Induction heating has been used extensively for heat treating processes in a variety of metalworking applications.Some of these applications are associated with discrete parts such as shafts, bearings, gears, and hubs. Here, the most common processes are hardening and tempering of carbon and alloy steel parts to improve strength and wear characteristics.

However, many induction heating applications are associated with in-line heat treating processes to permit high speed production of both ferrous and nonferrous plate and strip products. Here, often a wider range of heat treat processes are required to permit subsequent manufacturing operations such as rolling, forming, and joining, as well as to improve the mechanical properties of the final product. These in-line processes include partial and full annealing, normalizing, hardening, tempering, and even solution heat treating (in the case of some nonferrous products).

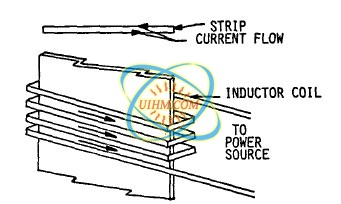

Induction heating provides a very efficient method of heating magnetic strip. Here, heating is readily applied by using longitudinal flux that is created by a solenoid type inductor coil that encircles the strip to be heated. The solenoid coil magnetically couples to the strip, creating a circulating current that flows across the width of the strip and returns on itself on the opposite side as shown in Figure 1. Even for relatively thin magnetic strip, good efficient heating can be maintained since the depth of current penetration is small, and, therefore, it does not cancel itself as it returns on the opposite side of the strip. This method of heating is ideally suited for magnetic strip and even

for nonmagnetic strip that has a higher electrical resistivity and part thickness. However, as the strip gets thinner, higher frequencies must be used to maintain a good transfer of energy from the coil to the strip as shown in Table 1. And, for low resistivity materials, such as aluminum, copper, and brass, both the efficiency and power factor are at significantly lower levels than for ferrous products.

As a result, an alternative method known as transverse flux induction heating offers considerable benefits for in-line strip heating applications. This method of heating has been known for many years; however, it requires specially designed iron cored laminated inductor coils and tighter control of the power, strip handling, and process parameters.

It has been in recent years that advancements in solid-state power sources and closed-loop process control have provided the parameters for productizing the transverse flux technology. While there is no basic improvement

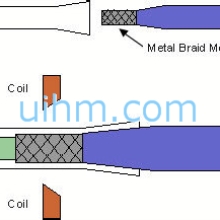

in the heating efficiency of magnetic strip, there can be benefits in capital equipment costs, since lower frequencies can be used on the thinner strip. However, lower frequencies do impart more magnetic force and can produce undesirable vibrations in the material as it passes through the inductor coil pole faces. Transverse flux develops a current pattern in the strip as shown in Figure 2. Here, it is across the width of the strip and returns a pole-pitch distance down the length of the strip. This eliminates the current cancellation problem associated with longitudinal flux heating, providing optimum heating efficiency and coil power factor. It also permits use of lower frequency power sources as shown in Table 2. And, with this type of heating, further latitude in frequency selection is possible, since other parameters can be varied to provide good coil efficiency and power factor

Newest Comment

No Comment

Post Comment