- HF Induction Brazing

- ┣━━ HF Induction Brass Solder

- MF Induction Forging

- Induction Hardening

- HF Induction Quenching

- HF Induction Annealing

- Induction Tempering or Preheating

- Induction Melting

- ┣━━ Rare Metals Melting

- ┣━━ High Capacity Melting

- Induction Shrink Fitting

- Induction Thermal Treatment

- Induction Heating for Aerospace

- Induction Bonding

- Induction Soldering

- Induction Welding

- Induction Jointing

- Other Induction Applications

-

Induction Brazing Brass Fitting to Copper Air Lines

Objective To braze brass end-connectors to copper tubes used in aircraft assembly air linesMaterial brass end connectors, copper tubes of different diametersTemperature 1400 F 750CFrequency 350 kHzEquipment UM-UHF-6KW induction heating system, including a

2005/10/02

-

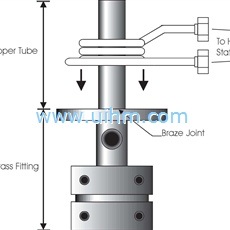

Induction Braze Copper Tube to Brass Fitting

Objective To use induction heating to braze a copper tube to a brass fitting using a preform braze wire. Processing is to occur under an atmosphere of Nitrogen and 4% Hydrogen gas. The braze preforms melt at 1190F, but the parts need to be kept below 1300

2005/10/02

-

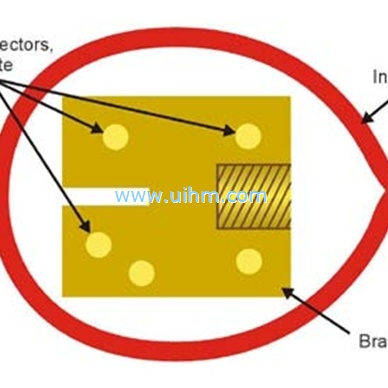

Induction Soldering Steel to Brass

ObjectiveHeat an assembly of small, gold-plated steel connectors to a brass block.Approx. 1/8” (3.2mm) diameter gold-plated steel connectors,1”(25.4mm) square x 1/4” thick brass block ,600F(315.6C),240 kHzTemperature,Frequency,Equipment6 kW induction he…

2006/03/28

-

This illustration shows how the connecting sleeve of a plate heat exchanger is inductively brazed on

This illustration shows how the connecting sleeve of a plate heat exchanger is inductively brazed on

2010/04/30

-

induction brass soldering radiator (heat sink)_2

induction brass soldering radiator (heat sink)_2

2003/08/11

© Copyright 2025. uihm.com All Rights Reserved.