Brazing a joint between a copper lug and nickel plated copper pins on a pressurized heater connector.Material 1.5” (38.1mm) dia heater connector in a ceramic insulator with L shaped copper lugs and nickel plated copper pins, silver solder and br

2007/04/03

-

Induction Brazing Copper Contacts

Objective Heat silver contacts and brass/copper bus for brazing applicationMaterial Silver contact .75 (19mm) diameter, brass and copper bus 2” x 1” (50.8 x 25.4mm), braze shims, white fluxTemperature 1300 F (704 C)Frequency 320 kHzEquipment • UM-UHF-10…

2005/10/03

-

Induction Brazing Brass Trap Block

Objective Block is heated to 1400F to braze trap tube to assemblyMaterial brass block and pre-formed tubesbraze pre-formsTemperature 1400 F (760C)Frequency 357 kHzEquipment UM-UHF-20kW induction heating system including• Coil: custom-designed 2-turn split

2005/10/02

-

Induction brazing copper to copper

Objective To braze copper to copper bus bar assemblies togetherMaterial • 2 copper bus bars 6” (152.4mm) wide, 2’ (609.6mm)long, 2 copper bars 6”(152.4mm) wide, 18” (457.2)long & 3/8” (9.65mm) thick• braze shim preforms and white fluxTemperature…

2005/10/02

-

Induction Brazing Brass Fittings

Objective To heat brass tubing assemblies to 750C for a brazing application. The tubing diameter varies from 3 to 8 inches (76.2 to 203.2 mm)Material Brass tubingBrass flangeBraze ringsBraze fluxTemperature 1382F (750C)Frequency 100 kHzEquipment UM-HF-45

2005/10/02

© Copyright 2025. uihm.com All Rights Reserved.