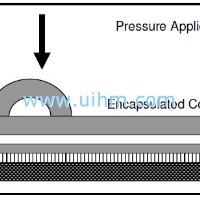

Objective Bonding handle of a stainless steel surgical knife into a plastic handle

Material Plastic tool handle, 0.125” (3.18mm) diameter steel knife

Temperature 450 ºF (232 ºC)

Frequency 390 kHz

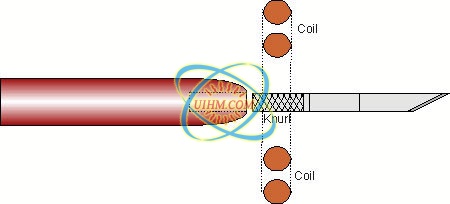

Equipment • Power of 6 kW induction heating system, equipped with a remote workhead containing one 0.66μF capacitor.

• An induction heating coil designed and developed specifically for this application.

Process A four turn split helical coil is used for this application. Power is applied to the steel knife for 2.0 seconds to reach 450 ºF (232 ºC). The steel knife is then inserted into the plastic handle to create a solid bond.

Results/Benefits Induction heating provides:

• Fast, accurate, repeatable heat

• Able to heat very small areas within precise production tolerances

• Hands-free heating that involves no operator skill for manufacturing

• Even distribution of heating

Bonding plastic handle to knife

Newest Comment

No Comment

Post Comment