- HF Induction Brazing

- ┣━━ HF Induction Brass Solder

- MF Induction Forging

- Induction Hardening

- HF Induction Quenching

- HF Induction Annealing

- Induction Tempering or Preheating

- Induction Melting

- ┣━━ Rare Metals Melting

- ┣━━ High Capacity Melting

- Induction Shrink Fitting

- Induction Thermal Treatment

- Induction Heating for Aerospace

- Induction Bonding

- Induction Soldering

- Induction Welding

- Induction Jointing

- Other Induction Applications

-

Induction Soldering brass

Soldering brass Objective To solder a brass end cap to a series of copper tubesMaterial Preassembled heat exchanger with copper tubes and 2 brass end caps 2.36” (60mm) OD, 0.08” to 0.12” (2 to 3mm) thick at both ends, liquid solderTemperature 302F …

2008/02/03

-

Induction Soldering brass and copper

Soldering brass and copper Objective To heat brass and copper for soldering application on medical equipmentMaterial Brass ring, brass and copper pieces 5.11” (130mm) long, 4.3” (110mm) OD & 0.3” (7mm) at thickest point and solder ringsTemperat…

2008/02/03

-

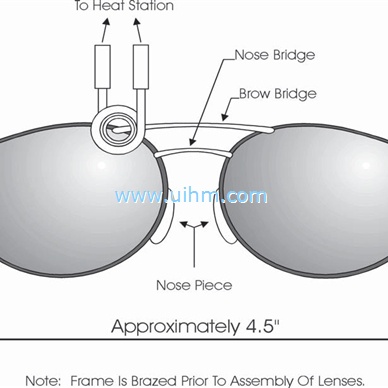

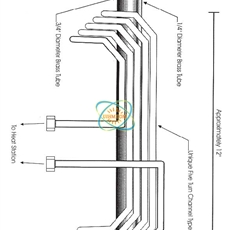

Induction Soldering brass rings

Soldering brass rings Objective: To heat 1 3/4, 3 and 6 diameter brass slip rings and a sheathed copper wire assembly to 3600 F for soldering within three (3) to six (6) seconds. Currently production is accomplished by using a soldering iron and stick…

2008/02/03

-

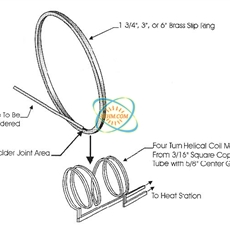

Induction Soldering Brass Bellows Assembly

Soldering Brass Bellows Assembly Objective: To heat a brass bellows and end cap assembly to 450F for soldering within 20 seconds. Presently, a soldering iron is used to produce the joint between the bellows and cap. The customer requests a quality sol…

2008/02/03

-

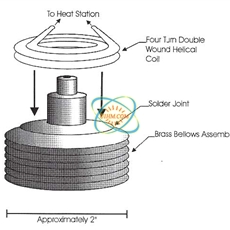

Induction Soldering brass tubes

Soldering brass tubes Objective: Soldering two brass tubes measuring 3/4 and 1/4 together for use as cellular phone antennas. The lengths of tubes range from four (4) feet to twelve (12) feet, and must be soldered along the axial side. The joint is to…

2008/02/03

-

Induction Solder Flex Circuits

Solder Flex Circuits Objective To heat multiple joints on flex circuit strips to 180-200F within seven seconds for a soldering application.Material Copper bonded to polyester flex circuit strips, Solder Plus Paste 63NC-A, 0.0625” thick Teflon sheetsT…

2008/02/03

-

Induction Heat Television Picture Tube Glass

Heat Television Picture Tube Glass Objective: The incorporation of solid state RF induction heating into the television picture tube industry, specifically the insertion of attachment pins into the already formed picture tube glass panel. Four pins ar…

2008/02/03

-

Induction Brazing carbide to steel shaft

Objective Brazing a cone shaped carbide to a stainless steel shaft for a diggerMaterial Cone shaped carbide 1.12” (28.4mm) dia, 1.5”(38.1mm) tall, stainless steel shaft 1.12” (28.4mm) dia and various length, black brazing flux and braze shimsTemperature…

2007/04/03

-

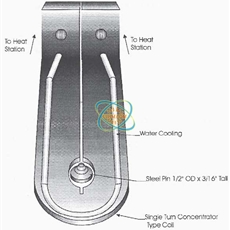

Induction Brazing thin walled tube

Objective Braze a NI-SPAN-C alloy tube to a steel cap in a hydrogen atmosphereMaterial NI-SPAN-C alloy tube (5mm) dia, steel cap (7mm) dia, (7mm) long, nickel braze, quartz tube and hydrogenTemperature 1875 F (1024 C)Frequency 313 kHzEquipment • UM-UHF-20

2007/04/03

-

Induction Brazing piston valve

Objective Brazing a steel piston valve assemblyMaterial Steel piston valve 4.5” dia (11.43cm), tungsten carbide plate and brazeTemperature 1350 FFrequency 91 kHzEquipment • UM-HF-90kW induction heating system, equipped with a remote workhead containing s…

2007/04/03

© Copyright 2025. uihm.com All Rights Reserved.