Objective: Bond an aluminium mesh to a plastic beer keg

Objective: Bond an aluminium mesh to a plastic beer kegMaterial : Aluminium mesh

. Plastic keg 320 mm (12.5”) ID

Temperature 250 C (482 F)

Frequency 200 kHz

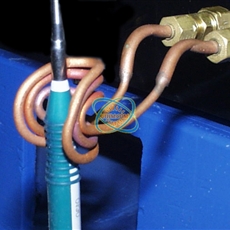

Equipment UM-10AB-UHF, induction heating system, equipped with a remote workhead containing two .33μF capacitors (for a total of .66 μF).

An induction heating coil designed and developed specifically for this application.

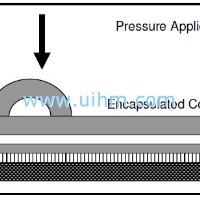

Process/Narrative A single-turn solenoid coil is placed around the assembled

beer keg and heated for 35 seconds as the keg is rotated.

Pressure is applied with a press on the top rim whilst the keg is

rotating, forming a seal between the aluminium mesh and the two halves of the beer keg.

Results/Benefits Induction heating provides:

. Quick, reliable, repeatable heat

. Localized, precision heat to the mesh area

Newest Comment

No Comment

Post Comment