- HF Induction Brazing

- ┣━━ HF Induction Brass Solder

- MF Induction Forging

- Induction Hardening

- HF Induction Quenching

- HF Induction Annealing

- Induction Tempering or Preheating

- Induction Melting

- ┣━━ Rare Metals Melting

- ┣━━ High Capacity Melting

- Induction Shrink Fitting

- Induction Thermal Treatment

- Induction Heating for Aerospace

- Induction Bonding

- Induction Soldering

- Induction Welding

- Induction Jointing

- Other Induction Applications

-

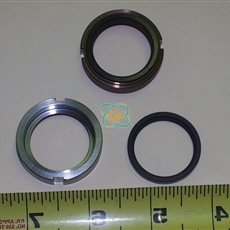

Induction Shrink Fit Bearings

Shrink Fit Bearings Objective To heat a roller bearing assembly for a shrink fitting applicationMaterial Steel bearings, diameters 1” to 3.5” (25.4 to 89mm)Temperature 300F (150C)Frequency 60 kHzEquipment Power of 25kW solid-state induction power su…

2008/02/03

-

Induction Shrink Fit Steel Flange

Shrink Fit Steel Flange Objective To heat steel flange for heat shrink application. Reaching the desired temperature results in adequate expansion to allow for placing of the flange over a graphite seal.Material Graphite seal 1” (25.4mm) diameter ste…

2008/02/03

-

Induction Shrink Fit Steel Tube

Shrink Fit Steel Tube Objective Heating a steel tube to 500-1000F for a shrink-fitting application. Determine expansion (growth) of ID at varying temperatures.Material Steel tubes 7” OD x 4.75” ID x 5” heat zone Type ‘K’ thermocouple to measure t…

2008/02/03

-

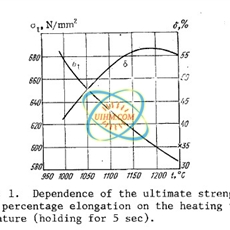

INDUCTION HARDENING OF BEARING PARTS

INDUCTION HARDENING OF BEARING PARTS It is known that induction heating is effective in flow-line mass production that precludesresetting of equipment, or in individual production where the application of ordinaryheating methods is difficult.Induction…

2008/02/03

-

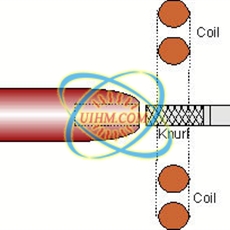

HEAT TREATMENT WITH INDUCTION HEATING OF WITHIN PIPES

HEAT TREATMENT WITH INDUCTION HEATING OF WITHIN PIPES Electrically welded pipes with an external diameter of 16-102 mm made from corrosionresistantsteels of the austenitic class after having been made on argon-arc welding mill(AAW) are at present heat…

2008/02/03

-

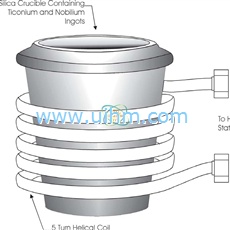

Induction Melting Ticonium and Nobilium

Melting Ticonium and Nobilium Objective: Crucible melting of Ticonium and Nobilium ingots within a period of 45 seconds. Four ingots of Nobilium are to be placed in a crucible (ID#6012) and heated, while a single ingot of Ticonium is placed in a cruci…

2008/02/03

-

Induction Melting aluminum for casting

Melting aluminum for casting Objective Heating a graphite crucible to 1292F (700C) to melt aluminum to liquid form for a casting applicationMaterial 9.8” (250mm) OD, 22.4” (570mm) long, 0.7” (17.5mm) thick Graphite crucible, approx. 92.5lb (42kg) o…

2008/02/03

-

Induction Melting lead ingots

Melting lead ingots Objective Melting 30 lb(13.6 kg) & 60 lb(27.2 kg) lead ingots to formbattery posts & connectorsMaterial 30 lb(13.6 kg) & 60 lb(27.2 kg) lead ingots and 5” (12.7cm) IDZircar Ceramic Alumina tubeTemperature 620 FFrequenc…

2008/02/03

-

Induction Crucible melting

Crucible melting Objective Heat to melting point various materials in a nitrogen atmosphere in a graphite or molybdenum crucible.Material Magnesium fluoride, tantalum pentoxide, aluminum, yttrium fluoride, germanium, hafnium or titanium dioxide and a …

2008/02/03

-

Induction Bonding plastic handle to knife

Bonding plastic handle to knife Objective Bonding handle of a stainless steel surgical knife into a plastic handleMaterial Plastic tool handle, 0.125” (3.18mm) diameter steel knifeTemperature 450 F (232 C)Frequency 390 kHzEquipment • Power of 6 kW i…

2008/02/03

© Copyright 2025. uihm.com All Rights Reserved.