- HF Induction Brazing

- ┣━━ HF Induction Brass Solder

- MF Induction Forging

- Induction Hardening

- HF Induction Quenching

- HF Induction Annealing

- Induction Tempering or Preheating

- Induction Melting

- ┣━━ Rare Metals Melting

- ┣━━ High Capacity Melting

- Induction Shrink Fitting

- Induction Thermal Treatment

- Induction Heating for Aerospace

- Induction Bonding

- Induction Soldering

- Induction Welding

- Induction Jointing

- Other Induction Applications

-

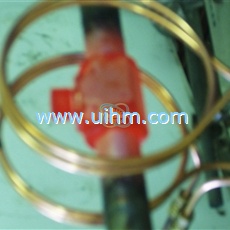

Induction Brazing brass faucet

Objective Brazing two joints on a brass bathroom faucet assemblyMaterial Brass bathroom fittings 1” OD, brazing rings, fluxTemperature 1148 F (620 C)Frequency 90 kHzEquipment • UM-HF-90kW induction heating system, equipped with a remote workhead containi…

2007/04/03

-

Induction Brazing manufacture needles

Objective Brazing stainless steel housings to stainless steel tube for gas assembly used in the manufacturing of needlesMaterial 2 stainless steel housings .25” (6.35mm) dia, .675 (17.1mm) & .54” (13.7mm) in length, stainless steel tube .031” (.78mm…

2007/04/03

-

Induction Brazing copper pivot

Objective Brazing a copper pivot assemblyMaterial Two copper uprights 2” (5cm) wide x 4” (10.2cm) high, copper base 3” (7.6cm) x 2” (5cm) and .5” (1.3mm) thick with 2 channels for the uprights to the slide into, braze shims and black fluxTemperature 1…

2007/04/03

-

Induction Brazing heat-sensing probe

Objective To heat a coil and a wire assembly to 1300F (704C) within 60 seconds for brazing.Material Platinum coil, steel wire, braze pasteTemperature 1300F (704C)Frequency 307kHzEquipment UM-UHF-6KW output, remote heat station containing one 1.2 microfara

2007/04/03

-

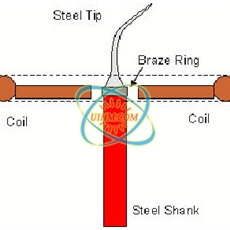

Induction Brazing dental tools

Objective To heat a steel tip and shank assembly to 1300F (704C) within 3 seconds for brazing with induction heating instead of torch brazing.Material 0.1” (2.54mm) diameter steel tip & shank, 0.07” (1.78mm) diameter braze ringTemperature 1300F (704C…

2007/04/03

-

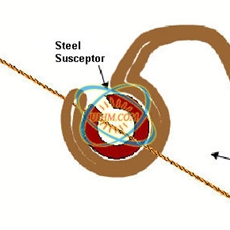

Induction Brazing steel orthodontic parts

Objective To heat a batch of orthodontic parts to 1300F (704C) within 1 second in an inert atmosphere for brazing.Material Small stainless steel orthodontic parts, silver braze alloy, no flux, 3 1/ 8” (79.3mm) graphite susceptor disk with 1” (25.4) cente…

2007/04/03

-

Induction Brazing steel tube

Objective To braze a steel tube to a steel “T” fittingMaterial 1” (25.4mm) diameter steel tubing, steel fitting, braze slug and black fluxTemperature 1400F (760C)Frequency 198 kHzEquipment • UM-UHF-15kW induction heating system, equipped with remote …

2007/04/03

-

Induction Brazing stainless steel dental assembly

Objective To heat a steel dental assembly to 1400F (760C) for brazingMaterial Stainless steel plates 0.118” (3mm) square and 0.078” (2mm) high, stainless steel hook, mesh, two pieces of graphite 0.375”(9.5mm) square cross section, 4” (101.6mm) long and…

2007/04/03

-

Induction Brazing aluminum tubing

Objective Heat aluminum for an automotive brazing applicationMaterial Aluminum tubing 0.50 (12.7mm) dia, an aluminum boss 1”(25.4mm) long, flux filled braze ringsTemperature 1200 F (649 C)Frequency 270 kHzEquipment •UM-UHF-10kW induction heating system, …

2007/04/03

-

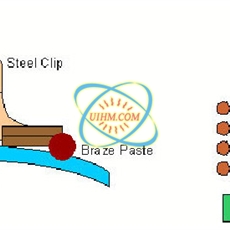

Induction Brazing steel mold

Objective Heating steel golf ball mold to brazing dimple insertMaterial Golf ball mold 2” in diameter, braze flux paste, dimple insertTemperature 1400 F (760 C)Frequency 206 kHzEquipment • UM-UHF-20 kW induction heating system, equipped with a remote wor…

2007/04/03

© Copyright 2025. uihm.com All Rights Reserved.